The Importance of Roofing Metal Machines in Modern Construction

In recent years, the construction industry has witnessed significant advancements in technology, particularly in the manufacturing of roofing materials. One of the most vital components of modern roofing solutions is the roofing metal machine. These machines play an essential role in producing high-quality metal roofing panels, which are becoming increasingly popular due to their durability, energy efficiency, and aesthetic appeal. This article explores the significance of roofing metal machines, their functionality, and the benefits they bring to the construction sector.

Understanding Roofing Metal Machines

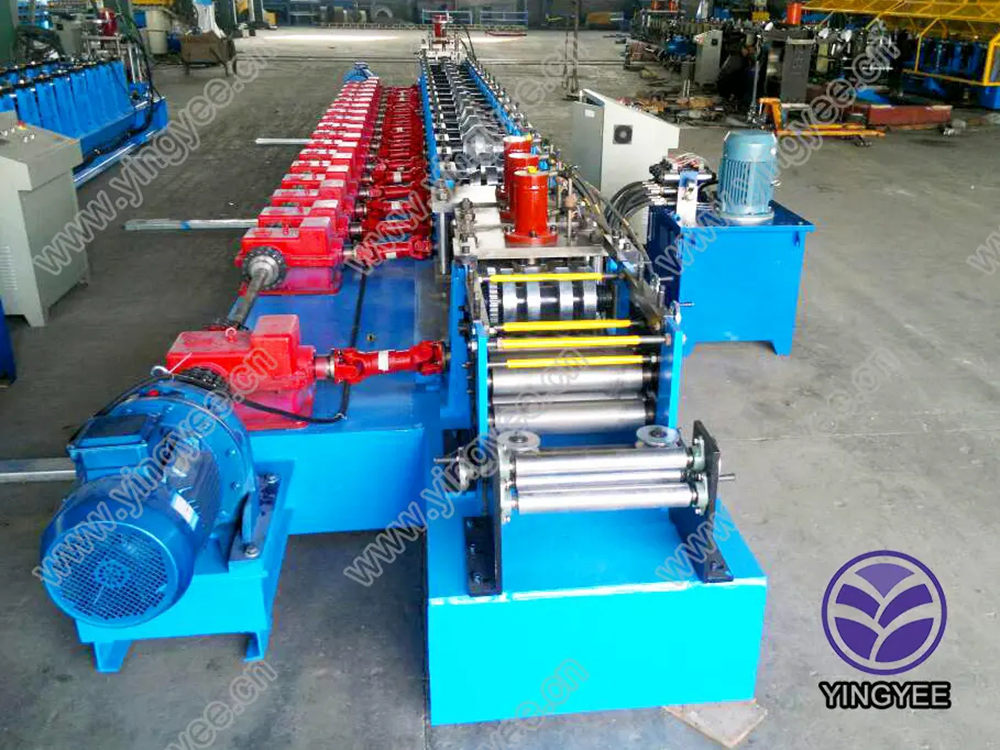

Roofing metal machines are specialized equipment designed to manufacture metal roofing sheets and panels. They use various processes, including roll forming, cutting, and bending, to create roofing materials from metal coils, typically made of steel or aluminum. These machines can be customized to produce different profiles and thicknesses, catering to various architectural styles and requirements. The precision and efficiency offered by roofing metal machines allow manufacturers to produce large quantities of roofing materials quickly, reducing lead times and meeting the demands of both residential and commercial construction projects.

The Functionality of Roofing Metal Machines

At the heart of roofing metal machines is the roll-forming process. This involves feeding a flat metal coil into the machine, where it passes through a series of rollers. These rollers gradually shape the metal into the desired profile, which could be corrugated, standing seam, or other designs suitable for roofing applications. Once formed, the metal sheets are cut to the required lengths, ensuring consistency and minimal waste. Advanced roofing metal machines may also feature additional functions, such as embossing or pre-painting, enhancing the final product's aesthetic appeal and protective qualities.

Benefits of Using Metal Roofing

1. Durability and Longevity Metal roofs are renowned for their strength and long lifespan. When properly installed and maintained, metal roofing can last over 50 years, far outlasting traditional asphalt shingles, which typically require replacement every 20-30 years. Roofing metal machines enable manufacturers to produce panels that meet stringent quality standards, ensuring that the end product is reliable and resilient in various weather conditions.

2. Energy Efficiency Metal roofing reflects solar radiant heat, which can help to keep buildings cooler in hot climates. This property can lead to significant energy savings, as homeowners and businesses may see reduced air conditioning costs during summer months. Roofing metal machines contribute to this energy efficiency by allowing for the production of roofing panels with reflective coatings that enhance this beneficial attribute.

3. Sustainability Metal roofing is often made from recycled materials and is itself recyclable at the end of its life. Using roofing metal machines that optimize the material output can further reduce waste, contributing to more sustainable construction practices. This appeal to environmentally conscious consumers is increasingly influencing the choice of roofing materials in new builds and renovations.

4. Aesthetic Versatility Modern roofing metal machines allow for the creation of a wide variety of styles, colors, and finishes. Homeowners and architects can choose from different profiles and textures, ensuring that the roofing complements the overall design of the building. This versatility makes metal roofing an attractive choice for diverse architectural styles, from contemporary to traditional.

5. Quick Installation Due to the precision and consistency of products manufactured by roofing metal machines, installation is often quicker and more straightforward. The lightweight nature of metal panels compared to traditional roofing materials also facilitates easier handling and installation, reducing labor costs and time on site.

Conclusion

As the construction industry continues to evolve, the role of roofing metal machines has become increasingly significant. These machines not only streamline the production of metal roofing but also contribute to the overall efficiency, sustainability, and aesthetic appeal of modern construction projects. With the growing demand for durable and energy-efficient roofing solutions, roofing metal machines are poised to play a pivotal role in shaping the future of the industry, making them an indispensable asset for manufacturers and builders alike. Investing in advanced roofing metal technology will continue to drive innovation, ensuring that the construction sector meets the demands of tomorrow's architectural challenges.