Purlin metal stud and track machines have revolutionized the way construction professionals approach the framework of buildings, bringing a blend of precision, efficiency, and flexibility to their projects. Having worked in the field for over a decade, I've witnessed firsthand the significant advantages these machines bring to the table.

At their core, purlin metal stud and track machines are designed to streamline the process of manufacturing metal framing components, typically used in the build-out of commercial infrastructures and, more recently, in residential projects. The technological advancements in these machines have allowed for unparalleled precision and speed, which translates into cost savings and enhanced structural reliability.

One of the primary advantages that these machines offer is their ability to produce components with exact specifications. This is crucial in modern construction, where precision dictates the safety and durability of a structure. By using advanced computer-aided design (CAD) systems, operators can tailor the designs to meet specific project requirements. This flexibility ensures that the resulting framework can support the loads and stresses it will encounter over its lifespan.

Another aspect worth noting, based on extensive field experience, is the speed at which these machines operate. Traditional methods of framing construction often involve manual measurements and cuts, which can be time-consuming and prone to human error. In contrast, purlin metal stud and track machines can churn out large quantities of standardized components in a fraction of the time, all while maintaining a high level of accuracy. This efficiency reduces labor costs and project timelines, which is a significant benefit for developers and contractors balancing tight schedules and budgets.

Furthermore, these machines enhance the structural integrity of buildings. Steel, the primary material used for purlins, studs, and tracks, is known for its strength and resistance to environmental elements such as wind and seismic activity. The precision manufacturing process ensures that each component interlocks seamlessly, providing a robust framework that contributes to the overarching stability and longevity of the building.

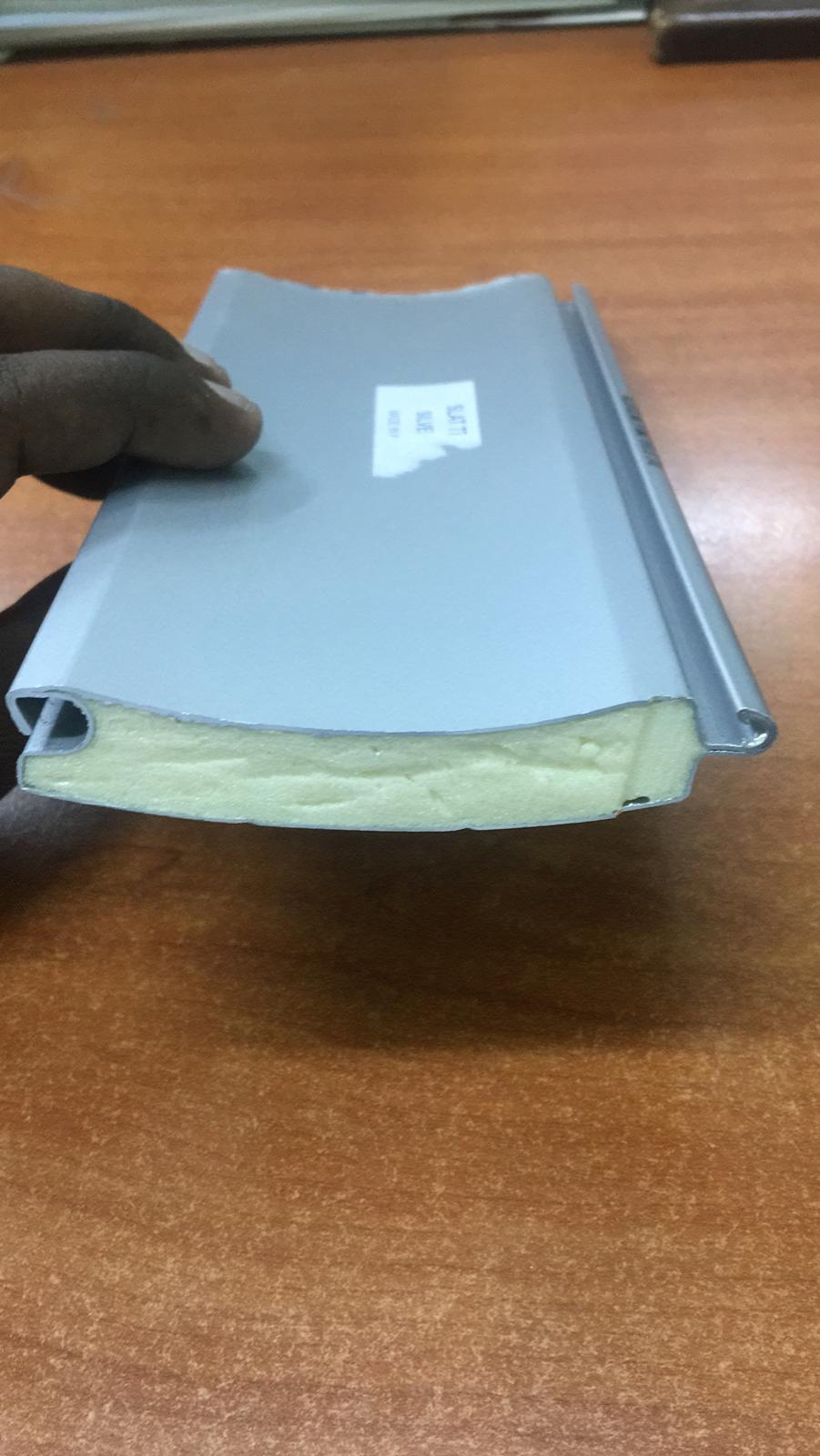

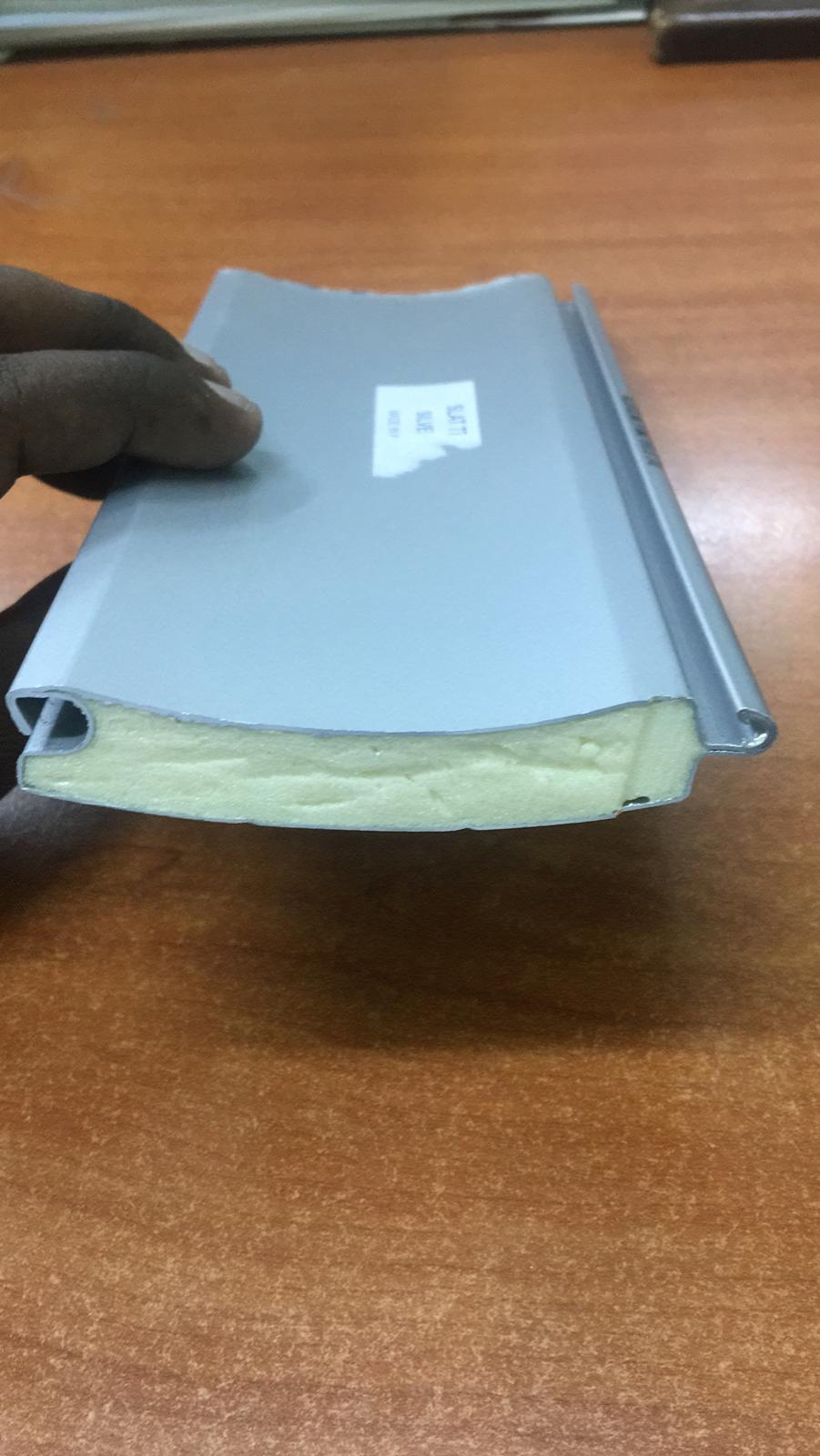

purlin metal stud and track machine

Having collaborated with numerous construction firms, I've observed an increasing trend of adopting these machines due to their contribution to sustainable building practices. Steel is highly recyclable,

and the precision of the manufacturing process minimizes waste. As sustainability becomes a cornerstone of modern construction, integrating machines that support eco-friendly practices is not just advantageous but necessary.

Additionally, the technological shift towards more intelligent machines has further propelled their usability. Many modern purlin metal stud and track machines come equipped with IoT (Internet of Things) capabilities, allowing for real-time monitoring and adjustments. This integration facilitates predictive maintenance, ensuring machines operate at peak efficiency while minimizing costly downtimes.

Trust in these machines is founded on their proven track record. Industry experts and seasoned construction managers vouch for the reliability and performance of these machines, often citing case studies where significant cost savings and enhanced structural outcomes were achieved. Authoritative bodies in the construction sector, including regulatory organizations, recognize the adherence of these machines to industry standards, which helps instill confidence in their application.

In summary, the adoption of purlin metal stud and track machines marks a significant milestone in construction methodologies, offering a comprehensive solution that addresses precision, efficiency, and sustainability. These machines are not only tools but partners in the building process, underscoring a commitment to innovation and excellence. With continued advancements, their role in shaping future skylines will only become more pronounced.