Understanding the Thick Coil Cut to Length Line A Comprehensive Overview

In the realm of manufacturing and metal processing, the thick coil cut to length line plays a pivotal role in enhancing efficiency and precision. As industries increasingly demand high-quality metal products, the importance of understanding this processing system becomes crucial for manufacturers seeking to optimize their production processes. This article explores the intricacies of the thick coil cut to length line, its components, functionality, and the benefits it brings to the manufacturing ecosystem.

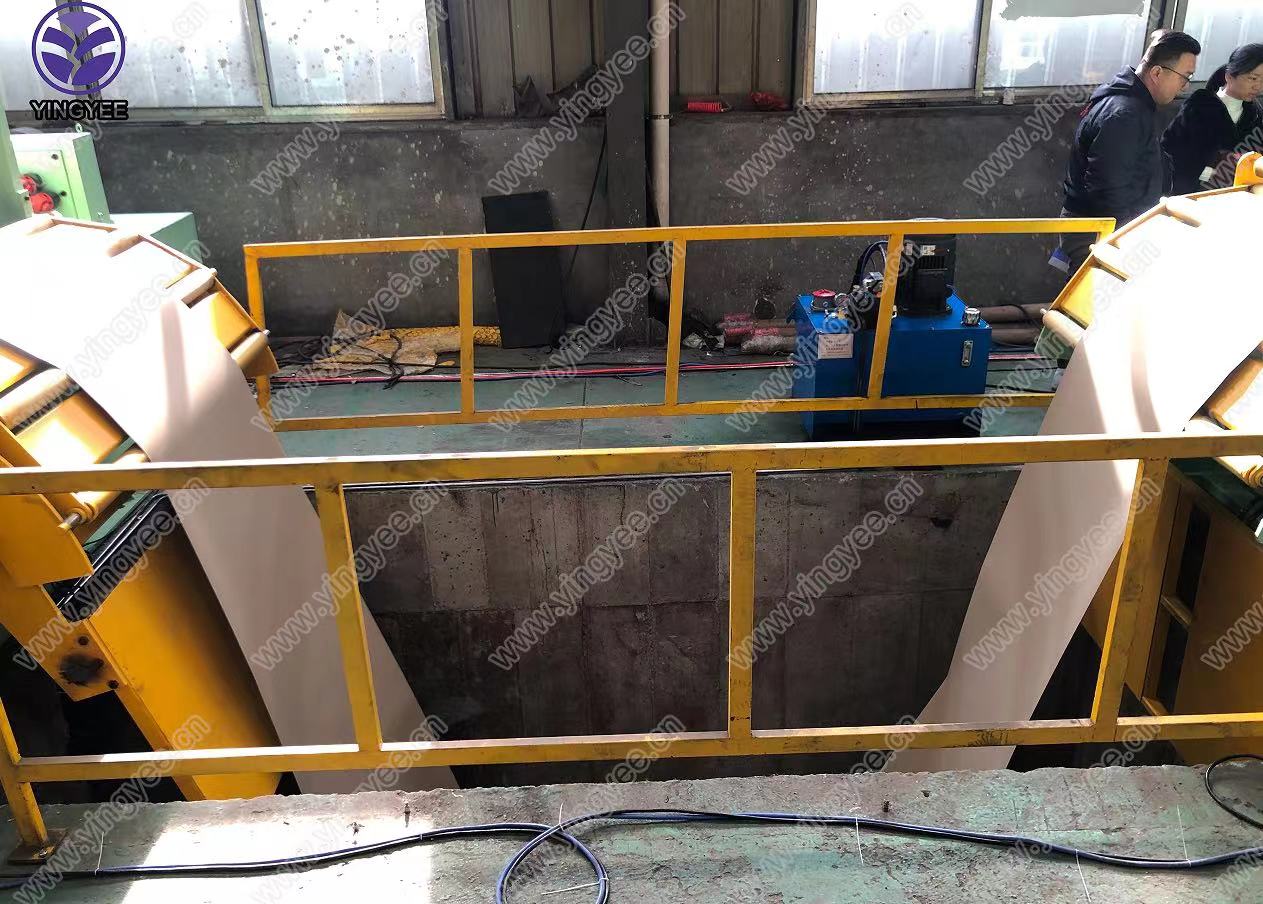

A cut to length line is a specialized piece of equipment designed to take large coils of metal, typically steel or aluminum, and cut them into specific lengths as per the requirements of downstream processes. The distinction of a thick coil cut to length line is primarily based on the thickness of the material it processes. Thick coils can range from a few millimeters to several centimeters, depending on the application. This line is essential for industries that require precise tolerances and specific dimensions for their metal sheets and plates.

Key Components of a Thick Coil Cut to Length Line

The thick coil cut to length line consists of several key components that work in unison to ensure smooth operation and high-quality output

1. Uncoiler The line begins with an uncoiler, where the thick coil is placed. This component is responsible for unwinding the coil and feeding it into the subsequent processing unit. A heavy-duty uncoiler is essential to handle the weight and thickness of the material safely.

2. Leveling System After the coil is unwound, the material is passed through a leveling system. This system is designed to remove any bends, twists, or imperfections in the coil, ensuring that the material is completely flat before cutting. This step is critical, as any defects in the coil can lead to inaccuracies in the final product.

3. Shearing Mechanism Once leveled, the coil moves onto the shearing mechanism, where it is cut to the specified lengths. Various cutting methods can be employed, including mechanical shears or laser cutting technologies. The precision of the cutting process directly impacts the overall quality of the products produced.

4. Stacker After the material has been cut, it is either stacked or bundled for further processing or delivery. The stacker organizes the freshly cut sheets or plates, ensuring they are easily accessible for loading or further handling.

5. Control System A sophisticated control system oversees the entire operation, allowing for the monitoring and adjustment of parameters such as feed speed, cutting length, and material thickness. This system improves accuracy and efficiency, minimizing waste and downtime.

Advantages of Using a Thick Coil Cut to Length Line

Investing in a thick coil cut to length line offers several advantages for manufacturers

1. Precision and Quality With advanced technologies for leveling and cutting, manufacturers can achieve high precision in dimensions, ensuring that products meet industry standards and customer specifications.

2. Reduced Waste By cutting coils to length with precision, the amount of scrap material is minimized. This efficiency not only saves costs but also contributes to more sustainable manufacturing practices.

3. Flexibility Thick coil cut to length lines can be configured to handle various materials and sizes, making them versatile for different applications within the metal processing industry.

4. Increased Production Speed Automation and streamlined processes significantly enhance production speed, allowing manufacturers to meet increasing demands without sacrificing quality.

5. Improved Safety Modern cut to length lines are designed with safety features, reducing the risk of accidents during operation. This focus on safety is critical in heavy-duty environments common in metal processing.

Conclusion

The thick coil cut to length line represents a vital component in modern manufacturing practices, particularly in industries demanding high-quality metal products. By understanding its components, functionality, and benefits, manufacturers can leverage this technology to enhance their production capabilities. As the industry continues to evolve, the significance of such advanced processing systems will undoubtedly grow, driving efficiency and quality in the manufacturing of metal products for years to come.