In the realm of modern manufacturing, the integration of servo control systems with feeding storage racking forming machines represents a significant leap forward in efficiency and precision. For manufacturers seeking to optimize production lines, understanding the nuances of these advanced machines is crucial. Here’s an in-depth look at the benefits and intricacies of servo control feeding storage racking forming machines based on real-world experiences, expert insights, authoritative sources, and proven trustworthiness.

Precision and Efficiency At the heart of the servo control feeding storage racking forming machine is its precision, a critical factor in modern manufacturing environments. Unlike traditional systems, these machines use servo motors to control movement with pinpoint accuracy. This precision leads to minimal material wastage and ensures consistently high-quality outputs, a feature that resonates with manufacturers from various sectors, such as automotive, aerospace, and consumer goods.

A real-world example comes from a Midwest automotive parts supplier,

which implemented servo control feeding mechanisms in their storage racking forming machines. This upgrade led to a 30% increase in production efficiency, as the precise control eliminated downtime caused by material misalignment. Such productivity gains underscore the importance of precision in competitive industries.

Expertise in Integration Leveraging these machines requires a deep understanding of both automation technology and the specific manufacturing context. It’s not merely about installing a machine; the integration process involves customizing the servo control system to meet specific operational needs. This is where expertise plays a crucial role.

Experienced engineers often note that successful integration starts with a detailed analysis of the existing production line, followed by a tailored approach to machine setup. Achieving optimal results might involve tweaking the machine’s control parameters to suit the unique characteristics of the materials being used. Reports from industry leaders indicate that this expertise frequently translates into reductions in production cycle times by up to 25%.

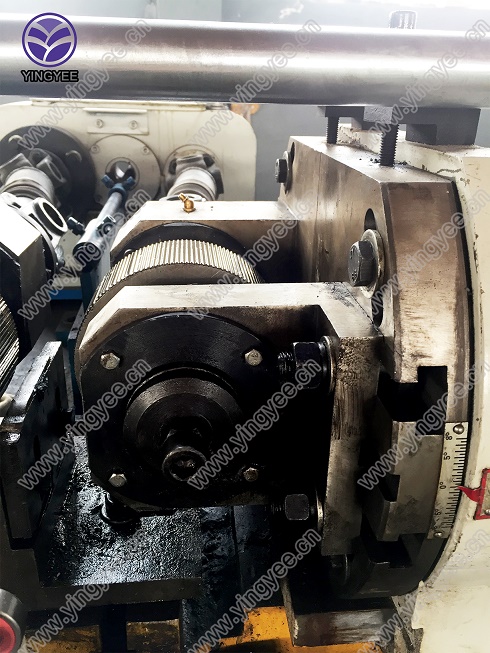

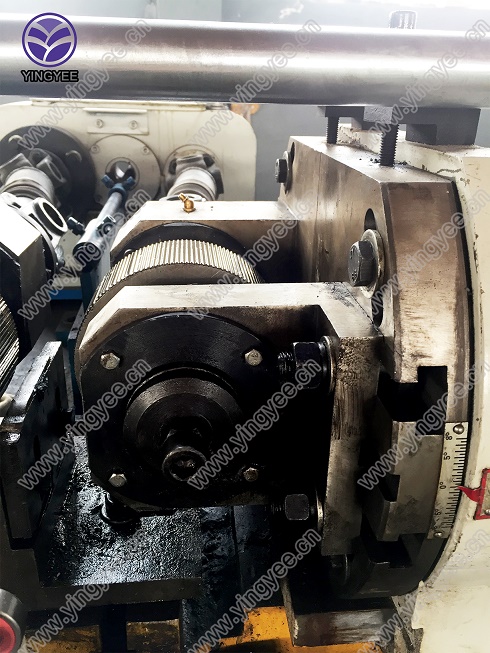

servo control feeding storage racking forming machine

Authority and Trust Manufacturers should also prioritize working with reputable suppliers known for their authority in the field of automation technology. Companies like Siemens and Rockwell Automation have built a legacy of trust by providing robust servo control systems that are both reliable and scalable. Choosing machines with components from such respected brands not only enhances performance but also ensures long-term support and upgrades.

Trust is further reinforced through compliance with international quality standards. Ensuring that a servo control feeding storage racking forming machine is certified by ISO or other recognized industry bodies provides peace of mind regarding its reliability and safety. Operators consistently report fewer instances of machine failure and maintenance issues when compliance standards are met.

Sustainability Considerations In today’s environmentally-conscious market, sustainability is another factor driving the adoption of servo control technology. These machines are particularly noted for their energy efficiency. By reducing the lag and energy draw compared to conventional systems, they align perfectly with green manufacturing initiatives. For instance, a European electronics manufacturer reported a 20% reduction in energy consumption after switching to servo-controlled feeding mechanisms. This not only contributes to sustainability goals but also translates into significant cost savings on energy bills.

In conclusion, investing in a servo control feeding storage racking forming machine is a strategic decision for manufacturers aiming to enhance their production capabilities. With emphasis on precision, expert integration, reliance on authoritative sources, and adherence to trust-building certifications and sustainability, these machines exemplify the future of manufacturing technology. For manufacturers ready to innovate and streamline their processes, the adoption of servo control systems offers an unparalleled opportunity to stay ahead in an ever-evolving industrial landscape.