Precision Roll Forming Machines Revolutionizing the Manufacturing Landscape

In the realm of modern manufacturing, precision is paramount. Industries ranging from automotive to construction constantly seek ways to enhance efficiency, reduce waste, and produce high-quality products. One of the most effective solutions to meet these demands is the use of precision roll forming machines. These machines have revolutionized the way materials are shaped and processed, offering numerous advantages over traditional manufacturing techniques.

What is Roll Forming?

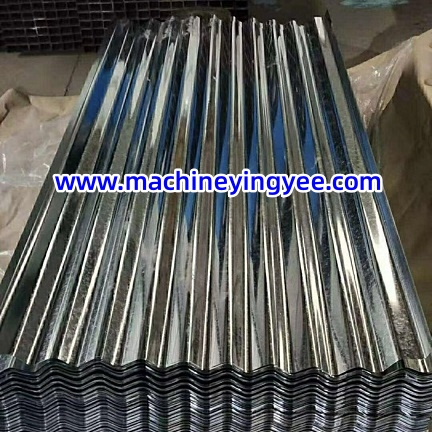

Roll forming is a continuous bending operation in which a long strip of metal, typically coiled steel, is passed through a series of rollers that progressively shape it into the desired cross-section. This process is particularly advantageous for producing consistent and uniform shapes at high volumes. By utilizing precision roll forming machines, manufacturers can create parts with exact dimensions and tight tolerances, which is essential in applications that require high precision.

Advantages of Precision Roll Forming Machines

1. High Accuracy and Consistency Precision roll forming machines are designed to deliver exceptional accuracy, ensuring that each part produced conforms to specified dimensions. This consistency minimizes the need for secondary operations and reduces material waste.

2. Increased Production Efficiency These machines operate at high speeds, which allows for the rapid production of large quantities of components. The continuous nature of the roll forming process streamlines manufacturing, contributing to shorter lead times and improved overall productivity.

3. Material Versatility Precision roll forming can be performed on various materials, including steel, aluminum, and even specialized alloys. This versatility enables manufacturers to select the most suitable material for their specific applications, leading to better performance and reduced costs.

4. Reduced Waste and Cost-Effectiveness Unlike traditional machining processes that often remove substantial amounts of material, roll forming retains the majority of the original material. This characteristic not only reduces waste but also minimizes production costs, making it a more sustainable option.

5. Ability to Create Complex Shapes Modern precision roll forming machines can produce intricate profiles and shapes that would be challenging or impossible to achieve with other manufacturing methods. This capability allows design engineers greater freedom when developing innovative products.

Applications Across Industries

Precision roll forming machines find applications in a variety of industries. In the automotive sector, they are used to manufacture components such as structural frames, door frames, and other critical parts that require stringent quality control. The construction industry utilizes roll-formed products for applications like roof trusses, wall studs, and HVAC ducts.

In addition to automotive and construction, precision roll forming has become vital in producing components for electronics, appliances, and even furniture. Its adaptability allows various sectors to benefit from its efficiencies and the high-quality results it provides.

The Future of Precision Roll Forming

As technology continues to advance, so does the potential for precision roll forming machines. Innovations in automation, computer numerical control (CNC), and Industry 4.0 technologies are enhancing the capabilities of these machines, allowing for smarter and more efficient production processes. Manufacturers are increasingly incorporating IoT (Internet of Things) solutions into their roll forming lines, enabling real-time monitoring and predictive maintenance—further optimizing production efficiency.

Moreover, the emphasis on sustainability in manufacturing is driving the development of more eco-friendly roll forming processes. By reducing material waste and energy consumption, precision roll forming aligns with the growing demand for sustainable manufacturing practices.

Conclusion

Precision roll forming machines are a game changer in the manufacturing industry, offering a blend of speed, accuracy, and cost-effectiveness that traditional methods cannot match. As industries continue to evolve, the importance of efficient and precise manufacturing processes will only grow. Embracing the technologies and capabilities of precision roll forming will allow manufacturers to stay competitive, innovate, and meet the increasingly stringent demands of today's market.