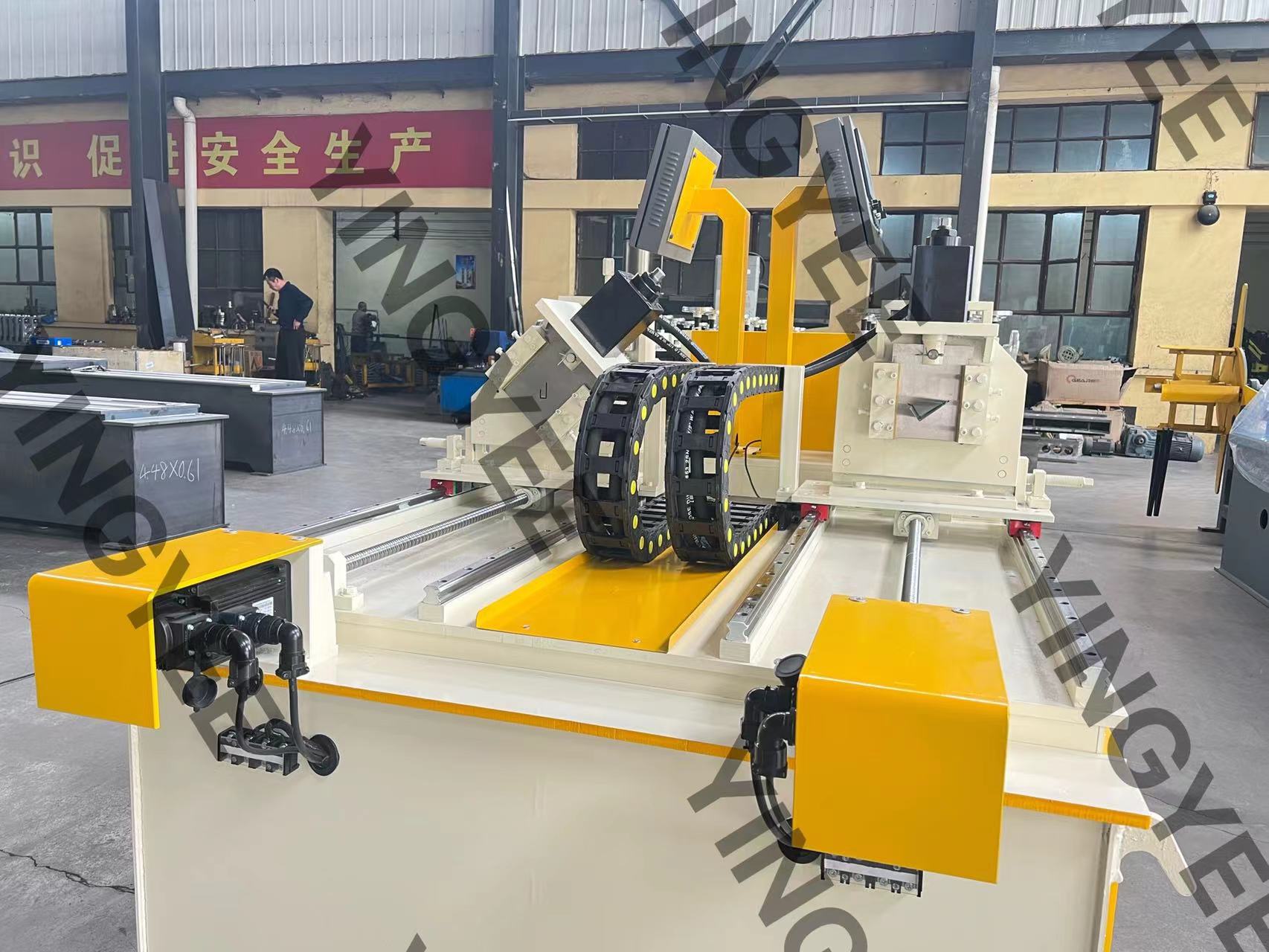

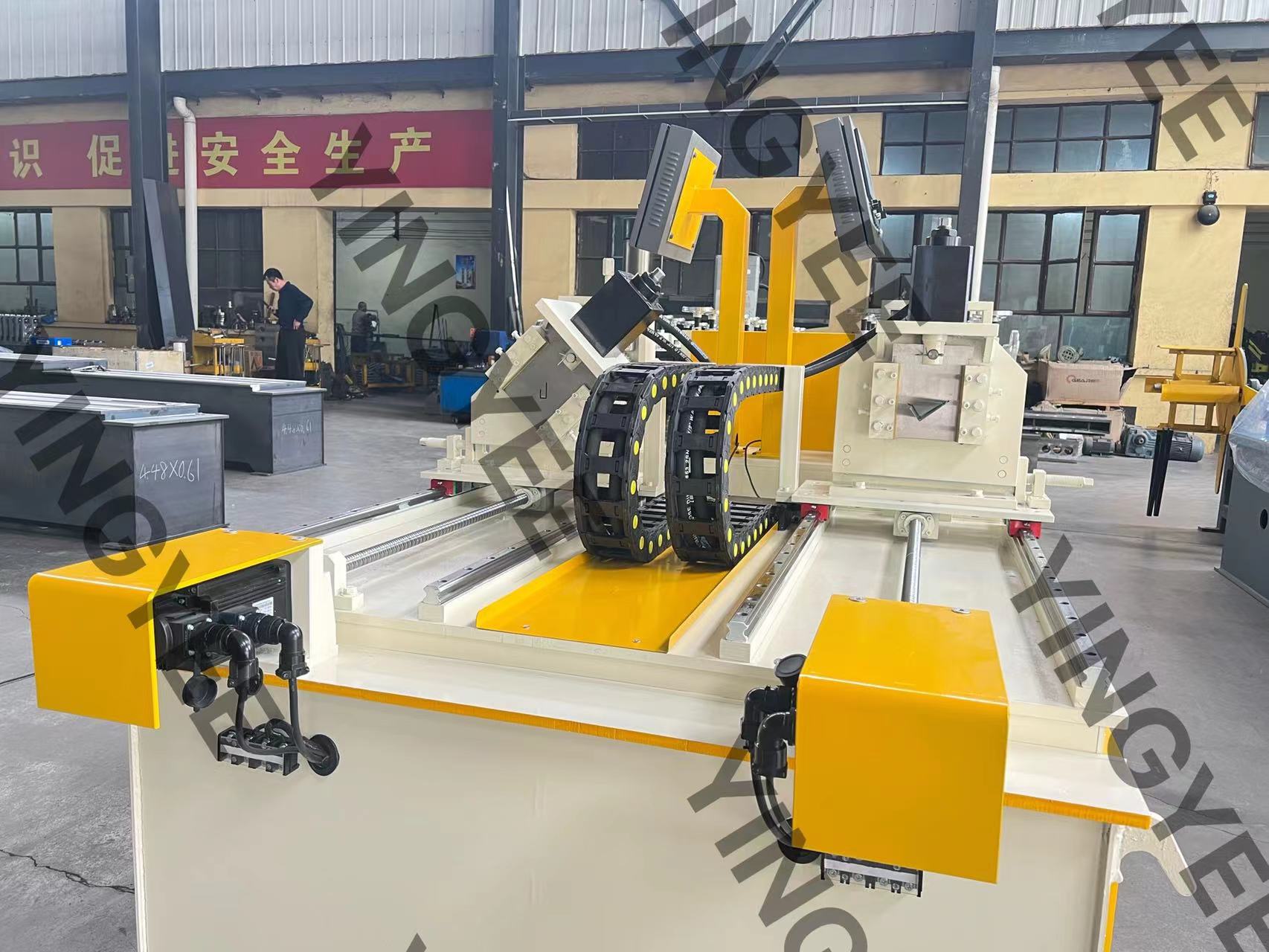

Exploring the world of industrial machinery can be an intricate endeavor, but when it comes to the rack upright roll forming machine, its significance in shelving and storage solutions cannot be overstated. This pivotal piece of equipment is the backbone of manufacturing processes that demand precision, durability, and consistency. For businesses aiming to optimize their storage systems, understanding the mechanics and benefits of a rack upright roll forming machine is crucial for making informed decisions.

A rack upright roll forming machine is a specialized tool designed to fabricate the vertical supports of storage racks. These uprights are essential for constructing reliable shelving systems used in warehouses, distribution centers, and even retail environments. The precision engineering behind these machines ensures that the uprights maintain uniformity, essential for structural integrity and compatibility with other system components.

Expertly crafted roll forming machines start with high-quality steel, which is fed through a series of roll sets. Each roll set gradually bends the steel into the desired shape without altering the material's thickness, a testament to the machine's precision. This process not only preserves the steel's structural strength but also allows the customization of the upright's size and profile according to specific requirements.

Experience in the field dictates that when procuring a rack upright roll forming machine, attention should be paid to the equipment’s flexibility in handling various designs. Versatile machines enhance operational efficiency, allowing manufacturers to adapt to evolving storage solutions without needing extensive retooling. Over the years, industry veterans have noted that investing in machinery with advanced control systems enhances precision, reduces downtime, and minimizes waste.

Expertise in this domain points to the importance of a seamless integration of technology and design in these machines. Modern rack upright roll forming machines often feature programmable logic controllers (PLCs) which allow operators to set precise parameters and ensure consistent output. Additionally, integrating computer-aided design (CAD) and computer-aided manufacturing (CAM) capabilities allows for direct execution of complex design specifications, eliminating potential for human error and enhancing overall productivity.

rack upright roll forming machine

Furthermore, authoritativeness in selecting the right machine also involves considering the manufacturer's track record. Reputable manufacturers are known for their commitment to quality and innovation, providing machines that not only meet but exceed industry standards. Engaging with manufacturers who offer comprehensive training and support services can significantly enhance the operational lifespan of the machinery and ensure that personnel are well-versed in maximizing its capabilities.

Building trustworthiness in this domain extends beyond machine performance; it involves ensuring compliance with industry regulations and standards. Machines that adhere to strict quality and safety certifications often provide peace of mind that the operations will not face unexpected disruptions. Trust is also built through warranties and service contracts that demonstrate a manufacturer’s confidence in their product’s longevity and performance.

An often overlooked, yet critical aspect of rack upright roll forming machines is the maintenance regimen. Proper, routine maintenance is pivotal in sustaining operational efficiency and prolonging the machine’s lifecycle. Experience suggests that having a detailed maintenance plan tailored to the specific needs of the machine can prevent costly repairs and production downtime.

While technical prowess is vital in operating a rack upright roll forming machine, it’s the blend of technological advantages and human acumen that truly unlocks its potential. Equipping teams with hands-on training not only fosters a safe working environment but also encourages innovative problem-solving, enabling them to troubleshoot and optimize operations in real-time.

In conclusion, a rack upright roll forming machine is an indispensable asset for any enterprise committed to advancing its storage solutions. By investing in a machine that exemplifies excellence in experience, expertise, authoritativeness, and trustworthiness, a business not only enhances its own operational capabilities but also ensures sustainable growth in a competitive market. As this industry continues to evolve, those who remain at the forefront of technological and engineering innovations will find themselves best equipped to adapt and lead.