Wall Angel Production Line Transforming Drywall Manufacturing

In the evolving landscape of construction and interior design, the demand for efficient and versatile building materials has never been higher. Among these materials, drywall has emerged as a staple due to its affordability, ease of installation, and adaptability. At the forefront of this innovation is the Wall Angel production line, designed to enhance the manufacturing of drywall while ensuring high quality and sustainability.

The Wall Angel production line integrates state-of-the-art technology to streamline the drywall manufacturing process. It begins with the careful selection of raw materials, which include gypsum, additives, and recycled materials. The use of sustainable resources is a key feature of the Wall Angel system, aligning with industry efforts to minimize environmental impact. By emphasizing eco-friendly practices, manufacturers can meet the growing consumer demand for green building materials.

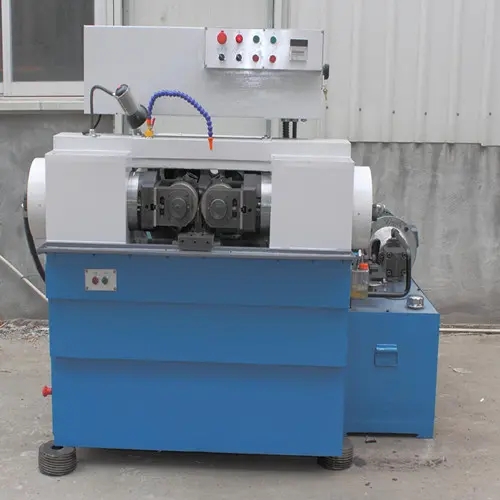

Once the raw materials are gathered, the production line utilizes advanced machinery to automate the mixing, forming, and drying processes. This automation not only increases efficiency but also reduces human error, ensuring that each sheet of drywall adheres to strict quality standards. The production line is designed for flexibility, accommodating various sizes and thicknesses of drywall to cater to diverse construction needs.

An essential component of the Wall Angel production line is its capacity for real-time monitoring and quality control. Sensors and software are employed to track the production process, identifying any deviations from the desired specifications. This proactive approach not only minimizes waste but also enhances the overall quality of the finished product. As a result, builders and contractors can rely on Wall Angel drywall for their projects, knowing it meets or exceeds industry benchmarks.

Moreover, the Wall Angel production line supports rapid scalability, allowing manufacturers to adjust output according to market demands. This capability is invaluable in today’s fast-paced construction environment, where project timelines can be tight and client expectations high.

In conclusion, the Wall Angel production line symbolizes a significant advancement in drywall manufacturing. By combining sustainability, automation, and quality control, it offers a reliable solution for meeting the growing needs of the construction industry. As building trends evolve, innovations like the Wall Angel will continue to shape the future of drywall production, ensuring that construction professionals have access to the best materials available.