The Rise of Highway Guardrail Making Machines A Factory Perspective

Highway safety is an integral concern for governments and transportation authorities worldwide. As traffic volumes increase and infrastructure ages, the demand for effective safety solutions has never been greater. One of the most essential components in highway safety systems is guardrails. The production of guardrails relies heavily on advanced machinery, specifically designed for this purpose. In recent years, the evolution of highway guardrail making machines has transformed the manufacturing process, leading to enhanced efficiency, quality, and safety.

Understanding Highway Guardrails

Highway guardrails are barriers that are installed along highways to prevent vehicles from veering off the road and into dangerous areas, such as steep drops or oncoming traffic. They absorb energy during crashes and redirect vehicles back onto the roadway, significantly mitigating the impact of accidents. The importance of these structures cannot be overstated; they save lives and reduce the severity of injuries in vehicle collisions.

The Role of Guardrail Making Machines

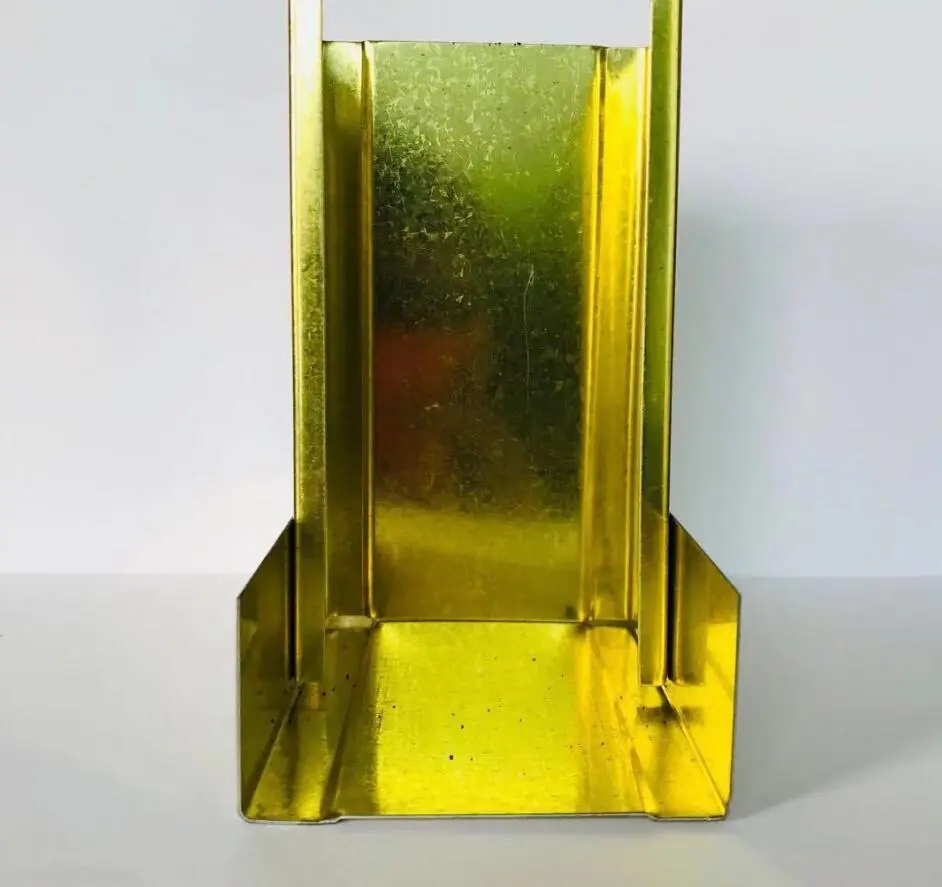

The manufacturing of highway guardrails involves several stages, from steel processing to the final assembly of guardrail sections. Highway guardrail making machines simplify this complex process by automating key manufacturing steps. These machines are designed to cut, bend, and assemble various materials, usually steel, into guardrail sections that meet strict safety standards.

Modern factories that produce guardrails utilize state-of-the-art guardrail making machines to enhance productivity. These machines are equipped with computer numerical control (CNC) technology, allowing for precise cutting and shaping of materials. This level of accuracy not only improves the quality of the final product but also minimizes waste, making the manufacturing process more sustainable.

Features of Advanced Guardrail Making Machines

1. Automation Advanced machinery is often fully automated, reducing the need for manual labor and increasing production speed. This transition to automation also helps mitigate human error, resulting in higher consistency in product quality.

2. Customization With today’s guardrail making machines, manufacturers can easily adjust settings to create different types of guardrails. This flexibility is essential for meeting specific regulatory requirements or adapting to various highway conditions.

3. Material Efficiency Modern machines optimize material use by minimizing scrap and utilizing advanced cutting techniques. This not only reduces costs but also supports eco-friendly manufacturing practices.

4. Safety Features Safety is paramount in any manufacturing environment. Newer guardrail making machines come equipped with improved safety features, ensuring that operators work in a secure environment, thus reducing workplace accidents.

The Manufacturing Process

In a typical manufacturing factory, the process begins with the acquisition of raw materials, often in the form of steel coils. The highway guardrail making machines convert these coils into guardrails through a series of steps that include

- Cutting The steel is cut to specified lengths using high-precision cutting tools. - Bending The cut pieces are then bent into the required shapes using hydraulic or mechanical bending machines. - Finishing Finally, the sections are cleaned, coated with protective finishes, and inspected for quality assurance.

The Impact of Technology on Manufacturing

The integration of technology into guardrail production has led to significant advancements. For example, the use of artificial intelligence (AI) and machine learning algorithms optimizes production schedules and maintenance cycles, further enhancing efficiency. Factories can monitor machine performance in real-time, predicting failures before they occur and minimizing downtime.

Conclusion

The highway guardrail making machine factory represents an essential component of modern infrastructure development. As safety standards continue to evolve, these machines will play a crucial role in ensuring that highways remain safe for drivers and pedestrians alike. With advancements in technology and manufacturing processes, the future of highway guardrail production looks promising, paving the way for safer roads and reduced accident rates. As we move forward, investing in these advanced machines will not only improve manufacturing efficiency but will also contribute significantly to public safety, demonstrating the intrinsic link between technology and infrastructure development.