In the world of modern construction, efficiency and precision in roofing installations are paramount. The double layer roofing sheet forming machine stands as a cutting-edge innovation addressing these needs. By comprehending its mechanics and embracing its benefits, industry professionals can enhance both their expertise and reliability in delivering top-notch roofing solutions.

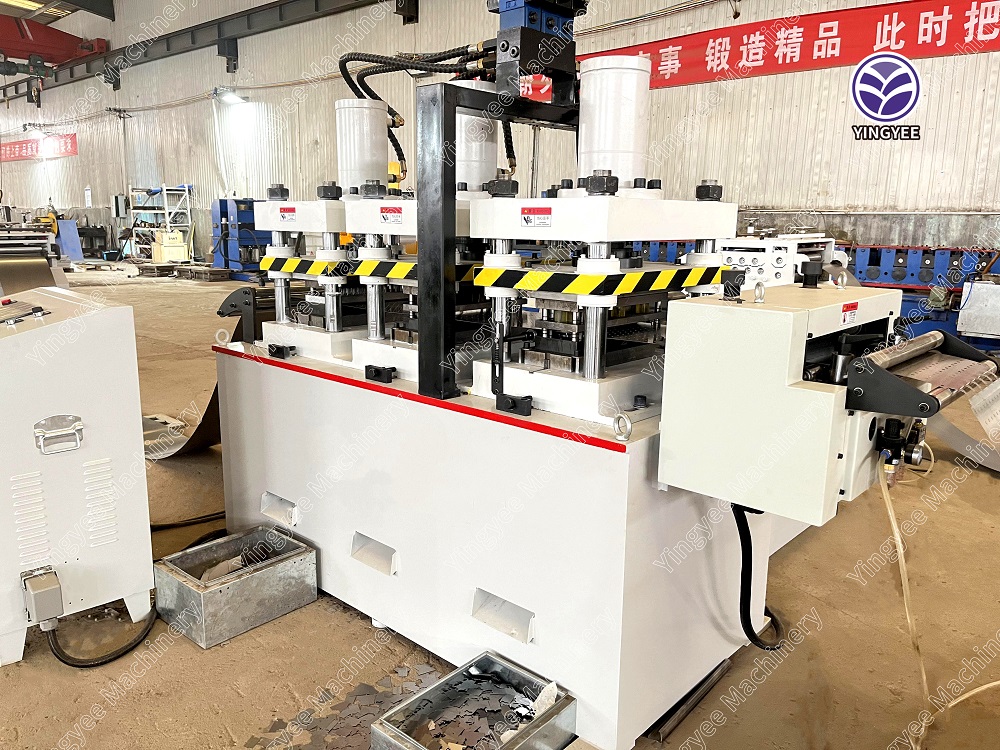

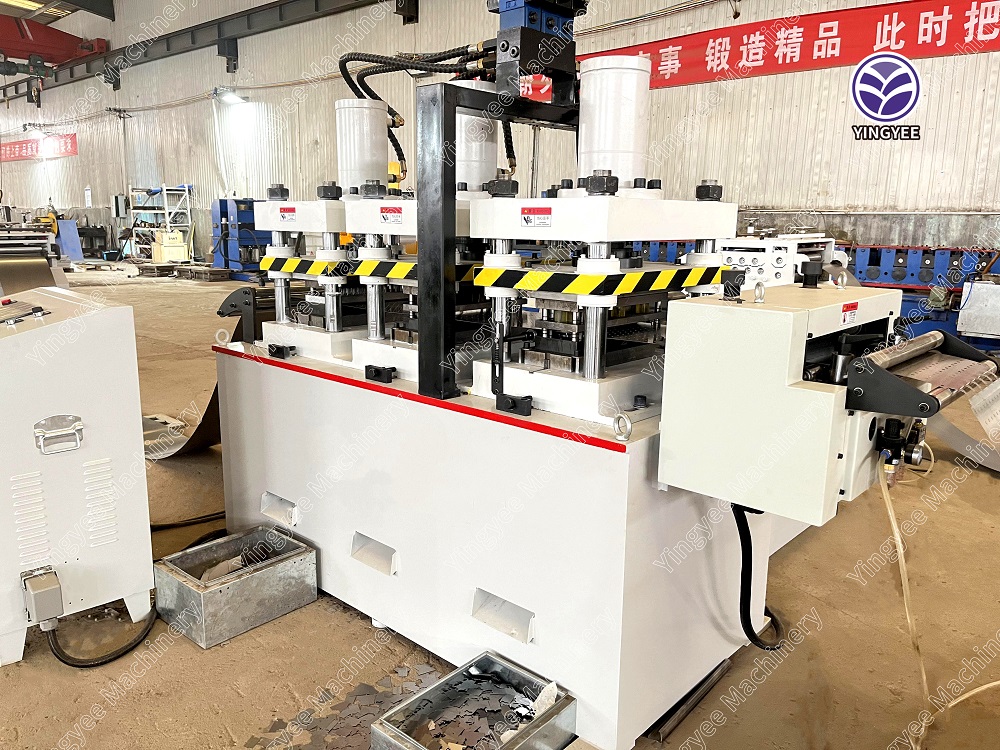

A double layer roofing sheet forming machine is an advanced piece of industrial equipment designed specifically for the fabrication of metal roofing sheets. Unlike traditional single-layer machines, this apparatus hosts dual layers, allowing it to produce two distinct profiles of roofing sheets simultaneously. This dual-functionality not only expedites the production process but also offers versatility in roof design, catering to various architectural demands without the need for multiple machines.

The strength of the double-layer technology lies in its sophisticated design and operation. At its core, the machine consists of two roll forming systems stacked one above the other. Each system can be independently calibrated, allowing for the production of different roofing profiles. This feature enables manufacturers to quickly switch between profiles, drastically reducing downtime associated with machine adjustments. The top and bottom roll forming systems are controlled through advanced computerized systems that ensure accuracy and consistency across the produced sheets.

One significant advantage of utilizing a double layer roofing sheet forming machine is its contribution to reduced material wastage. The precise nature of the forming process ensures that the metal sheets are cut and shaped with minimal excess, promoting environmental sustainability while also reducing costs for the manufacturer. Additionally, with the ability to transition between differing profiles without significant retooling, inventory management becomes more streamlined, further minimizing waste.

The expertise required to operate these machines speaks volumes about an operator's capability. Training for these machines involves understanding the nuances of computer-aided design software, mechanical proficiency in handling rolling systems, and an eye for detail in quality control. The machine operators are not merely technicians but rather specialized artisans who combine technical skill with innovative thinking to maximize the machine's potential.

double layer roofing sheet forming machine

Companies that integrate double layer roofing sheet forming machines into their production lines often find themselves at a competitive advantage. The machines not only enhance production capacity but also improve product range diversity. This flexibility allows companies to cater to niche markets demanding customized roofing solutions, thereby expanding their market reach.

Furthermore, the authoritative reputation of manufacturers who employ these advanced machines is a testament to their leadership in innovation and quality assurance. Clients can trust that the roofing sheets they purchase are engineered with precision and crafted under stringent quality controls, which is vital in an industry where the durability and longevity of roofing materials are non-negotiable.

Another aspect enhancing trustworthiness is the machine's capability to deliver consistent quality. With precise control over sheet thickness, length, and profiling, construction companies are assured of the material’s performance, which is essential for meeting safety standards and compliance regulations in construction projects. This assurance bolsters client confidence, knowing that their investment is protected through stringent manufacturing processes.

The adoption of double layer roofing sheet forming machines also reflects a commitment to technological advancements. Companies that leverage such technology showcase their dedication to continuous improvement and alignment with industry best practices. This commitment translates into a brand perception of reliability and innovation, influencing customer acquisition and retention positively.

In conclusion, a double layer roofing sheet forming machine is not merely a tool but a strategic asset in the construction sector. Its integration into production lines reflects a company's devotion to efficiency, quality, and environmental responsibility. By mastering the machine's operation, professionals not only elevate their craftsmanship but also enhance their authority and trust in the industry. As construction demands evolve, embracing such advanced manufacturing technologies becomes a pivotal factor in staying ahead of the competition and meeting the ever-growing needs of modern architecture.