The Evolution of Steel Pipe and Tube Mill Machines Innovations and Applications

In the world of manufacturing, steel pipe and tube mill machines play a crucial role in producing essential materials for various industries. These machines are designed to form steel into pipes and tubes, providing the backbone for construction, automotive, energy, and many other sectors. Understanding the evolution and functionality of these machines can offer insights into their significance in modern manufacturing processes.

Historical Context

The production of steel pipes dates back to the 19th century when industrialization began to take hold. Initially, pipes were forged manually, which was a labor-intensive and time-consuming process. However, with the advent of the industrial revolution and advancements in steelmaking technology, automated machines began to emerge. The first tube mills were introduced, which revolutionized the way pipes were produced. These early models laid the foundation for the sophisticated technologies we see in today's steel pipe and tube mills.

Design and Functionality

Modern steel pipe and tube mill machines are complex systems that integrate various technologies to ensure efficiency and precision. The core components of these machines include uncoilers, forming stations, welding sections, sizing sections, and cut-off machines.

1. Uncoiling The process begins with uncoiling a roll of steel strip, which is fed into the mill. The strip is then guided through the forming stations.

2. Forming At the forming stations, the steel strip is shaped into a tubular form. The design of these stations can vary depending on the desired diameter and thickness of the pipe or tube.

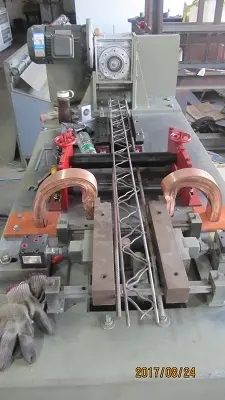

3. Welding Once the steel strip is formed into a tube, it must be welded to seal the seam. Various welding techniques, such as high-frequency induction welding or TIG welding, are employed to ensure a strong bond.

4. Sizing After welding, the tube is passed through sizing sections, where it is shaped to the correct specifications. This step is crucial for maintaining uniformity and quality.

5. Cutting Finally, the tube is cut to the required lengths using sophisticated cut-off machines, which provide precise length control and can operate at high speeds.

Technological Innovations

As industries evolve, so too do the technologies behind steel pipe and tube mill machines. Automation and digitalization are leading the charge, with many mills incorporating advanced control systems and data analytics to improve their efficiency. For example, industry 4.0 technologies allow for real-time monitoring and adjustments to the manufacturing process, significantly reducing waste and downtime.

Moreover, advancements in materials science have enabled the production of specialized pipes and tubes, such as those that can withstand extreme temperatures or corrosive environments. These innovations cater to niche markets, such as oil and gas exploration, aerospace, and chemical processing, where standard pipes would fail.

Environmental Considerations

The steel industry is under increasing pressure to reduce its environmental footprint. Modern steel pipe and tube mills are adopting greener practices. Many are implementing recycling programs and utilizing renewable energy sources to minimize emissions. Furthermore, advancements in equipment efficiency and waste reduction technologies contribute to a more sustainable production cycle.

Conclusion

Steel pipe and tube mill machines represent a significant facet of the manufacturing industry, driving the production of essential components that support global infrastructure. As these machines continue to evolve through technological advancements, they not only enhance efficiency and precision but also contribute to sustainable practices. As we look to the future, the role of steel pipes and tubes in various applications will continue to grow, underscoring the importance of innovation in machine design and operation. The evolution of steel pipe and tube mill machines is a testament to the industry’s commitment to meeting the demands of a changing world, ensuring that these vital materials remain a cornerstone of modern civilization.