(mineral wool sandwich panel machine)

The global insulation materials market is projected to reach $82.1 billion by 2029 (CAGR 5.7%), driving demand for advanced mineral wool sandwich panel production lines. Recent industry analysis reveals:

Modern rock wool sandwich panel machines integrate six critical innovations:

| Parameter | AlphaMach X7 | EuroLine Pro | PanTech Master |

|---|---|---|---|

| Line Speed (m/min) | 22-28 | 18-25 | 25-32 |

| Panel Width Range (mm) | 800-1200 | 600-1000 | 900-1500 |

| Density Tolerance (%) | ±1.5 | ±2.8 | ±0.9 |

| Energy Consumption (kWh/m²) | 2.1 | 3.4 | 1.8 |

Leading manufacturers now offer three-tier customization:

Recent upgrades enable mineral wool sandwich panel production lines to switch between EPS and stone wool cores within 38 minutes.

2024 specification benchmarks for insulation cores:

Notable installations demonstrate versatility across climates:

Nordic Cold Storage Facility: Achieved U-value 0.19 W/m²K using 200mm panels

Middle Eastern Data Center: Maintained 22±0.5°C interior with 55°C ambient

Asian Automotive Plant: Reduced noise pollution by 37 dB(A)

Lifecycle analysis for modern systems shows:

The latest rock wool sandwich panel machines now feature blockchain-enabled quality tracing across all production stages.

(mineral wool sandwich panel machine)

A: A mineral wool sandwich panel machine automates the production of insulated panels by bonding mineral wool cores between metal or other rigid facings. It ensures precise layering, cutting, and shaping for consistent quality. This machinery is essential for industrial-scale insulation panel manufacturing.

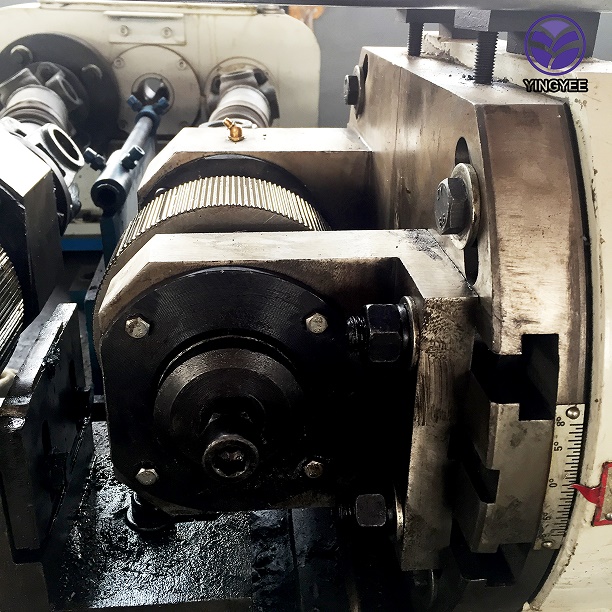

A: A complete production line includes uncoilers, conveyor systems, core-feeders, pressing machines, cutting units, and stacking tools. Advanced lines integrate PLC controls for automation and quality monitoring. These components work cohesively to optimize speed and material efficiency.

A: Rock wool sandwich panel machines are specifically designed to handle rock wool’s density and thermal properties. They feature reinforced feeding systems and higher-pressure presses to compact the fibrous material effectively. This specialization ensures durability and fire resistance in the final product.

A: Production speed depends on panel thickness, material density, and machine automation level. Advanced PLC-controlled systems minimize downtime and adjust parameters in real-time. Regular maintenance and operator expertise also significantly impact overall efficiency.

A: Yes, most modern machines allow customization of panel length, width, and thickness via programmable settings. Precision cutting units ensure accurate dimensions and clean edges. This flexibility caters to diverse construction and industrial requirements.