Exploring the Steel Channel Machine A Necessity for Modern Fabrication

In the world of metal fabrication, efficiency, precision, and quality are paramount. Among the various types of machinery that facilitate these requirements, the steel channel machine stands out as a crucial tool for producing high-quality steel channels essential for construction, manufacturing, and various engineering applications.

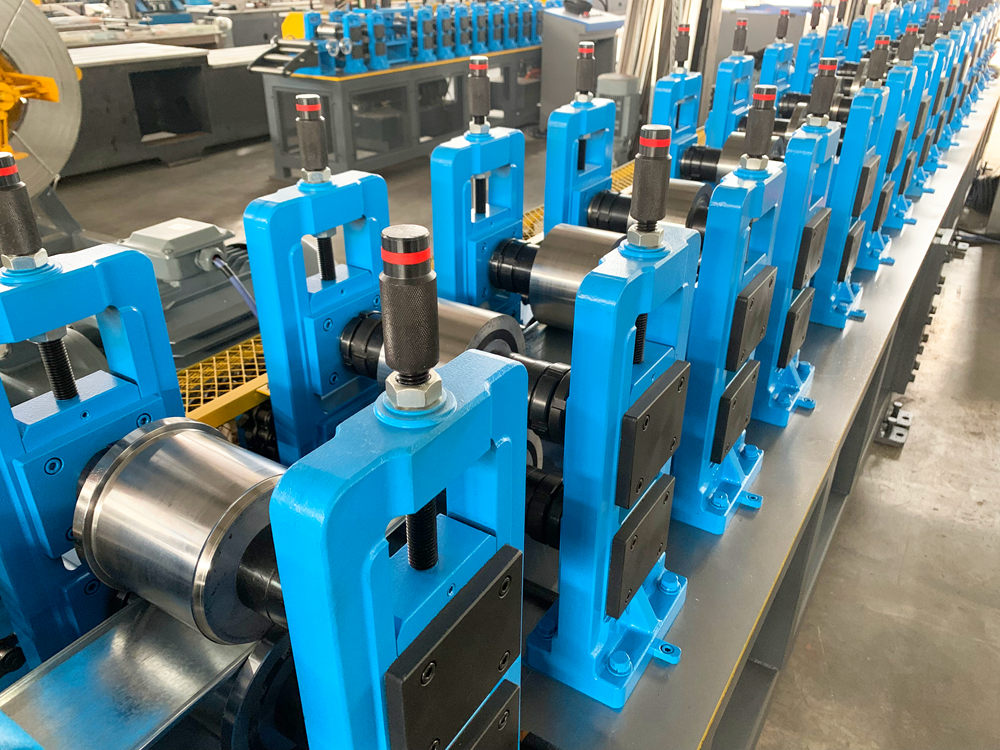

What is a Steel Channel Machine?

A steel channel machine is an industrial machine designed to produce steel channels, which are structural shapes characterized by a C-like cross-section. These channels, also known as C-channels, are commonly used in construction and manufacturing due to their versatility and structural integrity. The process of channel manufacturing involves several steps, including forming, cutting, and finishing the steel into accurate dimensions.

Types of Steel Channel Machines

Steel channel machines come in various configurations. Some of the most common types include

1. Cold Forming Machines These machines use the cold working process to shape steel sheets into channels. This method is preferred for producing lightweight but strong channels that do not require additional heating.

2. Hot Rolling Machines Hot rolling involves heating the steel above its recrystallization temperature and then passing it through rollers to form the channel shape. This process enhances the material’s ductility and allows for the production of larger channels.

3. Punching Machines For channels that require holes or special profiles, punching machines can integrate additional operations, such as punching holes or creating flanges, during the channel formation process.

4. Cutting Machines After the channels are formed, cutting machines ensure that they are trimmed to the desired lengths, which is critical for precision in construction projects.

Applications of Steel Channels

Steel channels produced by these machines have numerous applications across various industries

- Construction Steel channels are widely used in building frameworks, bridges, and supports due to their robustness and ability to bear heavy loads.

- Manufacturing They serve as essential components in machinery, conveyors, and equipment, where strength and stability are required.

- Automotive Industry Steel channels are integral to the manufacturing of vehicle frames and chassis, providing the necessary support and safety features in vehicles.

- Furniture and Design Modern furniture often utilizes steel channels for legs and support structures, thanks to their aesthetic appeal and strength

.

The Process of Channel Production

The production of steel channels typically involves several stages

1. Material Preparation High-quality steel sheets are selected based on their intended application.

2. Forming The sheets are fed into the channel machine, where they are rolled or formed into the desired shape.

3. Cutting The formed channels are then cut to specified lengths using advanced cutting technologies, ensuring accuracy.

4. Finishing Channels may undergo finishing processes such as welding, sanding, or coating to enhance their appearance and resistance to corrosion.

5. Quality Control Finally, each channel is subjected to rigorous quality control checks to ensure that they meet industry standards and specifications.

Advantages of Using Steel Channel Machines

Investing in a steel channel machine offers numerous advantages for manufacturers and fabricators

- Efficiency These machines streamline the production process, reducing labor costs and production time.

- Precision With advanced technologies, steel channel machines ensure consistent dimensions and high-quality output.

- Versatility They can adapt to various steel grades and sizes, making them suitable for different projects.

- Cost-Effectiveness Producing channels in-house can significantly reduce material costs in the long run.

Conclusion

As the demand for high-quality steel products continues to grow in various industries, the role of steel channel machines becomes increasingly vital. Their ability to produce reliable, strong, and precisely formed steel channels makes them a cornerstone of modern fabrication processes. By investing in this machinery, manufacturers can enhance their production capabilities, meet market demands, and ensure they remain competitive in a rapidly evolving industry. The steel channel machine is not just a tool; it is an essential part of the infrastructure that supports our modern world.