The Ridge Cap Tile Roll Forming Machine A Cutting-Edge Solution for Roofing Systems

In the world of modern construction, efficiency and durability are paramount. Roofing systems, in particular, require materials that not only provide protection against the elements but also enhance the aesthetic appeal of a structure. One of the most innovative tools in the roofing materials sector is the Ridge Cap Tile Roll Forming Machine. This advanced piece of machinery enables the production of high-quality ridge cap tiles, which are essential for completing pitched roofs.

Understanding Ridge Caps

Ridge caps are the finishing elements placed at the top of pitched roofs. They serve multiple purposes they protect the roof structure from water penetration, create a seamless appearance, and enhance the overall look of the building. Typically made from materials like metal, ceramics, or plastics, ridge caps must withstand harsh weather conditions while maintaining their functionality and appearance over time. Given their critical role, the manufacturing process of ridge caps must prioritize accuracy, quality, and efficiency.

The Role of Roll Forming Machines

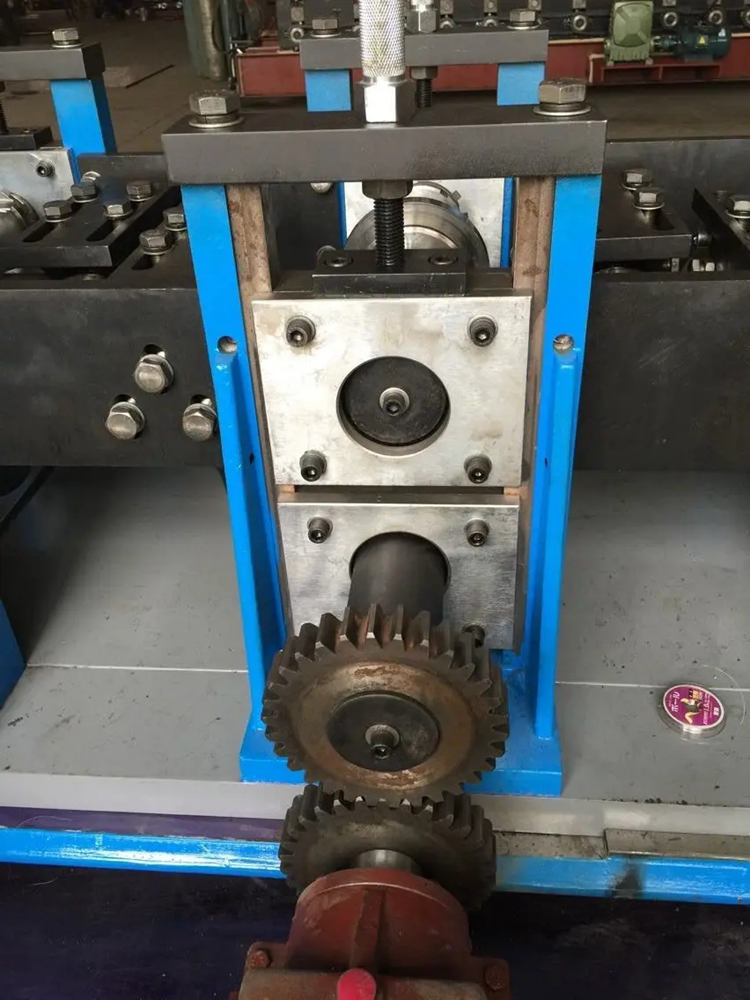

Roll forming is a cold-working process that produces long sections of shaped metal. In the context of ridge caps, the roll forming machine shapes metal sheets into the desired profile with precision. The machine operates by feeding a continuous strip of material through a series of rollers that gradually shape it into the final product. This method is preferred for its efficiency, allowing for mass production while maintaining consistent quality in each tile produced.

Features of Ridge Cap Tile Roll Forming Machines

1. Versatility Modern ridge cap tile roll forming machines can work with a variety of materials, including galvanized steel, stainless steel, and aluminum. This versatility allows manufacturers to meet diverse market demands and design preferences.

2. Efficiency One of the main advantages of roll forming is its efficiency in production. These machines can produce large quantities of ridge caps in a short time, significantly reducing labor costs and increasing output. This efficiency makes them a valuable asset for roofing contractors and manufacturers alike.

3. Customization Many roll forming machines come equipped with advanced technology that allows for customization of the ridge cap design. This means that manufacturers can produce ridge caps in various shapes, sizes, and color finishes, accommodating specific project requirements or aesthetic preferences.

4. Quality Control Integrated quality control systems ensure that each ridge cap tile meets stringent standards. With sensors and cameras monitoring the production process, manufacturers can detect defects early and make necessary adjustments, resulting in higher-quality finished products.

5. Automation Today's machines often feature automated systems that streamline the entire production process. From loading the material to cutting the finished tiles, automation reduces manual labor and minimizes errors, further enhancing production efficiency.

Conclusion

The Ridge Cap Tile Roll Forming Machine represents a significant advancement in roofing material production. Its ability to produce high-quality, consistent, and aesthetically pleasing ridge caps is transforming the way roofs are constructed and finished. By incorporating advanced technology, these machines not only improve productivity but also reduce waste and costs associated with traditional manufacturing methods.

As the demand for durable and visually appealing roofing solutions continues to grow, the importance of efficient production systems like the ridge cap tile roll forming machine will only increase. This innovative technology not only caters to the current market needs but also sets the stage for future developments in roofing systems. With sustainability and efficiency at the forefront of the construction industry, these machines are more than just tools; they are catalysts for change, pushing the boundaries of what is possible in architectural design and functionality.

In summary, the ridge cap tile roll forming machine stands as a vital component in the modern roofing landscape, ensuring that builders can deliver high-quality, durable, and attractive roofing solutions that meet the diverse needs of their clients.