Understanding Color Steel Rain Pipe Roll Forming Machines

In the realm of construction and architecture, the functionality and aesthetics of rainwater drainage systems play a crucial role. One significant innovation that has emerged in this field is the color steel rain pipe roll forming machine. This advanced piece of equipment facilitates the production of high-quality rain pipes from color-coated steel, effectively combining durability with attractive design.

What is a Roll Forming Machine?

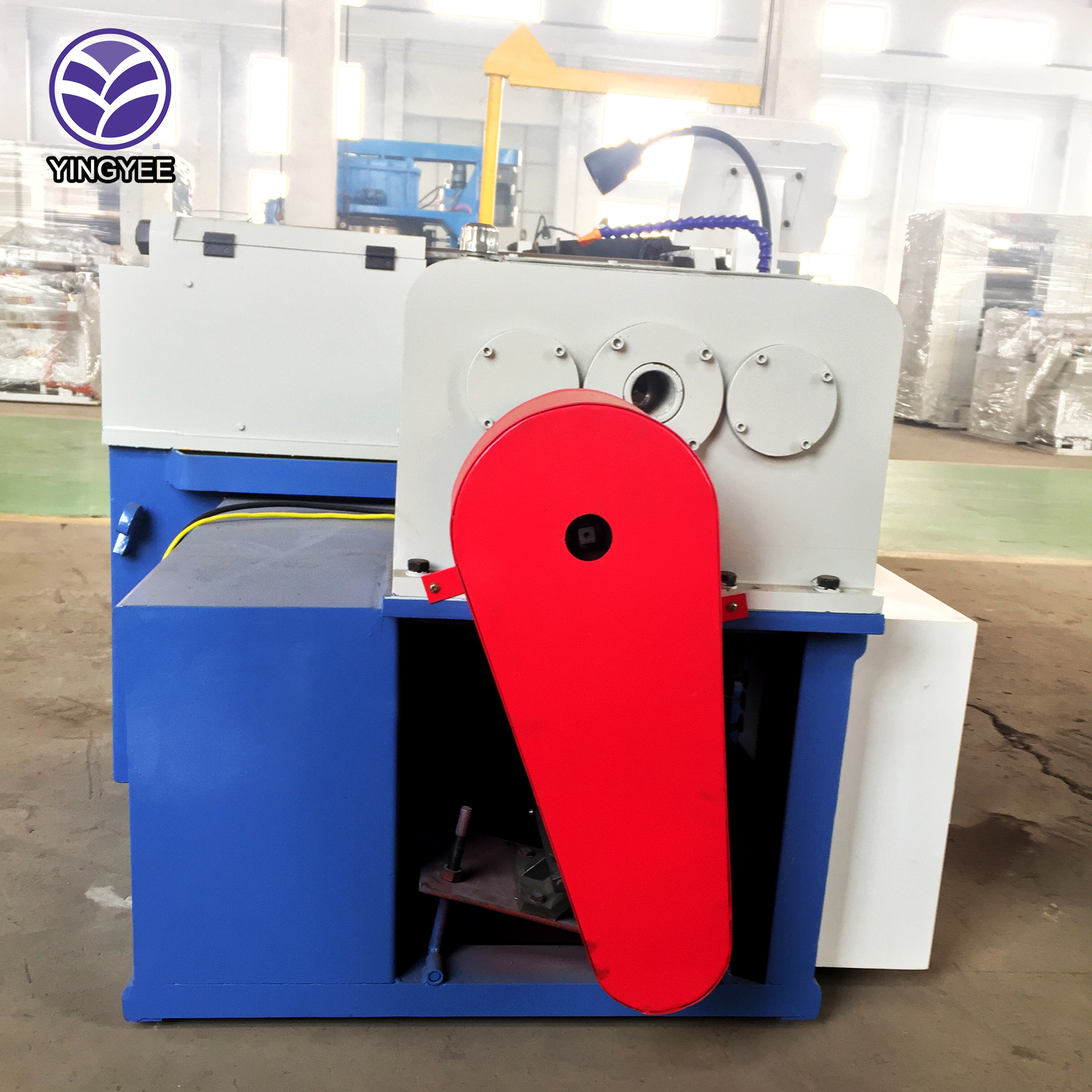

A roll forming machine is a type of industrial equipment used to shape metal sheets into specific profiles. It operates by passing a continuous strip of metal through a series of rollers, each designed to progressively bend the metal into the desired shape. For rain pipe production, this process allows for the creation of pipes with precise dimensions, smooth surfaces, and consistent qualities, essential for effective rainwater drainage.

Features of Color Steel Rain Pipe Roll Forming Machines

Color steel rain pipe roll forming machines are typically equipped with several key features that enhance their performance and efficiency.

1. High Precision These machines are designed to produce pipes with high accuracy. The rollers are meticulously crafted to ensure that the final product meets stringent size and shape specifications.

2. Durability Given that rain pipes are exposed to varying weather conditions, the color steel used in manufacturing is often treated for corrosion resistance. The roll forming machine ensures that the integrity of the steel is maintained throughout the shaping process.

3. Customizable Profiles Different architectural designs may require specific pipe profiles. Color steel rain pipe roll forming machines can be adjusted to create various shapes and sizes to suit specific project needs.

4. High Efficiency These machines can operate at high speeds, allowing manufacturers to produce large volumes of pipes in a short time. This efficiency is particularly beneficial in meeting the demands of large construction projects.

5. Automation Modern roll forming machines often come with automation features, including programmable logic controllers (PLCs). This automation not only enhances efficiency but also reduces the likelihood of human error, leading to more consistent product quality.

Advantages of Using Color Steel for Rain Pipes

The choice of color steel in manufacturing rain pipes brings numerous advantages. Firstly, it offers an aesthetically pleasing appearance that complements various architectural styles. The color coating can be customized to match a building's exterior, enhancing overall visual appeal.

Secondly, color steel is exceptionally durable and resistant to rust and weather damage. This longevity translates into lower maintenance costs over time, making it a cost-effective choice for builders and homeowners alike. Furthermore, the lightweight nature of color steel allows for easier handling and installation.

Applications of Color Steel Rain Pipe Roll Forming Machines

Color steel rain pipes produced by roll forming machines are used in a variety of applications. They are integral to roofing systems, acting as conduits for channeling rainwater away from buildings. This is crucial in preventing water accumulation, which can lead to structural damage or mold growth.

Additionally, these pipes are well-suited for use in commercial buildings with extensive roofing systems, residential developments, and even in architectural landmarks where aesthetics and functionality must be balanced.

Conclusion

The advent of color steel rain pipe roll forming machines represents a significant advancement in construction technology. By enabling the efficient production of durable and aesthetically pleasing rain pipes, these machines contribute to the improvement of rainwater drainage systems while meeting the diverse demands of modern architecture. As construction standards continue to evolve, the role of innovative machinery like the roll forming machine will only grow more vital in shaping the future of building design and sustainability. The integration of features that enhance precision, efficiency, and customization exemplifies how technology can elevate traditional practices, paving the way for new possibilities in construction.