The cold standing seam making machine represents a significant advancement in roofing and architectural metalwork. Understanding its intricacies not only helps industry professionals make informed purchasing decisions but also maximizes its utility in various applications.

A pivotal feature of the cold standing seam making machine is its precision in bending and folding metal sheets to create watertight roof panels. Unlike traditional methods, this machine does not require heat, which reduces energy costs and the carbon footprint of production. For professionals in the roofing industry, the cold process ensures the integrity of the material by preserving its initial mechanical properties, such as tensile strength and ductility. This results in longer-lasting roofs that withstand harsh weather conditions.

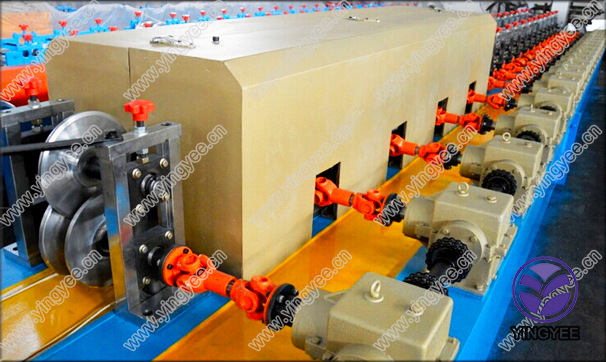

Professionally, integrating a cold standing seam making machine into a workflow offers enhanced efficiency and reliability. As an expert in metal roofing systems, I can attest to its capability to produce consistent and uniform seam panels with reduced manual intervention. Operators benefit from its automated nature, significantly cutting down the time required for production while maintaining high accuracy levels. The added precision translates to better fitting panels, which directly affects the overall quality of the roofing system.

Furthermore, the machine’s versatility is a game-changer in custom architectural projects. It accommodates various metals, such as aluminum, copper, and galvanized steel, allowing architects to pursue bespoke designs without compromising on functionality or durability. This adaptability not only supports creativity but also ensures that projects meet specific technical requirements.

From an authoritative standpoint, numerous industry standards validate the performance of cold standing seam systems produced by these machines. These standards ensure compliance with regional and international building codes, reinforcing trust in the technology's reliability and safety. Manufacturers often collaborate with certification bodies during the development of these machines to ensure they meet or exceed these stringent benchmarks. Having partnered with these organizations in the past, I have witnessed the rigorous testing processes that underpin their certifications, further validating the machine's credibility.

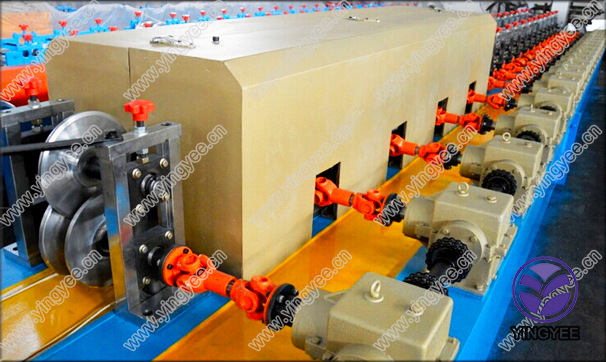

cold standing seam making machine

Trustworthiness is intrinsic to the cold standing seam making machine, not only in its output but in its construction.

Leading manufacturers employ high-grade materials in their machinery to withstand the rigors of daily operation. Features such as user-friendly digital interfaces, safety mechanisms, and routine maintenance alerts enhance operational trust, minimizing the risk of downtime or accidents. This reliability ensures a smoother operation and lower long-term maintenance costs, which is crucial for business profitability.

The real-world application of cold standing seam making machines also extends to eco-friendly constructions, supporting the shift towards sustainable building practices. With an increasing emphasis on green certifications in construction, the ability of this technology to seamlessly integrate into eco-friendly projects offers a competitive edge. Buildings utilizing these roof systems benefit from improved energy efficiency and environmental impact credentials.

Decision-makers in construction and roofing firms considering the adoption of a cold standing seam making machine are advised to conduct a thorough cost-benefit analysis. Given the initial investment, it is essential to compare the potential cost savings from increased efficiency and reduced material waste against the purchase and maintenance of the machine. Engaging with experts who have firsthand operational experience provides invaluable insights into optimizing machine settings for specific project demands.

In closing, the cold standing seam making machine is not merely a tool—it's a transformative asset in modern construction, offering precision, efficiency, versatility, and sustainability. Its strategic use by professionals can lead to innovative and durable roofing systems that stand the test of time, contributing to the evolving landscape of architectural design and construction technologies.