Understanding the Drywall Forming Machine Revolutionizing Construction

In the modern construction landscape, efficiency, precision, and cost-effectiveness are paramount. One of the innovations that have significantly transformed the drywall industry is the drywall forming machine. This sophisticated piece of machinery is designed to streamline the production process of drywall, also known as gypsum board or plasterboard, which is essential for constructing walls and ceilings in residential and commercial buildings.

What is a Drywall Forming Machine?

A drywall forming machine is a production line that automates the manufacturing of drywall sheets. This machine combines various processes, including mixing, forming, pressing, and cutting, into a seamless workflow. It enables manufacturers to produce high-quality drywall with standardized dimensions, thereby reducing manual labor and minimizing errors associated with traditional production methods.

The Production Process

The drywall production process typically involves several key steps

1. Material Preparation The primary raw material for drywall is gypsum, which is ground into a fine powder. The powder is then mixed with water and various additives to enhance its properties, such as fire resistance and moisture resistance.

2. Forming Once the mixture is prepared, it is spread onto a continuous moving conveyor belt, where it is formed into sheets of desired thickness. This stage is crucial as it determines the uniformity and quality of the final product.

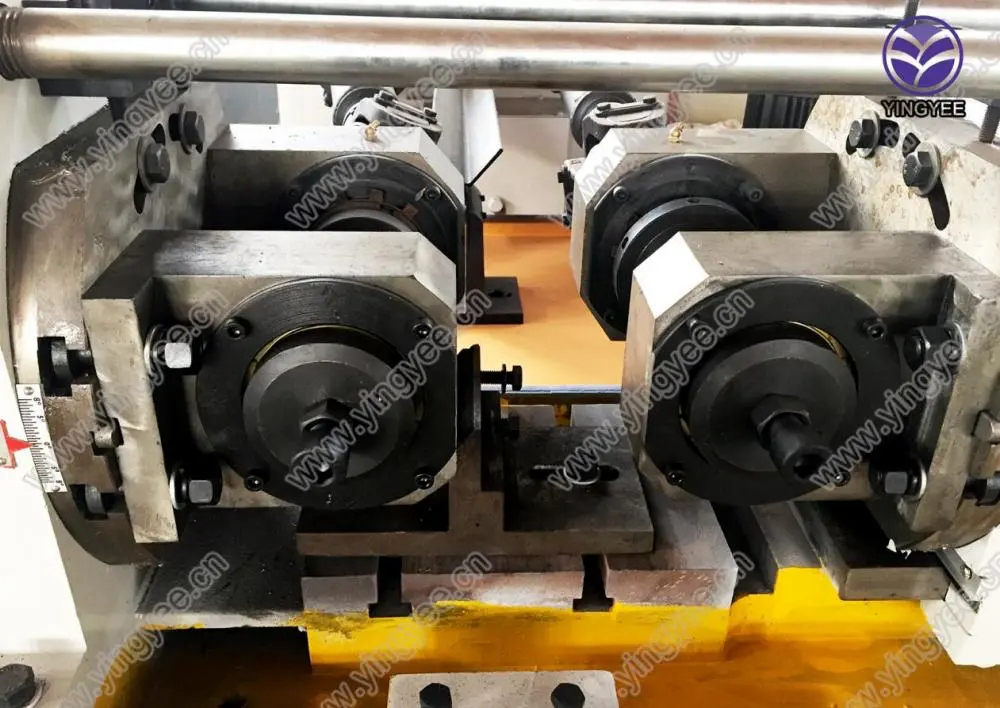

3. Pressing The formed sheets are then compressed using hydraulic or mechanical presses. This step is essential for achieving the desired density and strength of the drywall, ensuring it can withstand the rigors of construction and everyday use.

4. Cutting After pressing, the large sheets are cut into standard sizes typically used in the market, such as 4x8 feet or 4x12 feet. This automated cutting process ensures that each sheet is accurate in dimension, making them easy to handle and install.

5. Drying and Finishing The final step involves drying the sheets to remove excess moisture and curing them for added strength. Once dried, the sheets may undergo additional treatments, like paper lamination, to enhance their performance.

Benefits of Drywall Forming Machines

The integration of drywall forming machines into production facilities offers numerous benefits

- Increased Efficiency Automation reduces production time significantly. The ability to produce drywall in continuous sheets means that large quantities can be manufactured quickly, meeting high demand without compromising quality.

- Cost-Effectiveness By minimizing labor costs and material waste, manufacturers can lower production expenses. The resulting savings can be passed on to consumers, making drywall more affordable.

- Consistency and Quality Control Automated processes ensure that every sheet of drywall produced meets strict quality standards. This consistency is vital for builders who rely on uniform materials for seamless installations.

- Reduction of Human Error With fewer manual handling processes, the likelihood of errors decreases. This not only enhances product quality but also improves workplace safety by reducing the risk of workplace accidents.

The Future of Drywall Manufacturing

As the construction industry continues to evolve, so too does the technology behind drywall forming machines. Advancements in robotics, artificial intelligence, and data analytics promise to further enhance efficiency and product quality. Manufacturers are exploring eco-friendly materials and sustainable production practices to meet the growing demand for green building solutions.

In conclusion, drywall forming machines represent a significant leap forward in the construction industry. By embracing automation, manufacturers can produce high-quality drywall efficiently and economically, ensuring that builders have the materials they need to create safe and beautiful spaces. As technology progresses, we can expect these machines to become even more sophisticated, further revolutionizing how drywall is made and utilized in construction.