The Competitive Landscape of Steel Cable Tray Roll Forming Machines

In the rapidly evolving world of manufacturing, the demand for efficient and cost-effective production methods is ever-increasing. One of the prominent innovations in this sphere is the steel cable tray roll forming machine. This machinery plays a crucial role in the production of cable trays, which are essential components in various industries, including electrical engineering, construction, and telecommunications. Understanding the competitive dynamics surrounding these machines can provide insights into market trends, technological advancements, and the overall landscape of steel cable tray manufacturing.

Understanding Steel Cable Tray Roll Forming Machines

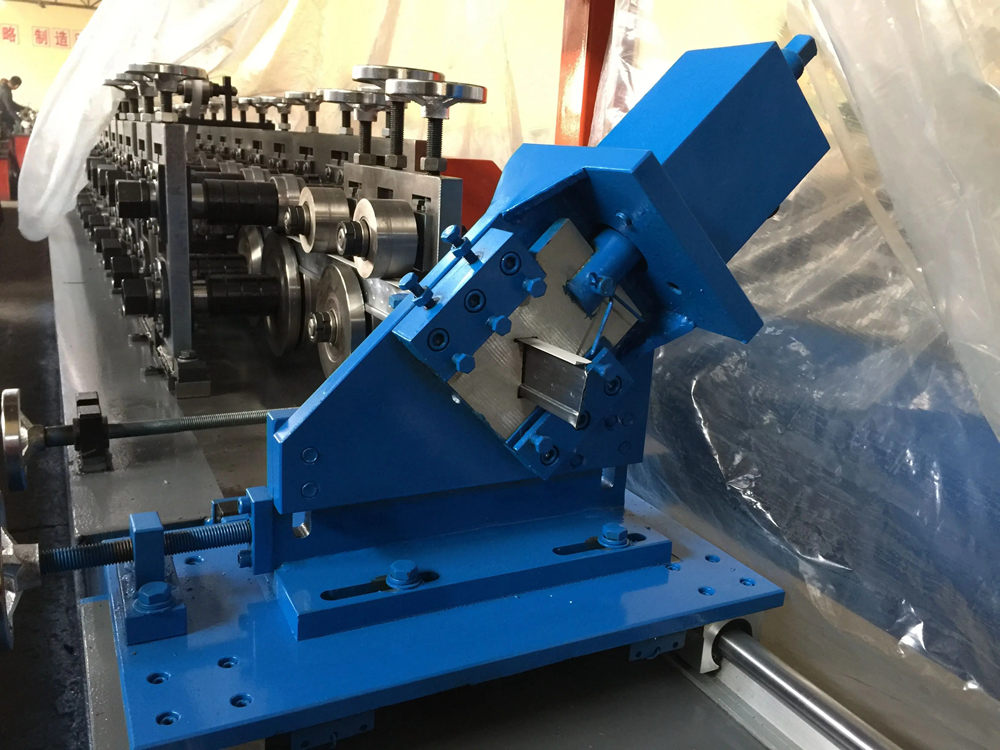

Roll forming is a continuous bending process used to create long lengths of metal profiles with the desired cross-section. A steel cable tray roll forming machine automates this process for the production of cable trays that support and manage electrical cables. The advantages of using these machines include high production efficiency, consistent quality, and material conservation. They can produce various tray designs, including ladder, perforated, and solid bottom types, providing flexibility for manufacturers to meet diverse customer needs.

Competitive Pricing Strategies

The competitive pricing of steel cable tray roll forming machines is influenced by several factors, including material costs, manufacturing processes, and the level of technological innovation incorporated into the machines. Manufacturers must balance the cost of materials—mainly steel—and the operational efficiency of their machines while ensuring they remain competitive against domestic and international players.

One effective strategy for maintaining competitive pricing is through automation and technology integration. Advanced machines equipped with features such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs) allow for streamlined operations, reducing labor costs and minimizing errors during production. This not only enhances efficiency but also leads to lower production costs, allowing manufacturers to offer their machines at competitive prices.

Market Trends

As the demand for steel cable trays continues to rise, driven by urbanization and technological advancements, the market for roll forming machines is expected to grow. One notable trend is the increasing preference for eco-friendly manufacturing processes. Manufacturers are exploring sustainable materials and energy-efficient technologies, which could influence the pricing strategies for steel cable tray roll forming machines.

Additionally, the globalization of supply chains means that manufacturers must keep up with international competitors who may have lower production costs. Companies are responding by investing in research and development to enhance the capabilities of their machines. This includes developing machines that can produce a wider range of tray sizes and styles, catering to various market segments.

Technological Advancements

Innovation in roll forming technology is reshaping the competitive landscape. Features such as modular designs, which allow for easy adjustments and reconfigurations, are becoming increasingly common. These advancements make it easier for manufacturers to transition between different production runs, thus enhancing flexibility and responsiveness to market demands.

Moreover, the integration of Industry 4.0 technologies, including the Internet of Things (IoT) and smart manufacturing systems, is revolutionizing the operation of roll forming machines. These technologies enable real-time monitoring and predictive maintenance, leading to decreased downtime and improved productivity. Companies that adopt these technologies can significantly reduce operational costs, further bolstering their competitive pricing strategies.

Conclusion

The market for steel cable tray roll forming machines is characterized by a competitive pricing landscape shaped by various factors, including technological advancements, manufacturing efficiencies, and global competition. As manufacturers strive to meet the growing demand for cable trays, the emphasis on innovative production techniques and cost-effective strategies will be paramount.

Staying ahead in this competitive market requires a continuous commitment to technology and quality improvement. By investing in modern roll forming equipment that offers enhanced capabilities, manufacturers can not only meet evolving customer demands but also secure their place in the competitive landscape. With the right strategies, businesses can effectively navigate the complexities of pricing and technology in the steel cable tray roll forming market, ensuring sustained growth and profitability.