Exploring the Single Z Purlin Forming Machine

In the realm of modern construction and engineering, the efficiency and versatility of building materials play a crucial role in project success. One such innovation that has revolutionized the steel framework landscape is the Single Z Purlin Forming Machine. This specialized piece of equipment is designed to produce high-quality Z-shaped purlins, which serve as significant structural components in various construction applications.

Understanding Z Purlins

Z purlins are horizontal structural members that are designed to support roof and wall constructions. Their unique Z shape provides exceptional structural stability, allowing them to effectively withstand bending and twisting forces. These purlins are widely used in the construction of warehouses, factories, agricultural buildings, and commercial structures. Their lightweight nature, combined with strength and durability, makes Z purlins an excellent choice for modern construction.

The Functionality of the Single Z Purlin Forming Machine

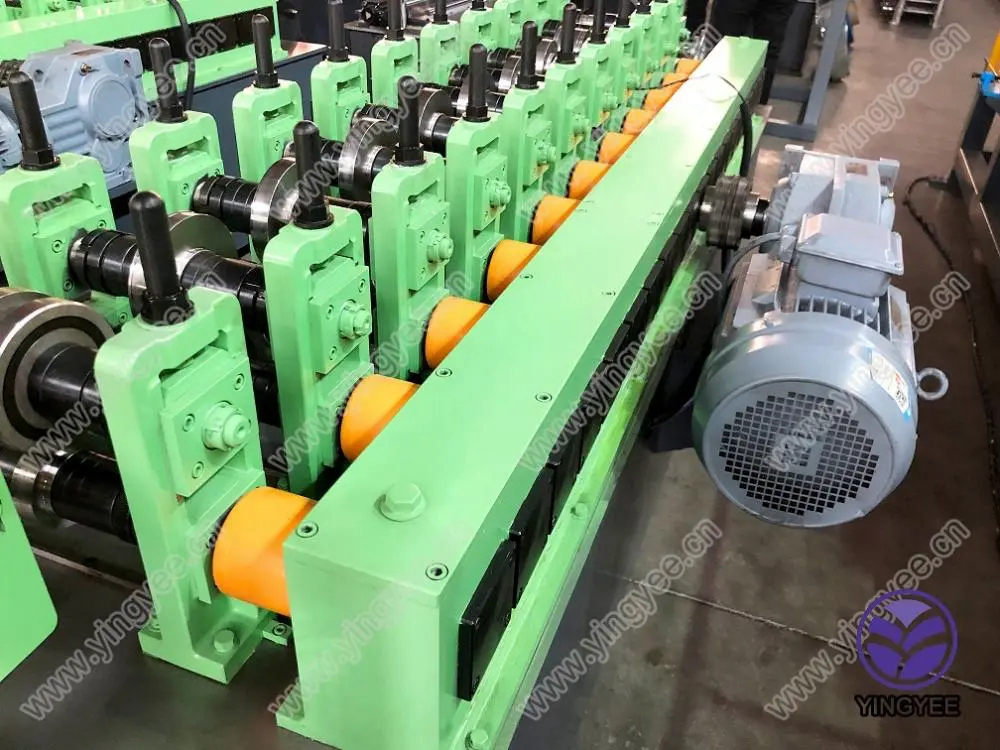

The Single Z Purlin Forming Machine automates the manufacturing process of Z purlins, allowing for high production efficiency and accuracy. This machine operates by taking flat metal sheets and feeding them through a series of rollers, which progressively shape the material into the desired Z profile. Equipped with advanced technology, these machines can produce purlins in various sizes and thicknesses to meet specific project requirements.

One of the significant advantages of using a Single Z Purlin Forming Machine is its ability to produce continuous lengths of purlins. This feature significantly reduces material wastage and the need for additional labor, making the manufacturing process more cost-effective. Moreover, these machines often come with adjustable settings, enabling operators to easily change specifications according to project demands.

Quality and Precision

Quality is paramount in construction, and the Single Z Purlin Forming Machine ensures that every purlin produced meets stringent industry standards. With precision engineering, these machines can achieve tolerances of millimeters, ensuring that the final product fits perfectly within the structural framework. Additionally, many machines incorporate automated control systems that allow for real-time monitoring of the production process, further enhancing quality assurance.

Economic Impact

Investing in a Single Z Purlin Forming Machine can lead to significant economic benefits for construction companies. By streamlining the manufacturing process, businesses can reduce labor costs and improve turnaround times for projects. Furthermore, the reduced wastage of materials contributes to lower operational costs, allowing companies to offer competitive pricing to clients.

Conclusion

The Single Z Purlin Forming Machine stands at the forefront of modern construction technology, delivering efficiency, quality, and cost savings. As the demand for robust and versatile building materials continues to rise, these machines will play an increasingly vital role in shaping the future of construction. For any company looking to improve their production capabilities and maintain high standards, investing in a Single Z Purlin Forming Machine is a strategic choice that promises substantial returns.