The Importance of Cable Tray Punching Machines in Modern Industries

In today's fast-paced industrial environment, efficiency and precision are more crucial than ever. Among the many tools that enhance production processes, cable tray punching machines play a vital role. These machines specialize in punching holes into cable trays, which are essential for organizing and supporting electrical cables in both industrial and commercial settings. Understanding the significance and functionality of cable tray punching machines can provide valuable insights into their impact on various industries.

Cable trays serve as an effective way to manage and secure electrical wiring and cables, preventing tangling and reducing the risk of damage. As the demand for organized electrical systems grows, so does the need for effective manufacturing processes that can produce these cable trays efficiently. The cable tray punching machine addresses this need by automating the punching process, thus improving accuracy and reducing labor costs.

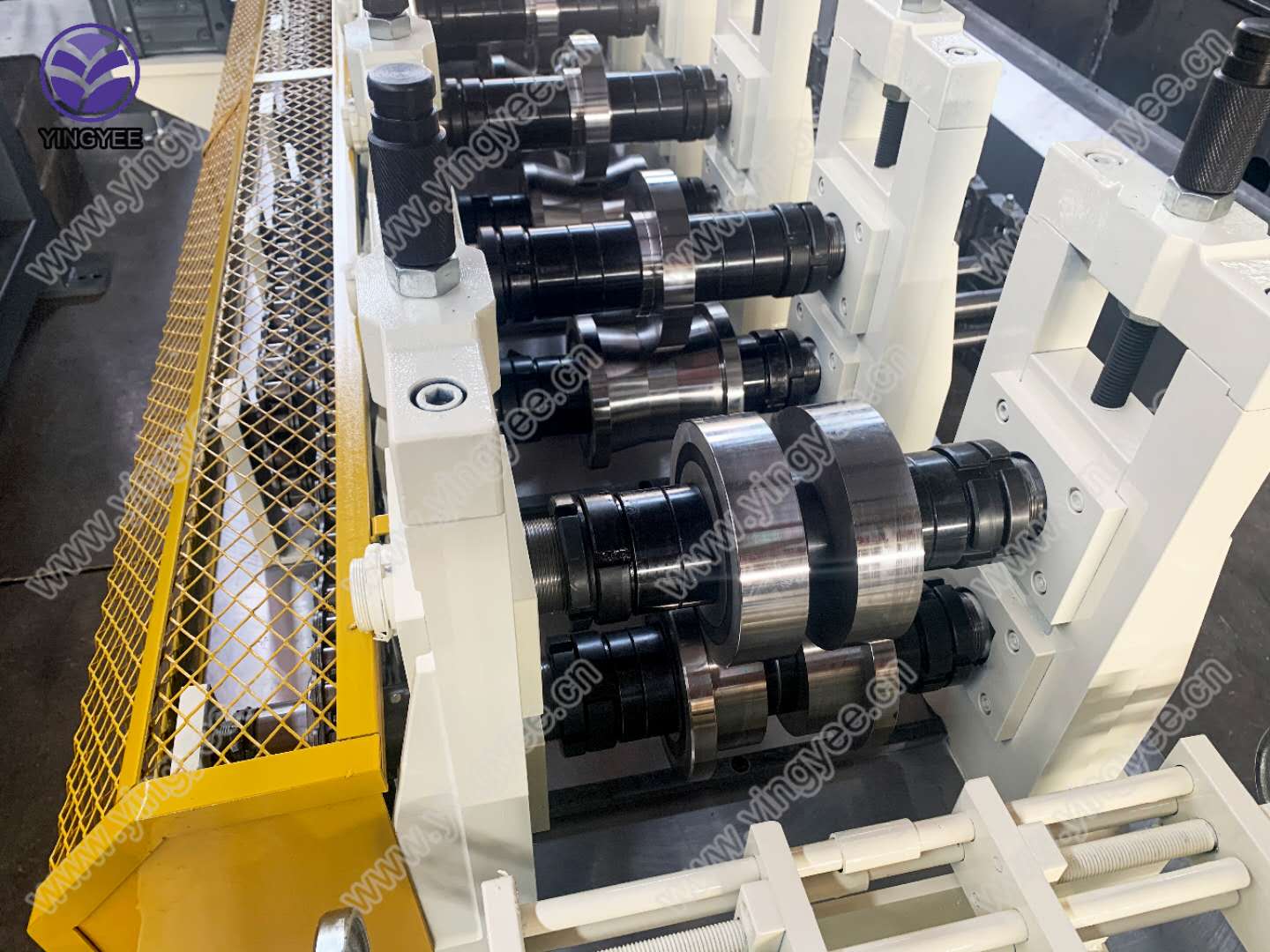

These machines are equipped with advanced technology that allows for precise hole placement and uniformity across multiple trays. This precision is crucial for ensuring that cables can be securely fastened and that there is adequate airflow around them to prevent overheating. Manual drilling or punching methods can lead to inconsistent results, which may compromise the integrity of the cable management system. By employing a cable tray punching machine, manufacturers ensure that each tray meets strict quality standards, which is critical in industries such as construction, telecommunications, and manufacturing.

Moreover, cable tray punching machines are designed for versatility. Many models can handle various sizes and materials, from aluminum to steel, making them suitable for a wide range of applications. The ability to easily switch between tray sizes and specifications allows manufacturers to respond quickly to changing demands, enhancing their competitiveness in the market.

Additionally, the operational efficiency of cable tray punching machines cannot be overstated. By automating the punching process, manufacturers can significantly reduce production times. This accelerated production not only meets tight deadlines but also allows companies to scale operations without a proportional increase in labor costs. Consequently, this leads to better resource allocation and increased profitability.

The implementation of cable tray punching machines also contributes positively to workplace safety. Automated processes minimize the need for manual intervention, thereby reducing the risk of injury associated with traditional punching or drilling methods. With enhanced safety features and automation, these machines provide a safer working environment for operators.

Furthermore, the impact of cable tray punching machines extends beyond manufacturing. They play a critical role in improving sustainability practices within industries. By optimizing the punching process, these machines reduce material waste and enhance overall production efficiency. This focus on sustainability aligns with the increasing emphasis on environmentally friendly practices within various sectors.

In conclusion, cable tray punching machines are indispensable tools in modern manufacturing processes. Their ability to enhance efficiency, precision, safety, and sustainability makes them a valuable asset in various industries. As businesses continue to seek innovative solutions to meet the evolving demands of the market, the importance of automated tools like cable tray punching machines will only continue to rise. Investing in such technology not only streamlines operations but also contributes to a more organized and efficient approach to cable management in electrical systems.