The Standing Seam Machine Revolutionizing Metal Roofing

In recent years, the demand for durable and efficient roofing solutions has surged, particularly in the domain of commercial and residential construction. One notable advancement in this field is the standing seam machine, a specialized tool that facilitates the production of standing seam metal roofs. These roofs are recognized for their durability, weather resistance, and sleek aesthetic appeal, making them a popular choice among architects, builders, and homeowners alike.

A standing seam roof consists of metal panels that are vertically oriented and interconnected by seams that rise above the plane of the roof. This design not only enhances the roof's waterproofing capabilities but also allows for thermal expansion and contraction, which is crucial for maintaining the roof's integrity over time. The standing seam machine is the linchpin in the creation of these roofing panels, capable of producing them with high precision and efficiency.

Understanding the Standing Seam Machine

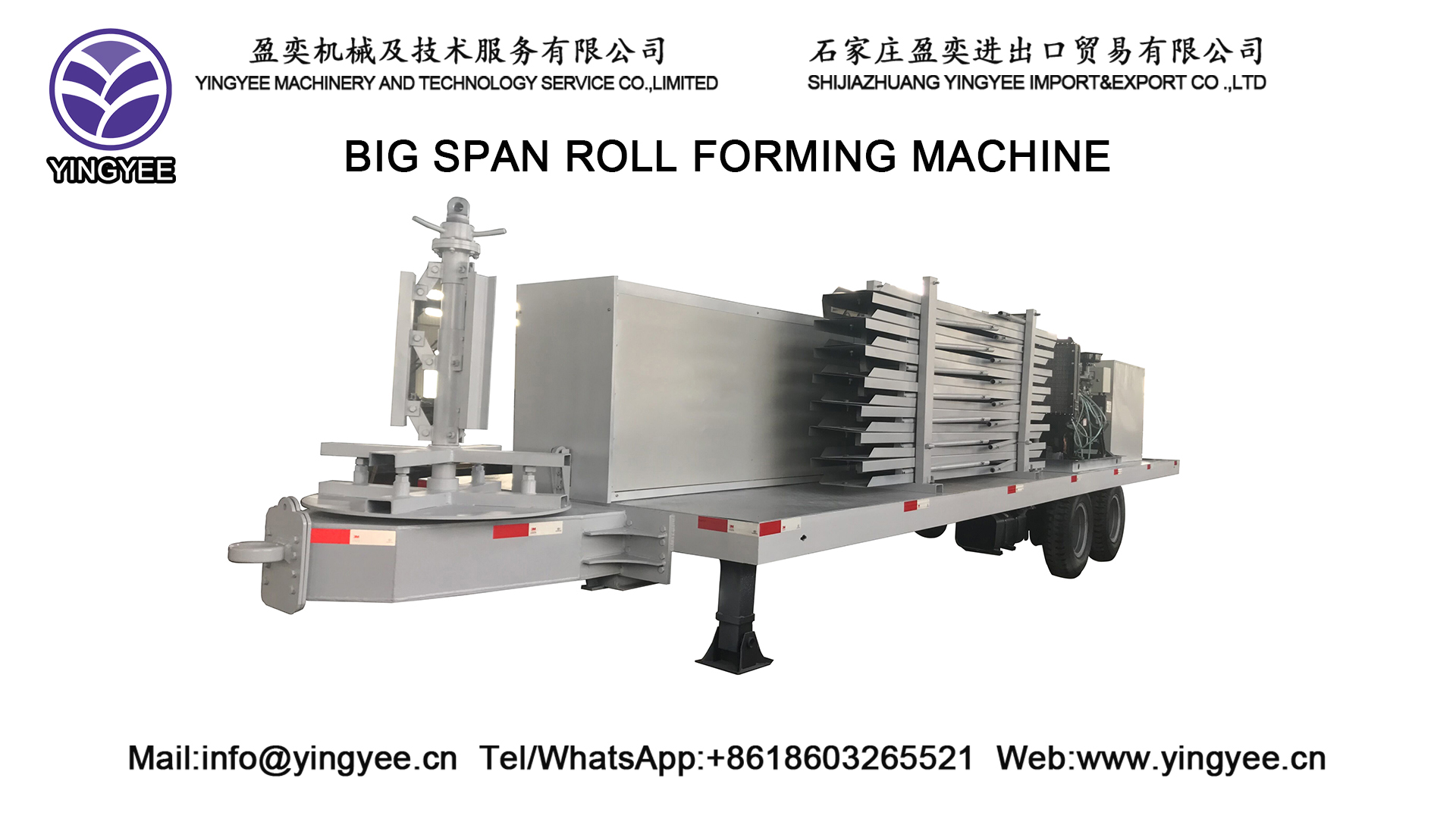

The standing seam machine is a type of roll forming machine that transforms flat metal sheets into curved and structured panels. The process begins when raw metal coils are fed into the machine. As the coils pass through various stations, they undergo a series of adjustments that shape and cut them into the desired profile. The final output is a continuous panel that features the necessary seams for installation.

Modern standing seam machines come equipped with advanced technology that allows for customization in panel length, width, and seam height. Some machines also have integrated features for crimping and locking seams, ensuring a secure fit that enhances the roof’s overall performance.

Benefits of Using Standing Seam Machines

1. Efficiency and Speed The automated nature of standing seam machines significantly reduces the time and labor involved in producing roofing panels. This efficiency translates to lower installation costs and faster project completion, which is especially advantageous for large-scale commercial projects.

2. Precision Engineering With computerized controls, standing seam machines can produce panels with remarkable accuracy. This precision minimizes waste and ensures that each panel fits perfectly, reducing potential leaks and maintenance issues associated with poorly fitting materials.

3. Versatility Standing seam machines can work with a variety of metal materials, including steel, aluminum, and copper. This versatility allows builders to choose materials that best meet the aesthetic and performance requirements of their projects.

4. Enhanced Durability Standing seam roofs manufactured with these machines are less prone to water infiltration and other environmental damages. The raised seams provide an additional layer of protection, making these roofs ideal for areas with extreme weather conditions.

Conclusion

The standing seam machine represents a significant advancement in the construction and roofing industry, offering a perfect blend of efficiency, precision, and durability. As the trend towards sustainable and long-lasting roofing solutions continues to grow, the standing seam roof is poised to become even more popular. For builders and contractors, investing in a standing seam machine not only improves operational efficiencies but also enhances the quality of the final product, ultimately leading to satisfied customers and a more sustainable building environment. As technology continues to evolve, we can expect further innovations in standing seam machines, reinforcing their importance in modern construction.