The Steel Purlin Machine Revolutionizing Steel Construction

In the ever-evolving world of construction, efficiency and innovation are paramount. Among the various advancements in construction technology, the steel purlin machine has emerged as a game-changer. This machine not only streamlines the process of producing purlins but also ensures that the quality meets the stringent requirements of modern building practices.

Understanding Steel Purlins

Steel purlins are horizontal members used in the roof and wall systems of buildings. They provide support for roofing sheets or wall cladding, allowing for efficient load distribution and structural integrity. Traditionally, purlins have been fabricated through labor-intensive processes that can be both time-consuming and costly. However, with the introduction of steel purlin machines, the production process has undergone a significant transformation.

The Mechanics of Steel Purlin Machines

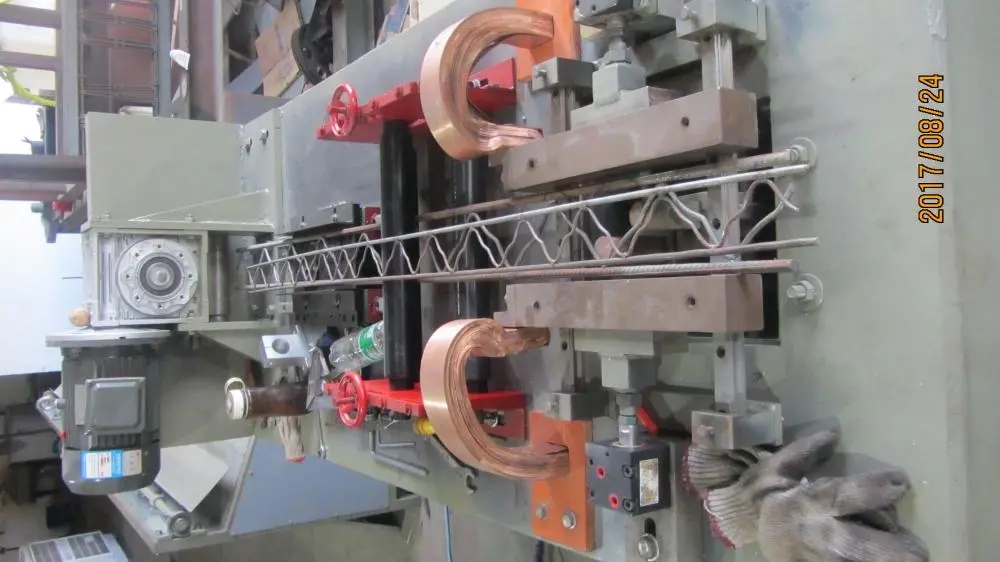

A steel purlin machine is designed to roll-form steel into various profiles, including C, Z, and U shapes. These profile shapes are essential for different applications in construction. The machine operates through a continuous process that involves feeding a coil of steel through a series of rollers. As the steel passes through, it is gradually shaped into the desired profile.

One of the main advantages of using a steel purlin machine is its ability to produce purlins on-demand. This efficiency reduces storage costs and waste associated with leftover materials. Additionally, modern machines are equipped with advanced control systems that ensure precision in dimensions and thickness, which is crucial for meeting construction standards.

Benefits of Utilizing Steel Purlin Machines

1. Cost-Effectiveness Steel purlin machines significantly reduce labor costs and material wastage. The automation of the production process means fewer workers are needed to oversee operations, leading to lower overheads for construction companies.

2. Faster Production Times With the capability to produce purlins quickly, contractors can adhere to tight project timelines. The ability to manufacture purlins on-site means contractors can get materials when they need them, reducing delays in project completion.

3. Quality Control Modern steel purlin machines are equipped with advanced technology that ensures each purlin is manufactured to precise specifications. High-quality output is critical in construction, as it ensures the safety and durability of the building.

4. Versatility These machines can be adjusted to produce various profiles and sizes, making them suitable for different types of construction projects, from residential buildings to large industrial warehouses.

5. Sustainability With the construction industry increasingly focusing on sustainable practices, steel purlin machines contribute by minimizing waste and allowing for the use of recycled materials. This aligns with the global push towards eco-friendly building methods.

Real-World Applications

The use of steel purlin machines has gained traction in various construction projects around the world. For instance, in commercial real estate development, where large spans and open spaces are often required, steel purlins provide the necessary support while minimizing the number of columns or supports needed. This not only enhances the aesthetic appeal of commercial spaces but also maximizes usable floor area.

Conclusion

In conclusion, the steel purlin machine marks a significant advancement in modern construction technology. By combining efficiency, precision, and versatility, it stands at the forefront of innovation within the industry. As construction projects continue to demand higher standards and faster execution, the reliance on steel purlin machines is set to grow, making them an essential component of contemporary construction practices. Investing in this technology not only boosts productivity but also contributes to higher quality and more sustainable building solutions. As the industry progresses, it is clear that the steel purlin machine will play an integral role in shaping the future of construction.