The Evolution and Importance of Steel Pipe Making Machines

In the modern industrial landscape, steel pipes have become an essential component for various sectors, including construction, manufacturing, oil and gas, and infrastructure development. The production of these pipes is made efficient and effective through advanced steel pipe making machines. These machines, capable of producing high-quality steel pipes in large quantities, are a testament to the evolution of manufacturing technology.

The development of steel pipe making machines dates back to the late 19th century when the demand for steel infrastructure began to rise dramatically due to rapid industrialization. Initially, pipe production was a labor-intensive process, involving manual labor and rudimentary machinery. However, technological innovations led to the creation of more sophisticated equipment, which significantly increased the efficiency and quality of pipe manufacturing.

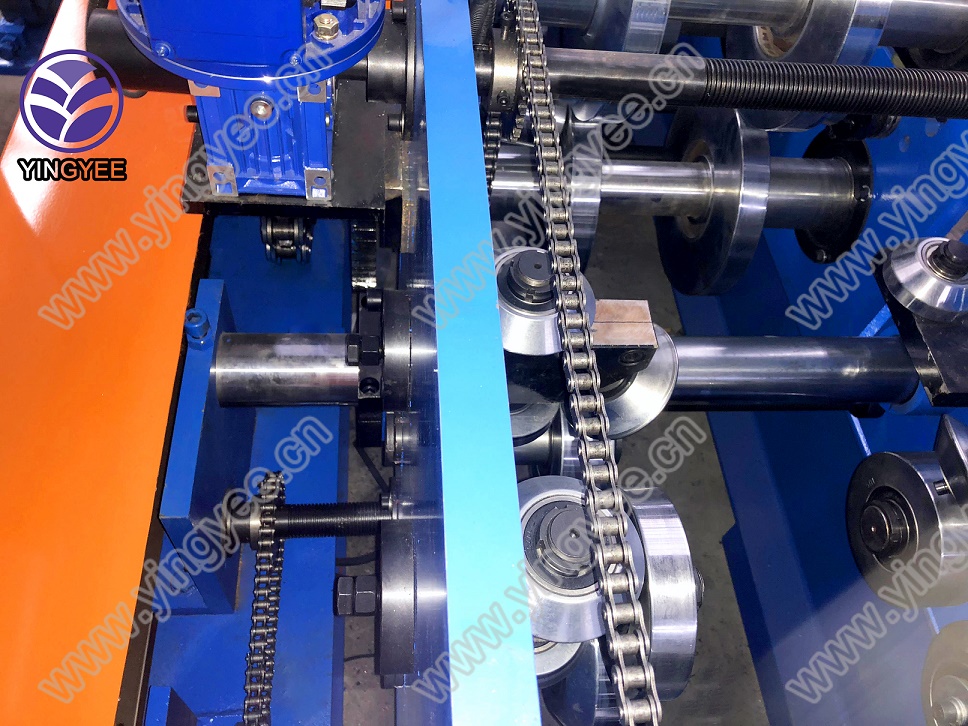

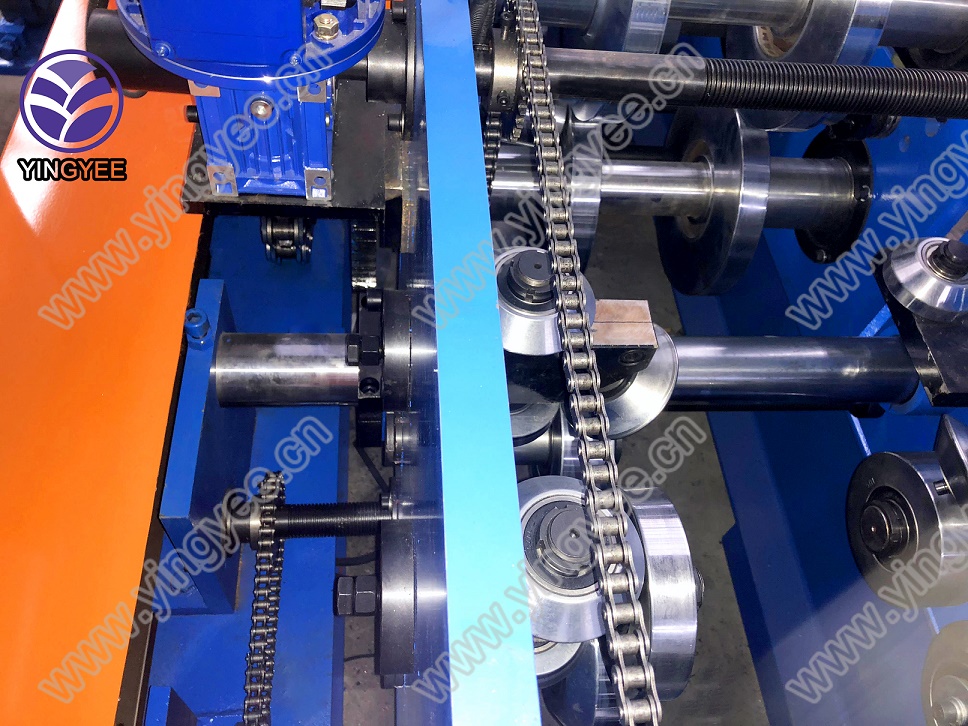

Today, steel pipe making machines incorporate advanced features such as automation, precision control, and high-speed production capabilities. These machines are typically composed of several key components strip shear, forming section, welding unit, sizing section, and cutting unit. The process commences with the unwinding of a flat steel strip, which is then sheared to the required length. The strip is subsequently shaped into a pipe profile using a series of rollers.

The welding unit plays a crucial role in the pipe production process. There are various welding techniques employed, including electric resistance welding (ERW) and submerged arc welding (SAW). Each method has its advantages—ERW is known for its efficiency and is commonly used for thinner wall pipes, while SAW is suited for larger diameter pipes with thicker walls, making it ideal for heavy-duty applications.

steel pipe making machine

Once formed and welded, the pipes move to the sizing section, where they are precisely shaped and any irregularities are corrected. This step ensures that the pipes meet industry specifications and are suitable for their intended applications. After sizing, the pipes are cut to the desired lengths. The cutting unit can be equipped with advanced technologies such as laser cutting or high-speed saws, facilitating precise and clean cuts.

The importance of steel pipe making machines extends beyond mere production efficiency. The quality of steel pipes produced can significantly impact the safety and reliability of infrastructure. For instance, in the oil and gas industry, high-quality pipes are essential for transporting crude oil and natural gas safely over long distances. Any failure in these systems can lead to catastrophic consequences, making the quality control processes within steel pipe manufacturing critical.

Moreover, as environmental concerns grow, the industry is shifting towards more sustainable practices. Steel pipe making machines are increasingly being designed to minimize waste, conserve energy, and use recycled materials. Innovations such as electric arc furnaces (EAF) for steel production and automated processes for monitoring emissions are part of this trend.

In conclusion, steel pipe making machines are a cornerstone of modern manufacturing processes. They have evolved rapidly over the years, driven by technological advancements and the increasing demand for high-quality steel pipes across various industries. As industries continue to grow and change, these machines will undoubtedly play a pivotal role in meeting the challenges of tomorrow while also promoting sustainability and efficiency. By investing in advanced steel pipe making machinery, manufacturers can ensure they remain competitive in an ever-evolving market, contributing to the development of vital infrastructure and supporting global economic growth.