Knudson rollforming technology has revolutionized the manufacturing industry by offering an efficient and versatile solution for creating complex shapes and profiles from metal sheets. The technology, named after its pioneer, stands as a testament to innovation and precision in metal fabrication. Rollforming has become pivotal in sectors such as construction, automotive, and aerospace, renouncing the traditional methods that were less efficient and more labor-intensive.

Knudson's legacy in rollforming is founded on decades of engineering expertise and a relentless pursuit of quality. Their machinery is renowned for its durability and precision, capable of processing a variety of metals including aluminum, steel, and copper, which allows companies to produce components tailored to client specifications while maintaining the integrity of the material. The adaptability of Knudson rollforming machines makes them indispensable tools for manufacturers seeking to bolster production efficiency and product quality.

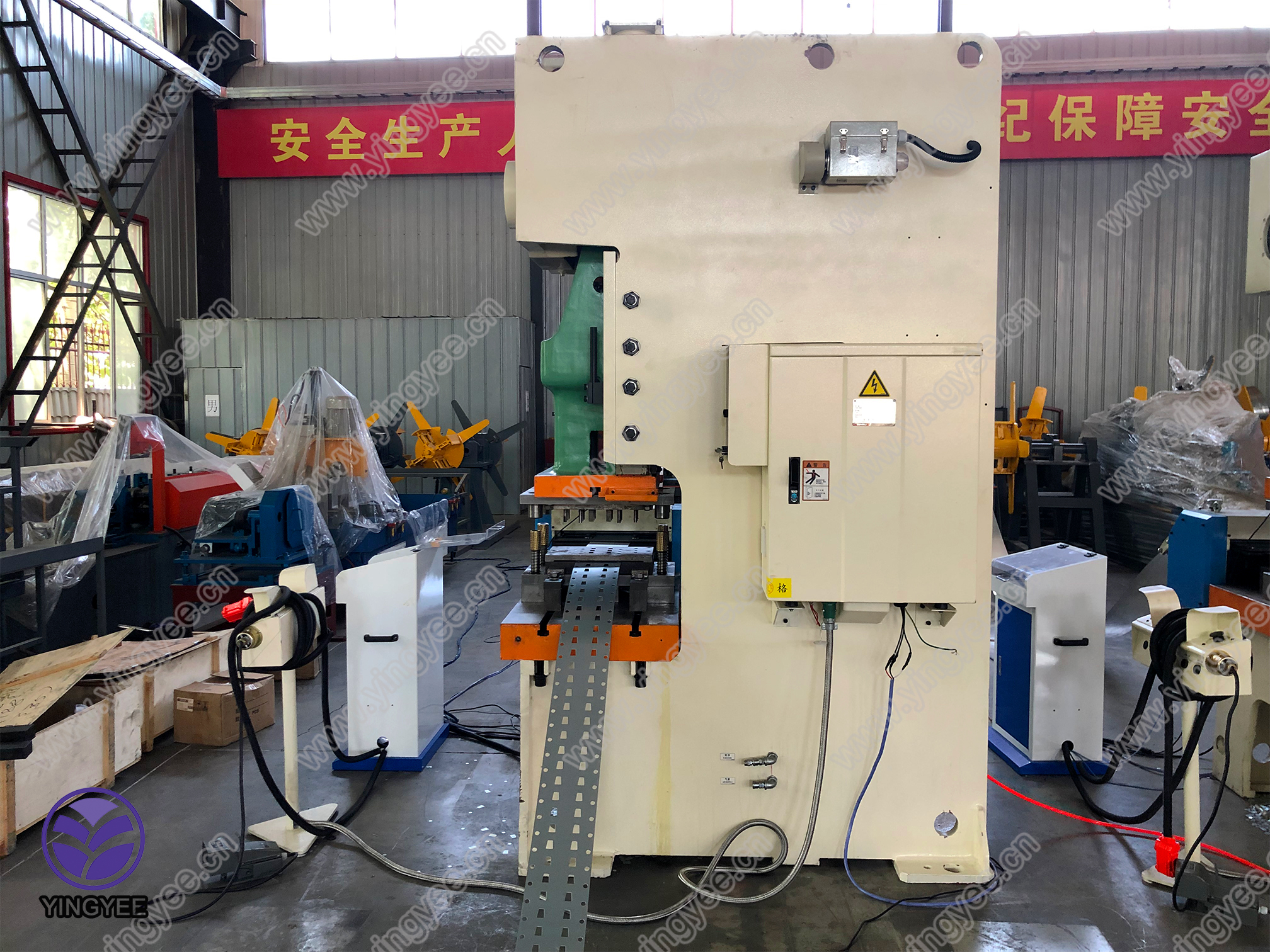

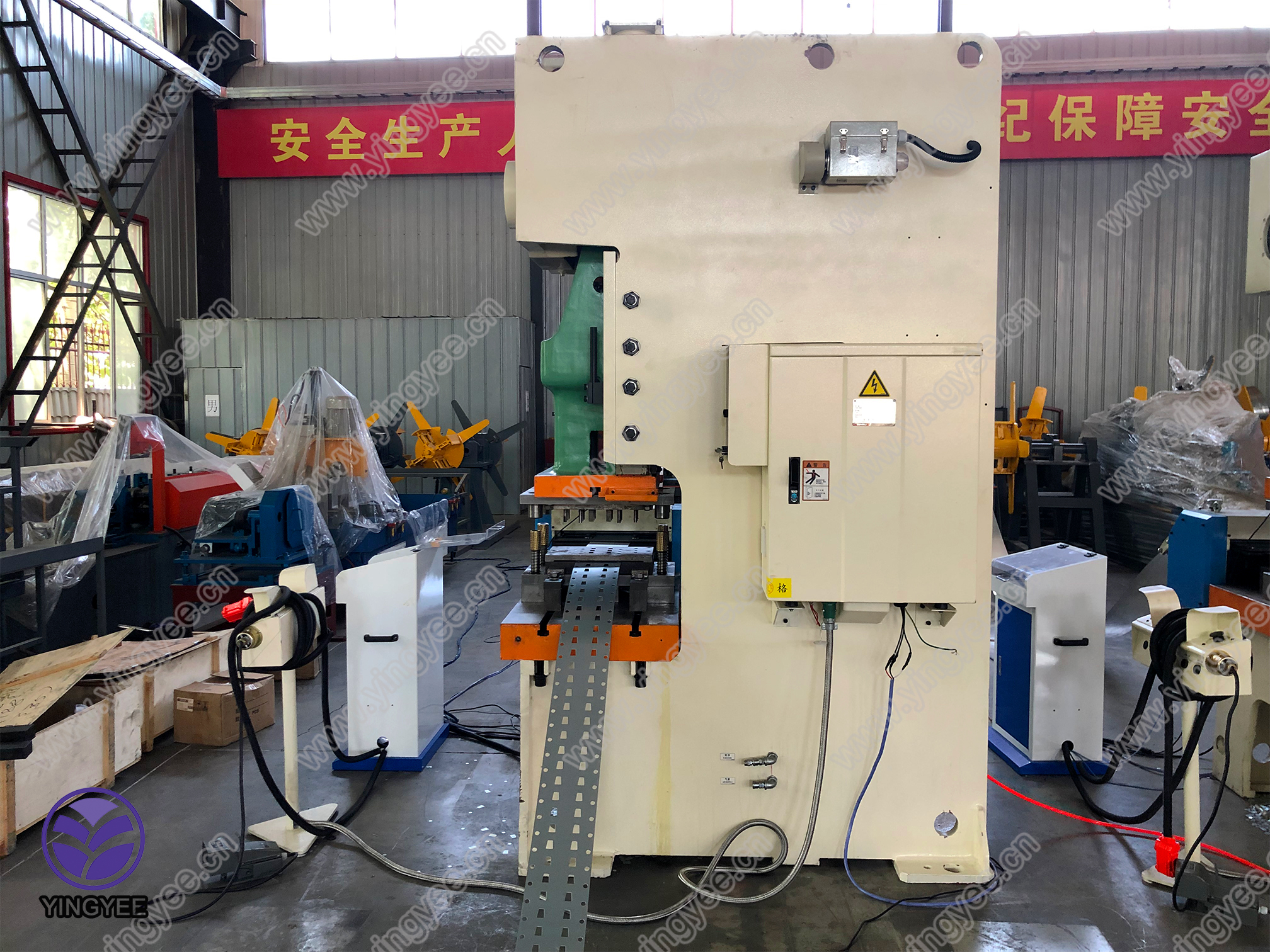

Expertise in rollforming requires understanding the nuances of material properties and the mechanical intricacies involved in shaping them. Knudson machines incorporate advanced features such as automated material feeding systems, precision cutting tools, and customizable roll sets, which ensure that each production run meets specific design requirements with minimal human intervention. This level of automation not only speeds up the production process but also minimizes human error, resulting in a consistently high-quality output.

The authoritativeness of Knudson rollforming machines is established through certifications and compliance with international manufacturing standards. Regular innovation and updates in technology ensure that their equipment is at the forefront of the industry. By maintaining strict adherence to standard operating procedures and quality control measures, Knudson solidifies its reputation as a leader in the rollforming machinery sector. Their commitment to sustainability is reflected in eco-friendly practices and the ability to reduce waste through precise material cutting and forming.

Trustworthiness in the production process is crucial for manufacturers relying on rollforming as a core component of their operations. Knudson has built a network of authorized service centers and offers extensive warranty options to enhance trust and provide peace of mind to their customers. In addition to robust customer support, they supply comprehensive training for operators, ensuring that each machine is utilized to its full potential and downtime is minimized.

knudson rollforming

The real-world applications of Knudson rollforming are vast and varied, reflecting the technology’s versatility. In the construction industry, rollformed products are essential for creating structural components, roofing, and cladding systems that are both durable and aesthetic. Automotive manufacturers utilize rollforming for crafting trim, window frames, and chassis components, benefiting from precise tolerances and the lightweight strength necessary for modern vehicles. Aerospace sectors leverage these machines for fabricating cabin parts and structural elements where precision and reliability are non-negotiable.

In a competitive market, the efficiency gains that Knudson rollforming provides can mean the difference between success and failure. By reducing production times and improving the consistency of the output, manufacturers who adopt this technology naturally position themselves ahead of competitors. The lower operating costs and reduced material waste translate into an improved bottom line, while the scalable nature of Knudson's machinery allows businesses to expand their operations without significant reinvestment.

A critical factor in the success of any manufacturing technology is its ability to evolve with industry demands. Knudson has demonstrated a clear vision for the future, investing in research and development to explore new possibilities in rollforming. Emerging technologies such as IoT integrations and smart manufacturing practices are being harnessed to augment capabilities, leading to smarter, more connected factories where data-driven decisions optimize production.

For companies looking to leverage the full potential of metal fabrication, Knudson rollforming is not merely a tool but an integral component of a modern manufacturing strategy. By choosing Knudson, manufacturers align themselves with a partner that embodies experience, expertise, and an unwavering dedication to quality and innovation. In an era where efficiency and precision cannot be overstated, Knudson rollforming stands as a beacon of technological prowess and reliability.