The Angle Iron Roll Forming Machine A Key Player in Metal Fabrication

In the realm of metal fabrication, the angle iron roll forming machine stands out as a pivotal piece of equipment, enabling the efficient production of angle iron, which is widely used in construction and manufacturing. This machine is specifically designed to take flat metal sheets and process them into angle iron configurations, characterized by a 90-degree angle in cross-section.

Understanding the Process

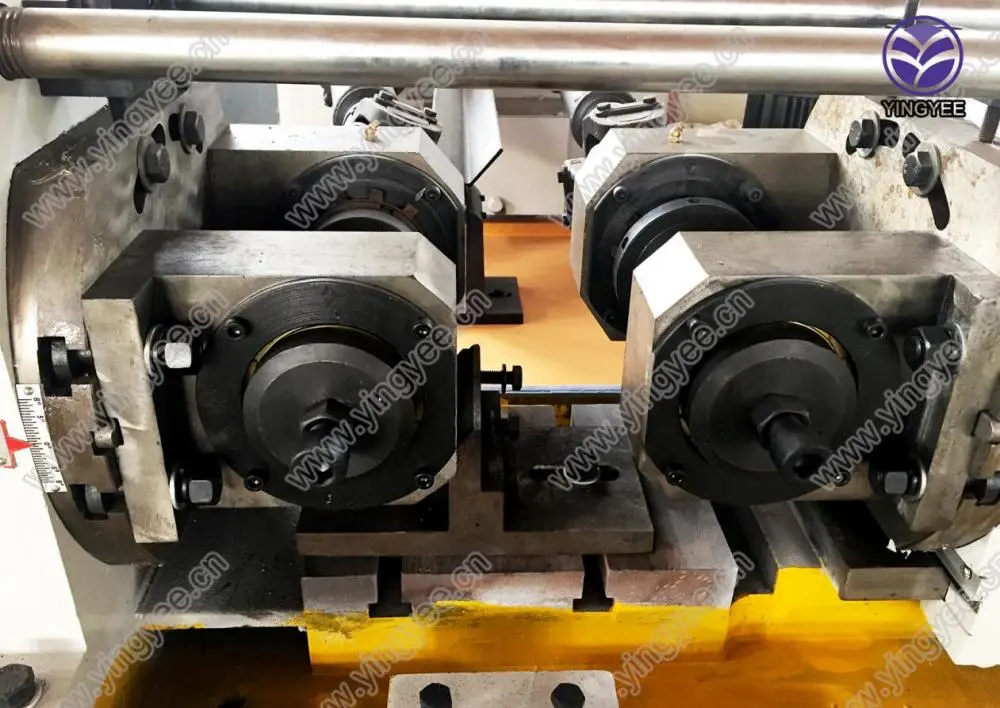

The operation of an angle iron roll forming machine involves several sequential steps. Initially, flat steel sheets or strips are fed into the machine. The roll forming process utilizes a series of rollers that progressively shape the metal into the desired angle. As the material passes through each roller station, it is gradually bent and formed until it reaches the final angle specifications.

One of the primary advantages of using a roll forming machine is its efficiency. Unlike traditional methods, which can be time-consuming and labor-intensive, roll forming allows for continuous production. This means that manufacturers can produce large quantities of angle iron in a shorter amount of time, thereby increasing productivity and reducing labor costs.

Key Features of Angle Iron Roll Forming Machines

Modern angle iron roll forming machines come equipped with advanced features that enhance their performance

. For instance, many machines are designed with programmable controls, allowing operators to adjust settings for different angle dimensions and materials easily. This flexibility is crucial for manufacturers who need to produce various types of angle iron for different applications.

Additionally, these machines often incorporate mechanized cutting systems that can swiftly trim the formed angle iron to specified lengths, eliminating the need for separate cutting processes. Some models also include quality monitoring systems that ensure the consistency and precision of the final product.

Applications in Various Industries

Angle iron is a staple material used across a variety of industries. In construction, it serves as a vital component in structural frameworks, providing support and stability. Manufacturers utilize angle iron for fabricating brackets, frames, and supports in machinery and equipment. Automotive industries also benefit from angle iron, where it’s used in vehicle frames and parts.

The versatility of angle iron means that the demand for these products is consistently high, which further solidifies the importance of angle iron roll forming machines in the manufacturing process.

Conclusion

In summary, angle iron roll forming machines are indispensable tools in the field of metal fabrication. Their ability to efficiently produce high-quality angle iron makes them crucial for meeting the demands of various industries, including construction and manufacturing. As technology advances, these machines are expected to evolve further, incorporating even more sophisticated features that enhance their performance and versatility. Investing in an angle iron roll forming machine not only streamlines production but also ensures that manufacturers can keep pace with the ever-increasing market demands for angle iron products.