The Importance of Coil Metal Cut to Length Lines in Manufacturing

In today's fast-paced manufacturing environment, efficiency and precision are paramount. Among the various processes utilized in the fabrication of metal products, the coil metal cut to length line stands out as a crucial technology. This process not only enhances productivity but also ensures high-quality outputs that meet specific industry standards.

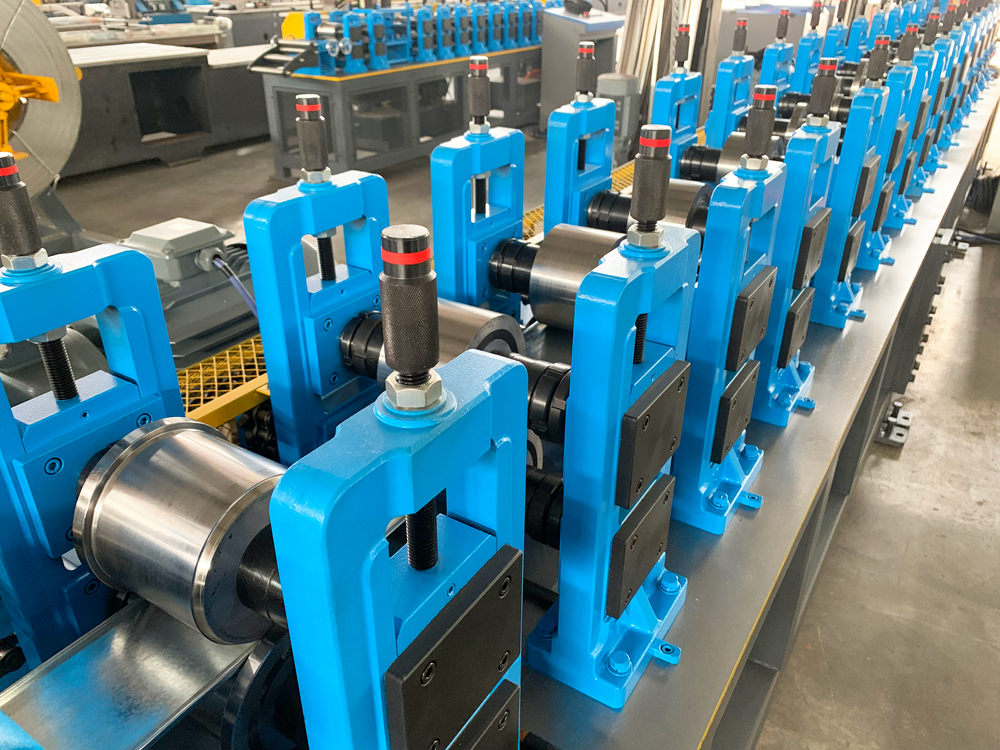

A coil metal cut to length line is designed to take large coils of metal—usually steel, aluminum, or other ferrous and non-ferrous materials—and cut them into predetermined lengths. This technology is particularly vital for industries that require exact specifications for their components, such as automotive, construction, and appliance manufacturing. The ability to deliver cut-to-length materials means that manufacturers can streamline their production processes, reduce waste, and ensure that they have the right material on hand for their assembly lines.

One of the primary advantages of using a coil metal cut to length line is its efficiency. Traditional methods of cutting metal often involve manual labor, which can be time-consuming and prone to human error. In contrast, automated cut to length systems dramatically increase production speeds. These systems can process coils quickly and accurately, allowing manufacturers to meet tight deadlines while maintaining consistency in product quality.

Another significant benefit is the reduction of material waste. Waste management is a critical concern in the manufacturing sector, with many companies striving to optimize their operations for both environmental and economic reasons. A coil metal cut to length line allows for precise cuts that maximize the use of raw materials. This not only reduces costs associated with wasted metal but also contributes to more sustainable manufacturing practices.

Moreover, advancements in technology have led to the development of sophisticated cut to length lines that incorporate features like digital controls, real-time monitoring, and automated stacking. These innovations enhance the overall performance of the lines, providing manufacturers with greater control over their production processes. The ability to program different cut lengths and specifications ensures flexibility, enabling manufacturers to quickly adapt to changing market demands and customer requirements.

Implementing a coil metal cut to length line also improves safety in the workplace. Automated systems reduce the need for manual handling of heavy coils, which can pose significant risks to workers. Enhanced safety features, such as protective barriers and emergency stop mechanisms, further contribute to a safer working environment.

In summary, coil metal cut to length lines play a pivotal role in modern manufacturing. By improving efficiency, reducing material waste, and enhancing workplace safety, these systems allow manufacturers to optimize their operations and meet the rigorous demands of today’s market. As industries continue to evolve, the importance of such cutting-edge technology will only grow, driving innovation and sustainability in metal fabrication.