The evolution of construction technologies has paved the way for innovative machinery that bolsters efficiency and structural integrity. Among these advancements, the purlin roll forming machine for C/Z 100-300mm stands out, revolutionizing the process of creating robust and versatile purlins used in modern construction frameworks.

Purlins are crucial components in building structures, acting as horizontal supports for roof loads and offering stability. Traditionally, these were manufactured through more manual, less efficient processes that left room for inaccuracies and potential structural weaknesses. However,

the introduction of the C/Z 100-300mm purlin roll forming machine has transformed this landscape dramatically.

This machine's notable ability to switch seamlessly between C and Z profiles without requiring extensive tooling changes stands as a testament to its innovation. This flexibility is not merely a bonus but a necessity in today’s diverse construction projects, which often require quick adaptability to different structural designs. By accommodating a width range of 100 to 300mm, the machine caters to varied project demands, making it indispensable for construction firms looking to optimize their workflow.

The expertise embedded in the design of this machinery showcases engineering excellence. Built with precision, it guarantees the formation of high-quality purlins that adhere to stringent industry standards. For construction managers and engineers, the reliability of these machines translates to increased trust and reduced time in project planning phases, facilitating more accurate cost estimations and resource allocation.

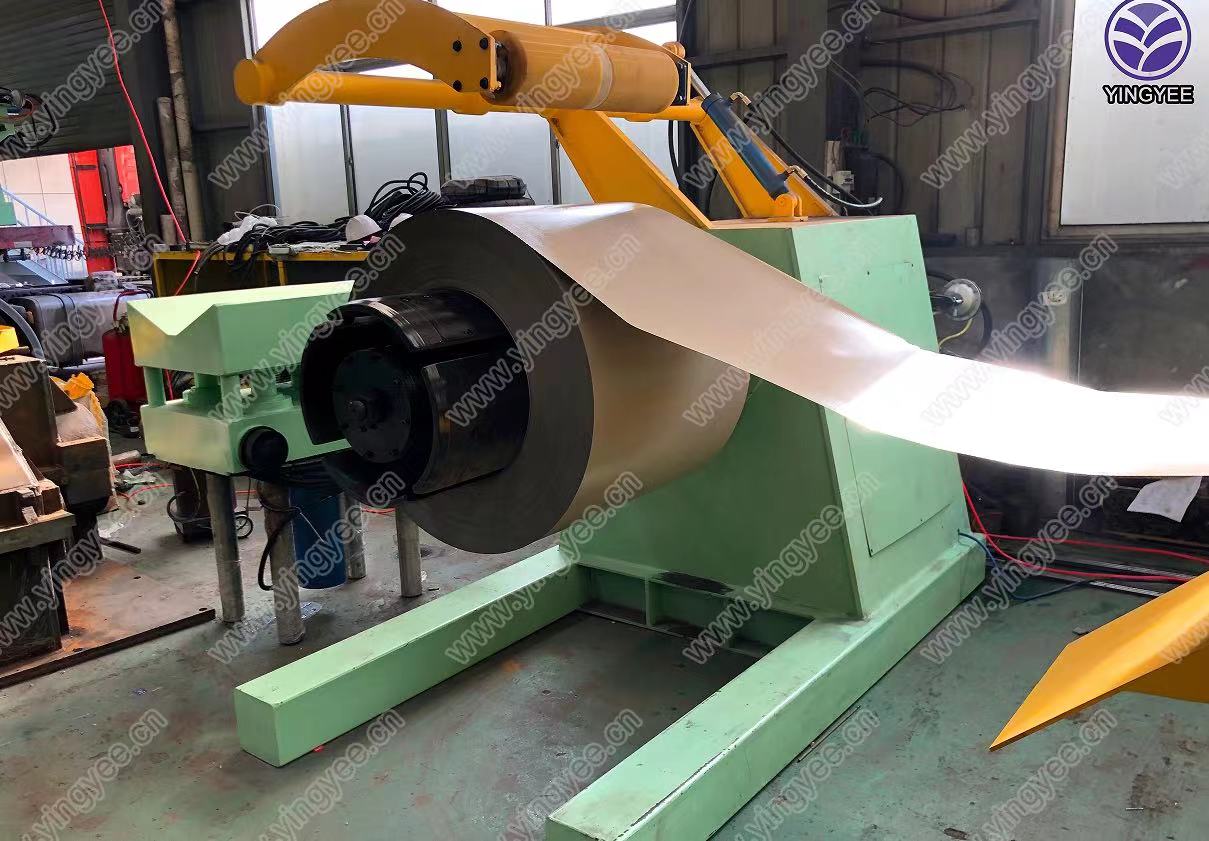

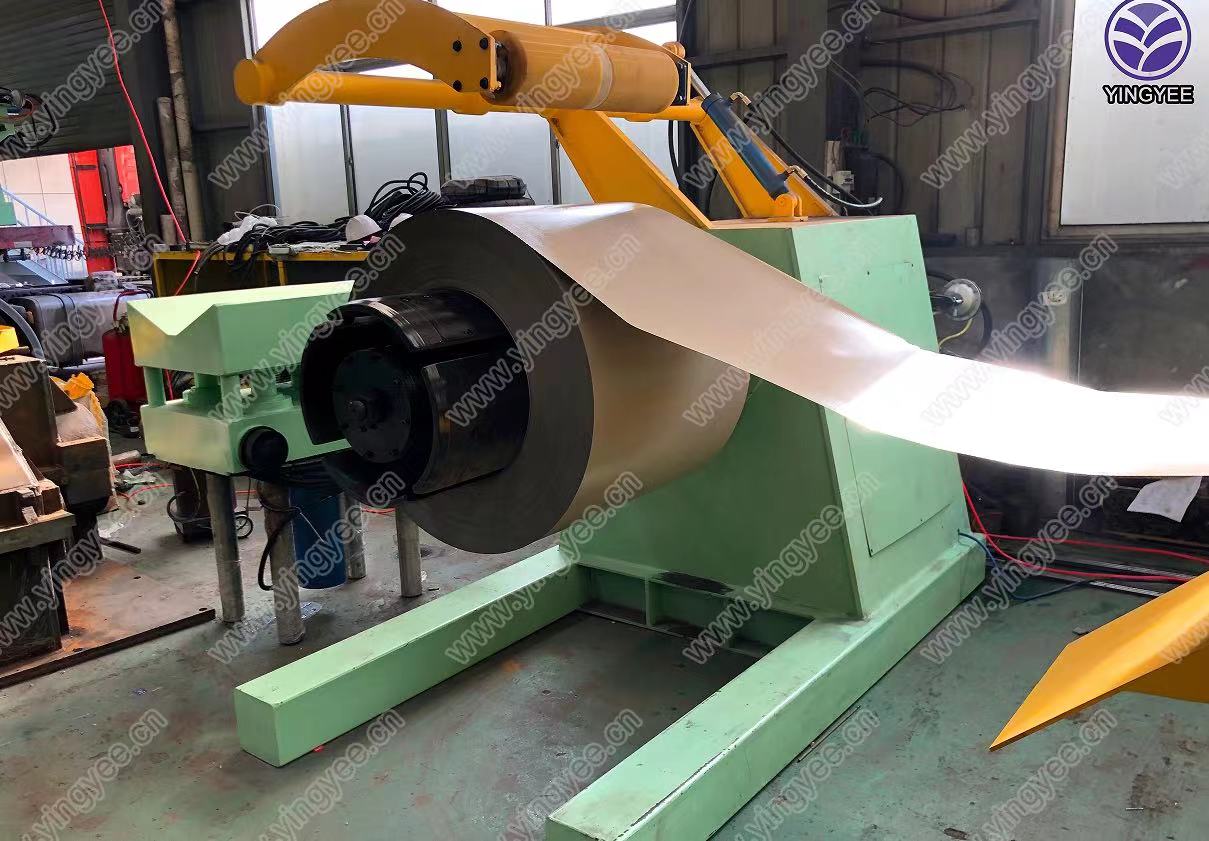

purlin roll forming machine for c/z 100-300mm

Experience with these roll forming machines reveals their suitability for both small-scale constructions and large industrial projects. Users have reported significant savings in both time and manual labor, thanks to the machine’s automated processes. Notably, this equipment's user-friendly interface ensures that operators, regardless of their experience level, can handle it with minimal training, reducing downtime and initial implementation costs.

Additionally, the authority of manufacturers producing C/Z 100-300mm purlin roll forming machines is well recognized within the industrial community. These manufacturers maintain a reputation for consistently delivering equipment that fulfills the rigorous demands of modern building codes and safety regulations. Purchasing from established brands ensures access to continued technical support and reliable after-sales service, which is crucial for maintaining operational continuity.

The trustworthiness of this technology is further exemplified in the tangible benefits observed in completed structures using machined purlins. These structures demonstrate enhanced durability and resistance to environmental stressors, providing peace of mind to both constructors and end-users. As a result, the long-term cost savings in maintenance and repairs contribute to the machine's attractiveness as a critical investment in sustainable construction practices.

In conclusion, the purlin roll forming machine for C/Z 100-300mm is more than just a piece of equipment; it is a cornerstone in the evolution of modern construction methodologies. Its implementation not only elevates the quality and efficiency of purlin manufacturing but also significantly impacts the overall success and reliability of building projects. Embracing this technology ensures that construction firms remain competitive, adaptable, and aligned with the growing demands of the industry.