The Evolution and Significance of Highway Steel Guardrail Roll Forming Machines

Highway safety is a paramount concern across the globe, and among the various safety measures implemented, guardrails play a crucial role in protecting both motorists and pedestrians. To meet the increasing demand for guardrails, innovative manufacturing techniques have emerged, one of which is the highway steel guardrail roll forming machine. This advanced technology is revolutionizing the way guardrails are produced, ensuring that they are not only efficient but also cost-effective and high in quality.

Understanding Roll Forming Technology

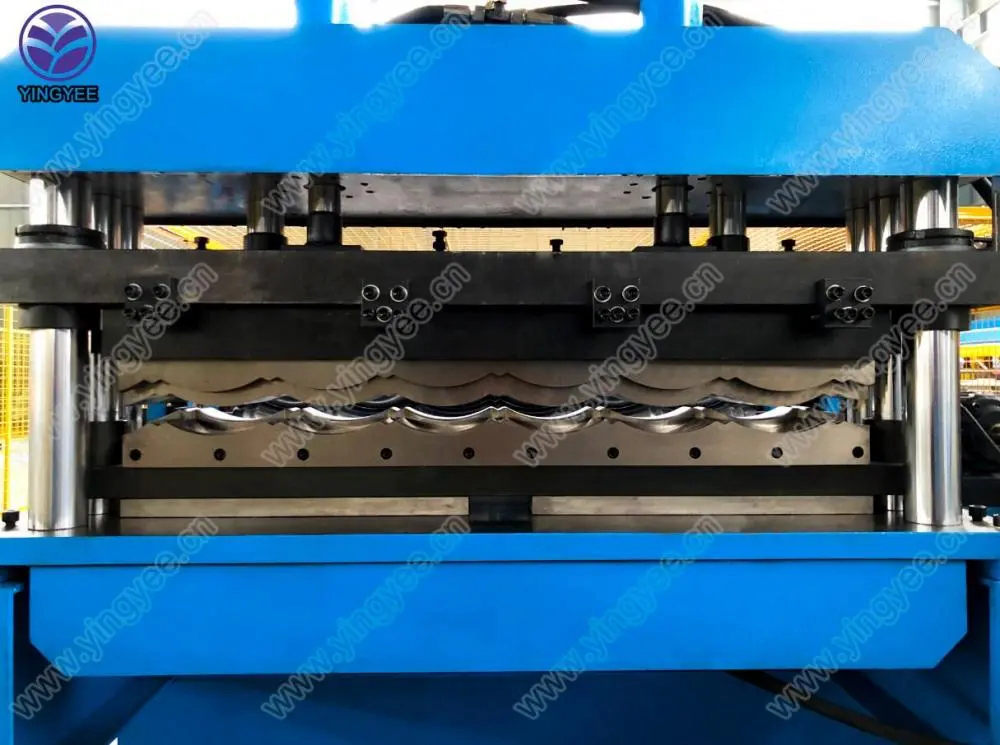

Roll forming is a continuous bending operation in which a long strip of metal is gradually shaped into the desired cross-section. This process utilizes a series of rollers to incrementally form the metal into the specific profile needed for guardrails. One of the primary advantages of using roll forming for guardrail production is its ability to produce parts with a consistent cross-section over long lengths, which is particularly beneficial for the long stretches of guardrail required on highways.

Highway steel guardrail roll forming machines are designed to handle various types of steel, including galvanized and painted materials, which offer corrosion resistance and durability. The machines utilize precise rollers and dies that can be customized to create different shapes and sizes of guardrails according to specific regulations and standards.

The Production Process

The production process begins with the feeding of steel coils into the roll forming machine. The steel is then fed through a series of powered rollers that gradually bend and shape the metal. As the steel moves through the machine, it undergoes several stages of manipulation until it reaches its final form.

After the guardrail profile is achieved, the machine can integrate additional processes such as punching holes or notching, which are essential for the installation of guardrails on highways. The entire process is automated and typically controlled by a computer program, which enhances precision and reduces labor costs.

Efficiency and Cost-Effectiveness

One of the standout features of highway steel guardrail roll forming machines is their efficiency. Traditional methods of guardrail manufacturing often involve labor-intensive processes that can lead to inconsistencies in product quality. In contrast, roll forming machines are designed to operate continuously, allowing for the rapid production of guardrails without compromising quality.

Moreover, the automation and precision offered by these machines result in reduced material waste. This is particularly beneficial in a time where sustainability is a growing concern in manufacturing industries. The ability to produce high volumes of guardrail sections quickly and with minimal waste provides a significant cost advantage, making it a preferred choice for manufacturers globally.

Quality and Durability

Guardrails manufactured using roll forming technology are subjected to stringent quality control measures to ensure they meet safety standards. High-quality materials, combined with advanced manufacturing techniques, result in products that are strong, durable, and capable of withstanding the elements. Galvanized steel guardrails, for instance, offer excellent resistance to rust and corrosion, prolonging their lifespan and reducing maintenance costs.

The specifications and designs produced by steel guardrail roll forming machines also adhere to international safety regulations, ensuring they effectively protect drivers and pedestrians by minimizing the chances of serious injury during accidents.

Conclusion

In summary, highway steel guardrail roll forming machines represent a significant advancement in the production of safety equipment for roads and highways. By leveraging the benefits of roll forming technology, manufacturers can produce high-quality, durable guardrails quickly and cost-effectively. As safety needs continue to evolve and the demand for road infrastructure grows worldwide, these machines will play an increasingly vital role in enhancing highway safety through efficient and innovative manufacturing solutions. The investment in modern roll forming technology not only supports the safety of road users but also contributes to the sustainable practices necessary for future manufacturing endeavors.