The Importance of Storage Upright Rack Forming Machines in Modern Warehousing

In an age where efficiency and space management are critical to the success of businesses, the role of storage systems cannot be overstated. One of the most innovative solutions to optimizing space in warehouses and storage facilities is the use of upright racks. These racks not only maximize floor space but also enhance the organization of inventory, allowing for easier access and management. At the heart of constructing these functional storage units lies the storage upright rack forming machine, a vital piece of equipment in modern manufacturing.

What is a Storage Upright Rack Forming Machine?

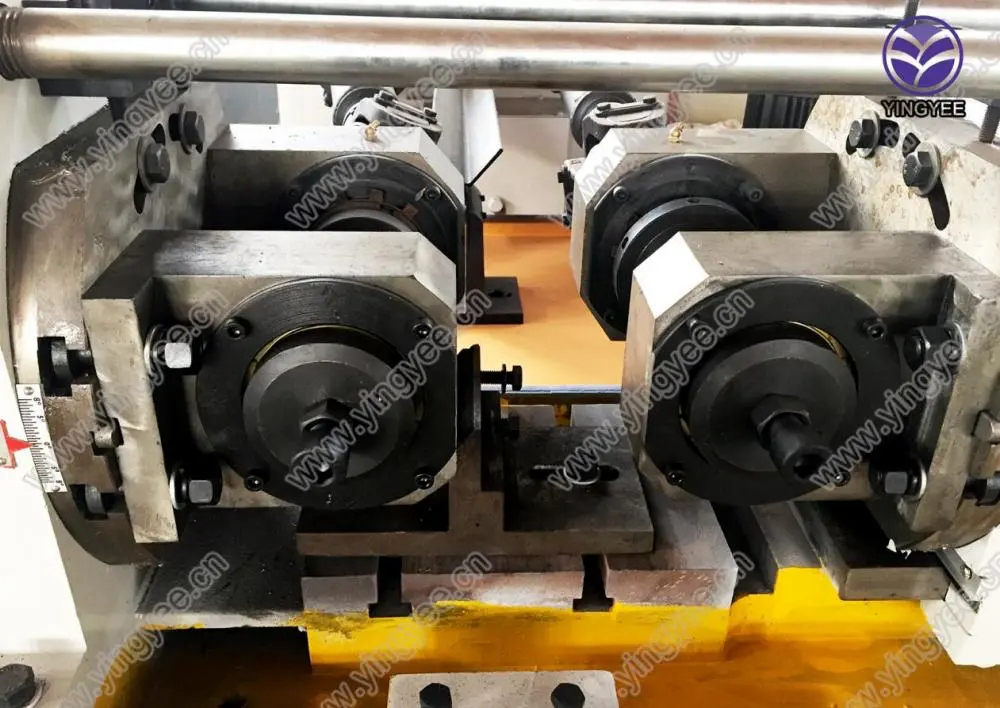

A storage upright rack forming machine is a sophisticated piece of machinery designed to fabricate components of upright racks used in warehousing. This machine employs advanced technology to process raw materials, particularly steel, into precisely engineered components, such as vertical beams and horizontal braces, which are the backbone of any rack system. The machine typically incorporates various processes such as cutting, bending, and welding, ensuring that each part meets strict specifications for strength and durability.

The Manufacturing Process

The production process begins with high-quality raw steel, which is fed into the machine. Using a combination of automated systems and skilled operators, the machine performs several functions that include

1. Cutting Steel sheets are cut into desired lengths using high-precision cutting tools to ensure accuracy. 2. Bending The cut pieces are then bent into specific angles and shapes, essential for creating the structural integrity of the upright racks. 3. Welding Parts are joined together using welding techniques that reinforce the strength of the rack components, ensuring they can withstand heavy loads.

4. Finishing The finished components are often coated or treated to prevent rust and improve aesthetics, preparing them for the final assembly stage.

This automated process not only speeds up production but also reduces labor costs and minimizes the chances of human error, resulting in high-quality rack components ready for assembly and installation

.Advantages of Using Storage Upright Rack Forming Machines

1. Efficiency These machines significantly streamline the production process, allowing manufacturers to meet demand quickly and efficiently. With the ability to produce a large number of components in a short time, businesses can keep up with the growing need for storage solutions.

2. Customization Modern upright rack forming machines can be programmed to create customized designs based on specific customer requirements. This flexibility enables businesses to cater to unique storage needs, maximizing warehouse space.

3. Quality Control Automated systems integrated within the machines ensure consistent quality across all produced components. This reliability is crucial for maintaining safety standards in high-load environments.

4. Cost-Effectiveness While the initial investment in a forming machine may be substantial, the long-term savings in labor, materials, and time can be significant. Additionally, the durability of produced racks reduces the frequency of replacements.

5. Sustainability Many manufacturers are now focusing on eco-friendly practices, and forming machines can contribute to this goal by optimizing material usage and minimizing waste during production.

The Future of Storage Solutions

As the logistics and warehousing industries continue to evolve, the demand for innovative storage solutions will only grow stronger. The storage upright rack forming machine plays a crucial role in meeting this demand, offering efficient, high-quality, and customizable solutions for businesses of all sizes.

Furthermore, advancements in technology, such as automation and artificial intelligence, are likely to enhance the capabilities of these machines, leading to even more sophisticated production processes in the future. This evolution will not only improve efficiency but also contribute to a sustainable approach in manufacturing, aligning with global trends toward environmental responsibility.

In conclusion, the storage upright rack forming machine is more than just a piece of equipment; it is a critical enabler of modern storage solutions. By investing in high-quality forming machines, manufacturers can ensure their products meet the demands of an ever-changing market, ultimately contributing to the success of warehouses and storage facilities around the world.