Understanding Roller Door Roll Forming Machines

Roller door roll forming machines have become essential equipment in the manufacturing of roller doors, which are widely used in various commercial and residential applications. These machines are designed to produce high-quality metal profiles with precision and efficiency, making them a popular choice for manufacturers looking to streamline production processes.

What is a Roller Door Roll Forming Machine?

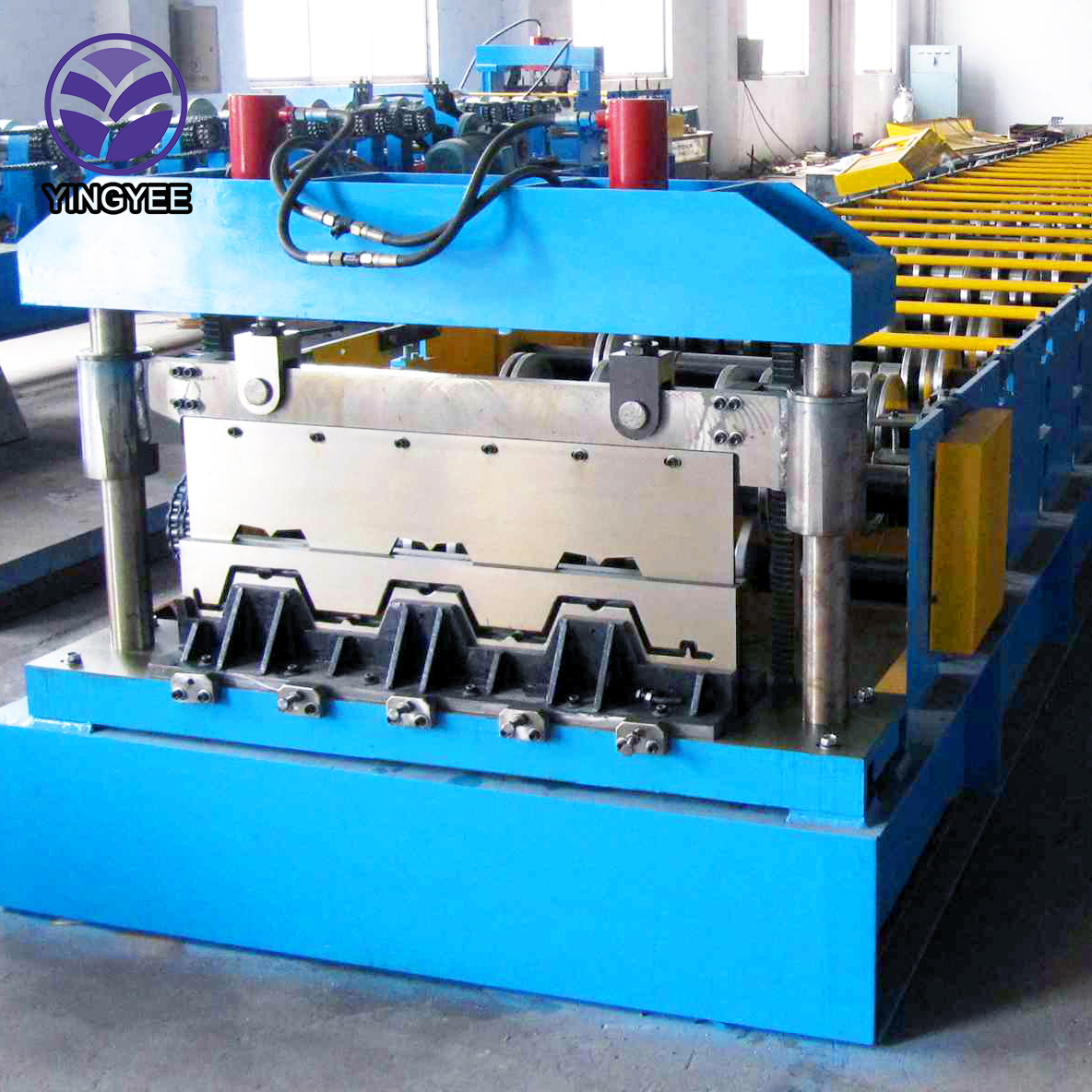

A roller door roll forming machine is a specialized piece of equipment that continuously forms metal sheets into specific profiles needed for roller doors. These machines typically use galvanized steel, aluminum, or other metal materials, which are fed into the machine where they undergo a series of bending and shaping processes. The resulting product is a strong, durable door that can withstand the rigors of daily use.

How Does it Work?

The operation of a roller door roll forming machine involves several key stages. First, metal sheets are fed into the machine's entry section, where they are aligned and prepared for forming. The metal is then passed through a series of rollers that progressively shape it into the desired profile. This process is often automated, ensuring that the production speed is optimal while maintaining consistent quality.

The rolls used in these machines are carefully designed to create specific profiles that meet industry standards as well as customer requirements. The rollers shape the metal into various configurations, which can include grooved patterns or other design elements that enhance functionality and aesthetics.

Once the metal has been formed into the desired shape, it often goes through cutting processes. A cut-off mechanism is usually employed to ensure that the lengths of the roller door sections are precisely measured and cut according to specifications. Many modern machines also incorporate controls for ease of operation, allowing manufacturers to adjust settings quickly for different production runs.

Advantages of Using Roller Door Roll Forming Machines

1. Efficiency One of the primary benefits of using a roller door roll forming machine is the increased efficiency in production. These machines can produce long lengths of roller door profiles continuously, significantly reducing the time required to manufacture doors compared to traditional methods.

2. Precision The automated nature of roll forming machines ensures high precision and repeatability in the production process. This leads to less waste and more uniform products, which are crucial for maintaining quality standards.

3. Customization Roller door roll forming machines can be designed to accommodate various metal thicknesses and profiles, allowing manufacturers to customize products based on specific customer requirements. Whether it’s a standard roller door or a specialized design, these machines can adjust to meet different needs.

4. Durability Doors formed using these machines are often stronger because of the cold-formed manufacturing process. The metal retains its structural integrity, resulting in a finished product that is not only aesthetically pleasing but also highly durable.

5. Reduced Labor Costs With modernization and automation integrated into the design of these machines, the need for manual labor is significantly reduced. This not only lowers labor costs but also reduces the chances of human error.

Conclusion

The roller door roll forming machine is a cornerstone of modern manufacturing for roller doors. Its ability to produce high-quality, customized profiles efficiently has made it a valuable asset in the industry. As technology continues to evolve, we can expect further improvements in speed, efficiency, and versatility of these machines, ushering in a new era of manufacturing excellence in door production. For manufacturers committed to quality and efficiency, investing in a roller door roll forming machine is an opportunity that promises substantial returns.