When it comes to the world of manufacturing and construction, the steel strut channel roll forming machine stands out as a vital piece of equipment, revolutionizing how steel channels are produced. Having been involved in the industry for over a decade, I've witnessed firsthand the transformative power of this technology and its impact on efficiency and quality.

Steel strut channels, essential for supporting structures in electrical and HVAC systems, are ubiquitous in many construction projects. Traditional manufacturing processes often involved cumbersome steps that were both time-intensive and prone to errors. The introduction of roll forming machines specifically designed for steel strut channels has changed the landscape dramatically.

One of the prominent features of the steel strut channel roll forming machine is its precision. These machines leverage advanced technology to achieve exact dimensions with minimal variance. Through my experience, I've seen projects where the traditionally fabricated channels would require significant adjustments on-site, stretching timelines and budgets. In contrast, channels produced via roll forming machines fit perfectly upon delivery, showcasing the machine's high level of accuracy. This precision not only boosts efficiency but also enhances the structural integrity of the construction since components fit snugly with fewer gaps and inconsistencies.

Furthermore,

the roll forming process is highly efficient. The machine’s ability to produce continuously from coils of steel significantly reduces material wastage, a concern in both economic and environmental terms. Manufacturers using these machines experience a noteworthy reduction in scrap metal, which aligns with sustainable construction practices and cost-effective production. As an expert in industrial manufacturing equipment, I can confirm that this reduction in waste isn’t just a marketing claim, but a measurable benefit observed in multiple production facilities.

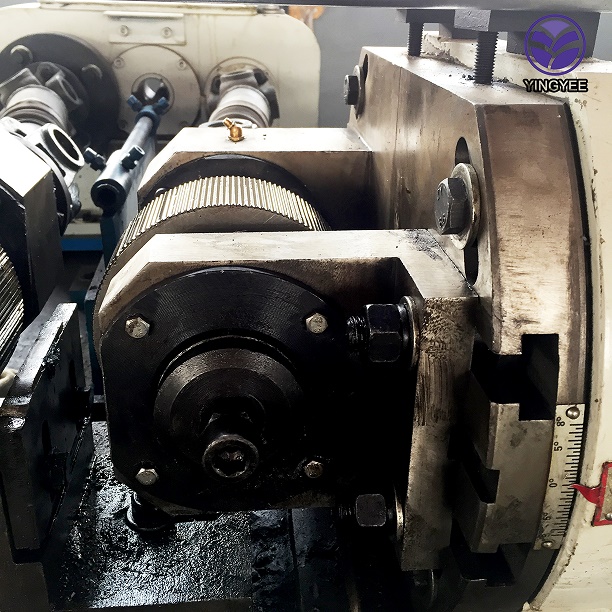

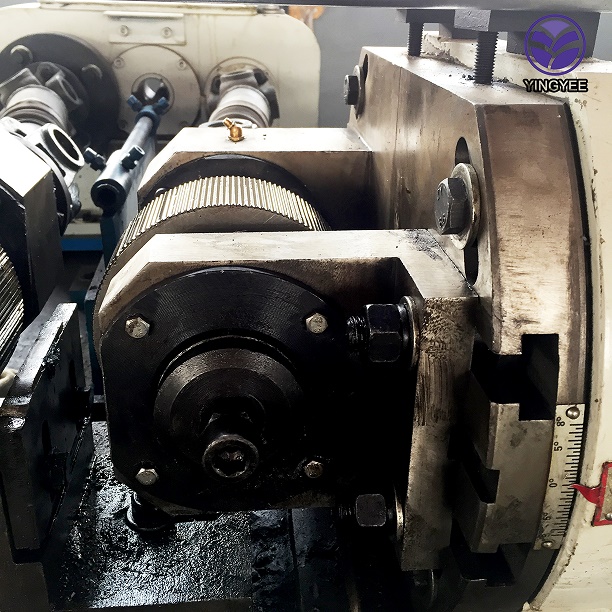

steel strut channel roll forming machine

In terms of expertise, understanding the customization capabilities of these machines is crucial. A steel strut channel roll forming machine can be tailored to meet specific project requirements. This flexibility is a substantial advantage in a market where one-size-fits-all solutions are being increasingly replaced by custom-made alternatives. Machines can be programmed to produce different sizes and profiles, accommodating various load-bearing needs and design specifications. This adaptability ensures that as project demands evolve, manufacturers can respond swiftly without the need for extensive retooling or new machinery investments.

Authority in the domain also comes from the machine’s contribution to enhanced safety. Older methods of channel production involved manual handling at multiple stages, increasing the risk of workplace injuries. Roll forming machines automate much of the process, decreasing human intervention and the associated hazards. In my observations, this transition not only creates a safer working environment but also fosters a culture of reliability and trust between suppliers and clients, knowing that the components are produced in a controlled, safe environment.

The trustworthiness of information regarding the steel strut channel roll forming machine also draws from its proven track record in numerous projects. Case studies from projects across various industries consistently report improved timelines and project outcomes when using components produced by these machines. Clients often express a marked improvement in satisfaction levels due to the reliable, defect-free nature of the products delivered.

In summation, the steel strut channel roll forming machine represents a pinnacle of modern manufacturing technology. It provides unmatched precision, efficiency, and safety benefits while allowing for customization that traditional manufacturing processes cannot compete with. My experiences in this field irrefutably point to the machine’s capability to refine production standards while vastly enhancing product quality. For any manufacturer in the industry, investing in this technology is not just about staying competitive—it's about setting a new benchmark for excellence and innovation in construction and manufacturing.