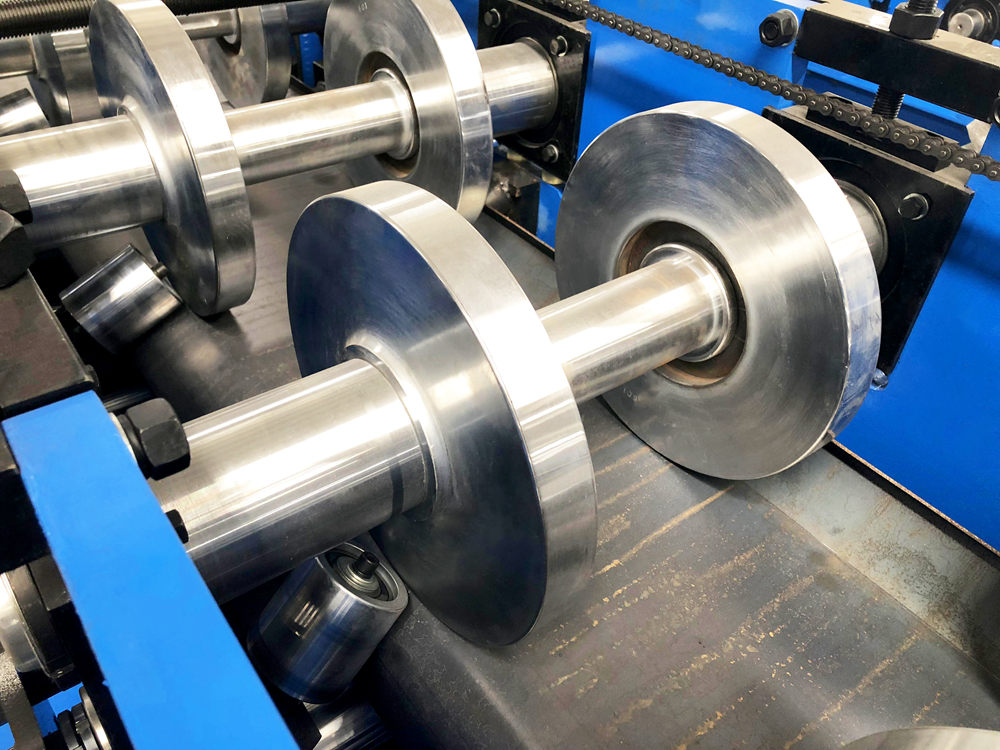

The pipe thread rolling machine is a transformative innovation in the machining and manufacturing industry, offering significant advancements over traditional methods of thread cutting and tapping. Engineered for precision and efficiency, these machines are based on sophisticated mechanisms that utilize cold working processes to create threads by displacing material rather than removing it. This not only results in stronger threads but also extends the life of materials due to the work-hardening effect imparted during threading.

Industry professionals have been advocating for the transition from conventional threading methods to the modern pipe thread rolling technique, citing enhanced durability and reduced production costs as key advantages. From a personal experience standpoint, implementing a pipe thread rolling machine drastically improved operational efficiency in my workshop. The transition facilitated a noticeable reduction in cycle time and tooling costs, allowing for both increased throughput and higher product quality.

The expertise involved in operating a pipe thread rolling machine lies in understanding its mechanics and the metallurgical properties of the materials being worked on. Unlike traditional threading machines, which require constant calibration and produce significant waste, a pipe thread rolling machine demands less maintenance and offers superior accuracy. The skill set required includes knowledge of machine settings, material flow, and pressure adjustments—all crucial for producing optimal thread integrity and consistency.

Authoritativeness in this domain arises from the machine’s proven track record across numerous industries, including oil and gas, automotive, and aerospace sectors, where reliability and precision are paramount. Leading manufacturers of pipe thread rolling machines are continuously innovating to enhance machine capabilities, integrating features such as automated control systems and real-time monitoring. This continuous evolution further validates the authoritative stance these machines hold in industrial applications.

Trustworthiness is a crucial factor when adopting new technologies, particularly in industries where safety and precision cannot be compromised. The trust bestowed upon pipe thread rolling machines is evident through their widespread adoption in demanding environments. Moreover, industry standards and certifications reinforce their reliability, ensuring compliance with stringent quality benchmarks.

To conclude, the pipe thread rolling machine represents an intersection of modern engineering prowess and practical industrial application. Its implementation not only reflects enhanced efficiencies and precision but also signifies a commitment to sustainability by minimizing material waste. As industries continue to seek ways to optimize operations, the pipe thread rolling machine stands out as a testament to the intelligent application of scientific principles, reaffirming its role as a cornerstone in contemporary manufacturing processes.