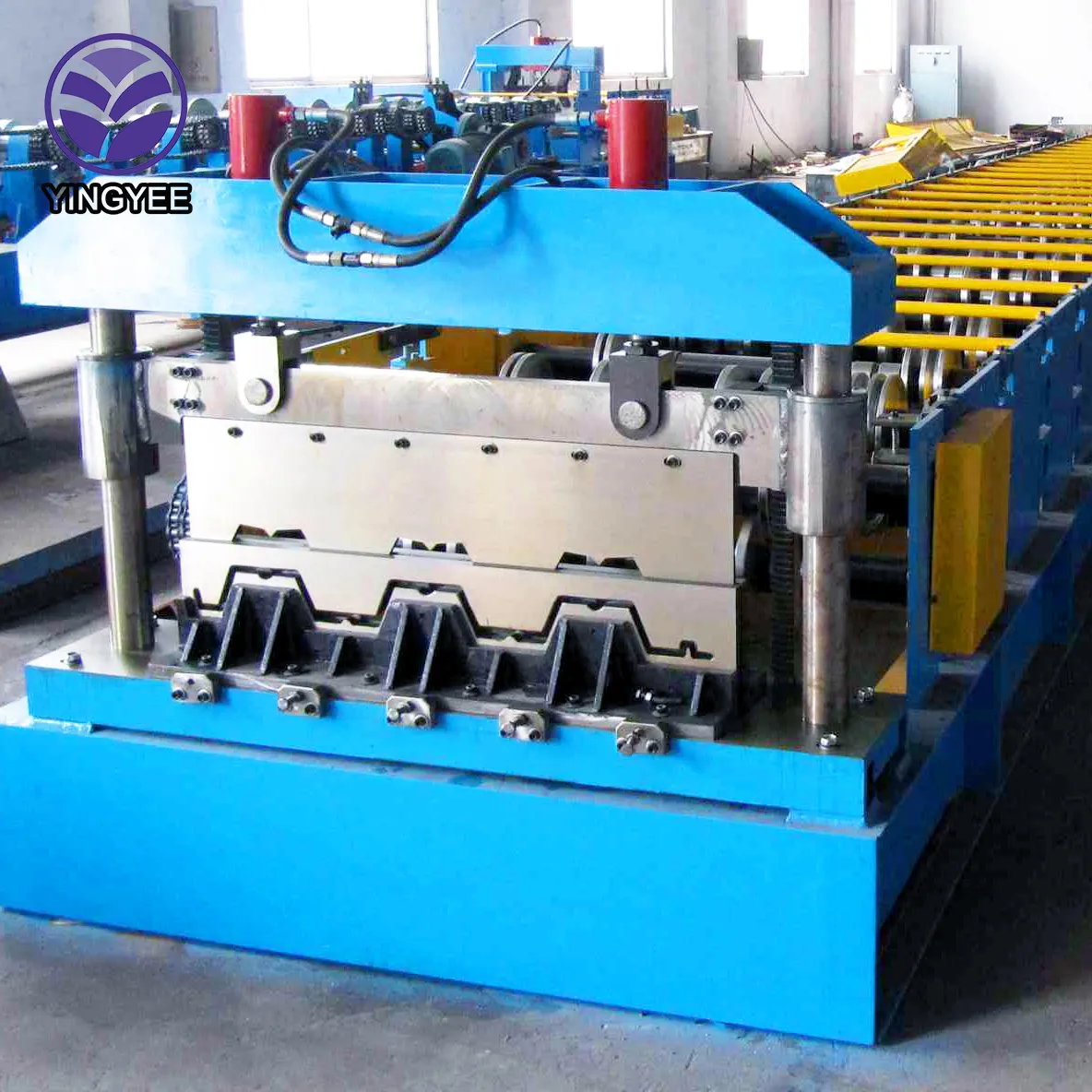

A μηχανή διαμόρφωσης ρολού γωνίας τοίχου is an essential tool in modern construction, providing precision, efficiency, and cost savings. Whether used in curtain wall systems or ceiling structures, this machine ensures high-quality production with minimal material waste. For businesses looking for a wall angle roll forming machine for sale, choosing the right model can significantly enhance productivity and profitability.

A curtain wall system requires precise and durable components to ensure structural stability and aesthetic appeal. The μηχανή διαμόρφωσης ρολού γωνίας τοίχου is essential for producing wall angles that provide support and alignment for curtain walls. These angles act as connectors between different parts of the curtain wall, ensuring a strong framework that can withstand environmental pressures.

High-precision forming is crucial in the curtain wall system, as even the slightest deviation in angle size can lead to alignment issues. The μηχανή διαμόρφωσης ρολού γωνίας τοίχου guarantees uniformity in production, reducing the need for manual adjustments and minimizing installation errors. By using a machine that delivers consistency, construction companies can improve efficiency and reduce labor costs. Additionally, with options available from various wall angle roll forming machine manufacturers, businesses can select models that suit their production needs and material preferences.

One of the key concerns in manufacturing is material waste, which directly impacts production costs. A well-designed μηχανή διαμόρφωσης ρολού γωνίας τοίχου incorporates advanced cutting and forming techniques to minimize scrap and optimize material usage. With precise roll forming technology, the machine ensures that every piece of material is efficiently shaped without excessive trimming.

Modern wall angle roll forming machine manufacturers focus on designing machines with automated feeding and cutting systems that optimize the sheet metal’s length and width. This significantly reduces unnecessary offcuts, ensuring a higher utilization rate of raw materials. Additionally, machines equipped with intelligent control systems can analyze production data in real time and make adjustments to minimize waste. If you are searching for a wall angle roll forming machine for sale, consider models with high material utilization efficiency to lower costs and increase profitability.

Evaluating the efficiency of a μηχανή διαμόρφωσης ρολού γωνίας τοίχου is essential for optimizing production planning. The calculation method for production efficiency typically involves factors such as forming speed, raw material usage, and downtime.

To determine the efficiency of your μηχανή διαμόρφωσης ρολού γωνίας τοίχου, consider the following formula:

Production Efficiency (%) = (Actual Output / Theoretical Output) × 100

The actual output is the number of finished wall angles produced, while the theoretical output is based on the machine’s rated forming speed and material feed rate. By monitoring this efficiency rate, manufacturers can identify areas for improvement, such as reducing setup time, optimizing material selection, and maintaining the machine for consistent performance. Some wall angle roll forming machine manufacturers provide software integration for real-time efficiency tracking, helping businesses maintain peak productivity.

The choice of wall angle roll forming machine material plays a significant role in ensuring durability and functionality. High-quality galvanized steel, stainless steel, and aluminum are commonly used materials, each offering unique benefits. Galvanized steel provides corrosion resistance, making it ideal for humid environments. Stainless steel offers superior strength, while aluminum is lightweight and easy to install.

When choosing a μηχανή διαμόρφωσης ρολού γωνίας τοίχου, it is essential to ensure compatibility with different materials. Some advanced machines are designed to handle multiple material types, giving manufacturers flexibility in production. Additionally, certain wall angle roll forming machine manufacturers offer customization options, allowing businesses to select machines tailored to their specific production needs.

When looking for a wall angle roll forming machine for sale, consider factors such as forming speed, automation level, material compatibility, and after-sales support from the manufacturer. Investing in a high-quality machine ensures long-term productivity and cost savings.

A μηχανή διαμόρφωσης ρολού γωνίας τοίχου enhances efficiency by automating the forming process, reducing manual labor, and ensuring precise and consistent output. Advanced models feature real-time monitoring and automatic adjustments to optimize performance.

High-quality wall angle roll forming machine material ensures durability, corrosion resistance, and structural integrity. Choosing the right material enhances the longevity and reliability of the wall angles produced.

Reliable wall angle roll forming machine manufacturers provide superior build quality, advanced technology, and excellent customer support. Choosing a reputable manufacturer ensures that you receive a durable and efficient machine with comprehensive service options.

Yes, many wall angle roll forming machine manufacturers offer customization options to meet specific production requirements. Customization can include specialized cutting mechanisms, additional automation features, and material compatibility adjustments.

By investing in a high-quality μηχανή διαμόρφωσης ρολού γωνίας τοίχου, businesses can significantly improve efficiency, reduce waste, and produce consistent, high-quality wall angles for various applications.