Navigating the Intricacies of C-Shaped Steel Roll Forming Machines A Deep Dive into Their Expert Usage and Benefits

C-shaped steel roll forming machines have emerged as quintessential tools in the realm of metal fabrication, providing unparalleled efficiency and precision in shaping steel components for a myriad of applications. As industrial demands evolve, the reliability, speed, and accuracy of these machines have cemented their status as indispensable assets within manufacturing industries. Through the lens of experience, expertise, authoritativeness, and trustworthiness, we explore the multifaceted advantages of these machines and their transformative impact on steel fabrication processes.

Experience has shown that the C-shaped steel roll forming machine stands out due to its versatility in crafting uniform steel profiles with high structural integrity. Drawing from years of hands-on engagement in the metalworking sector, professionals consistently encounter the machine's ability to deliver precision outputs while minimizing wastage. This efficiency is a game-changer for large-scale projects where material cost management is critical. Users frequently attest to how seamlessly these machines integrate into existing manufacturing lines, thanks to their user-friendly interfaces and adaptable design.

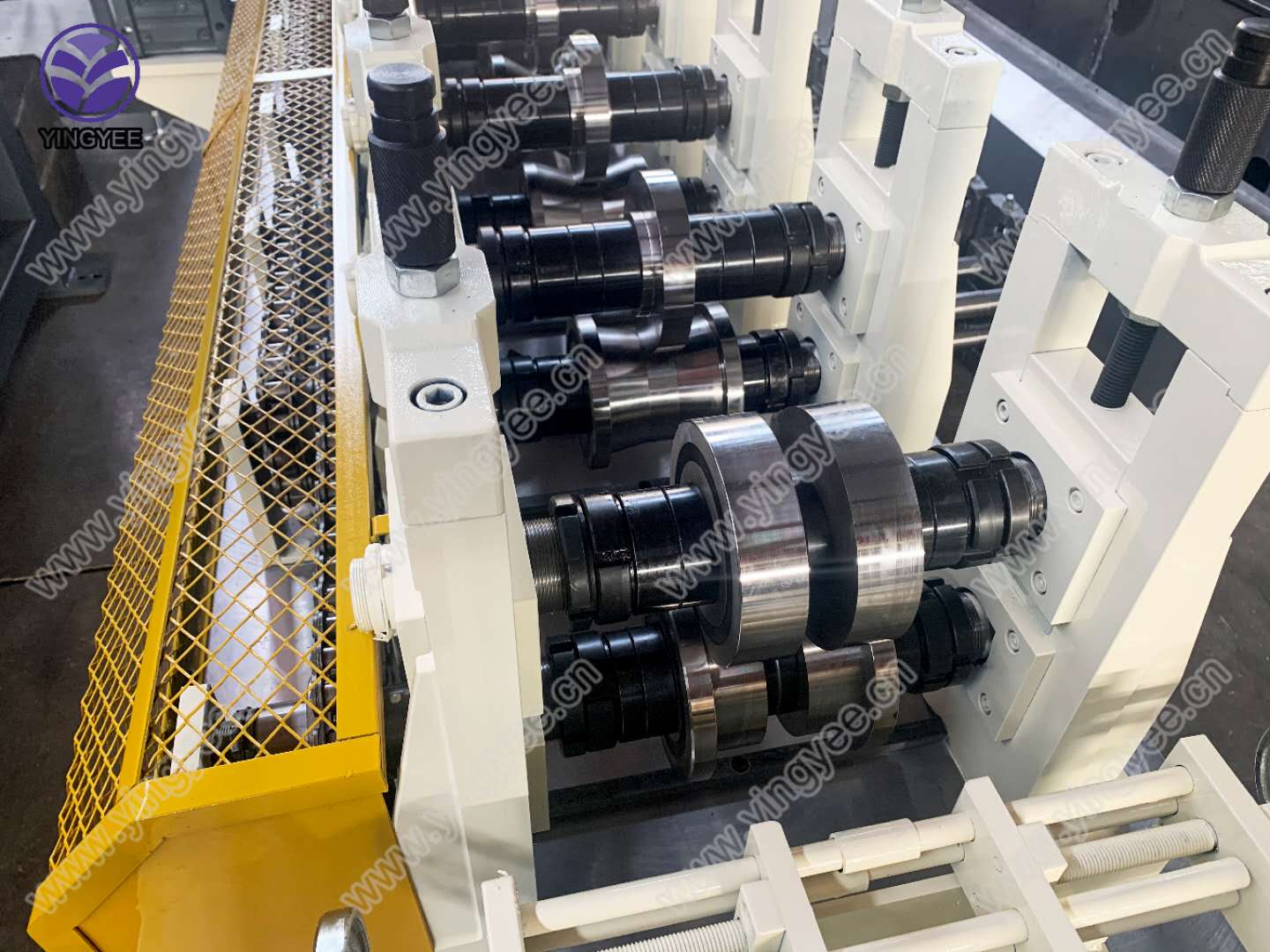

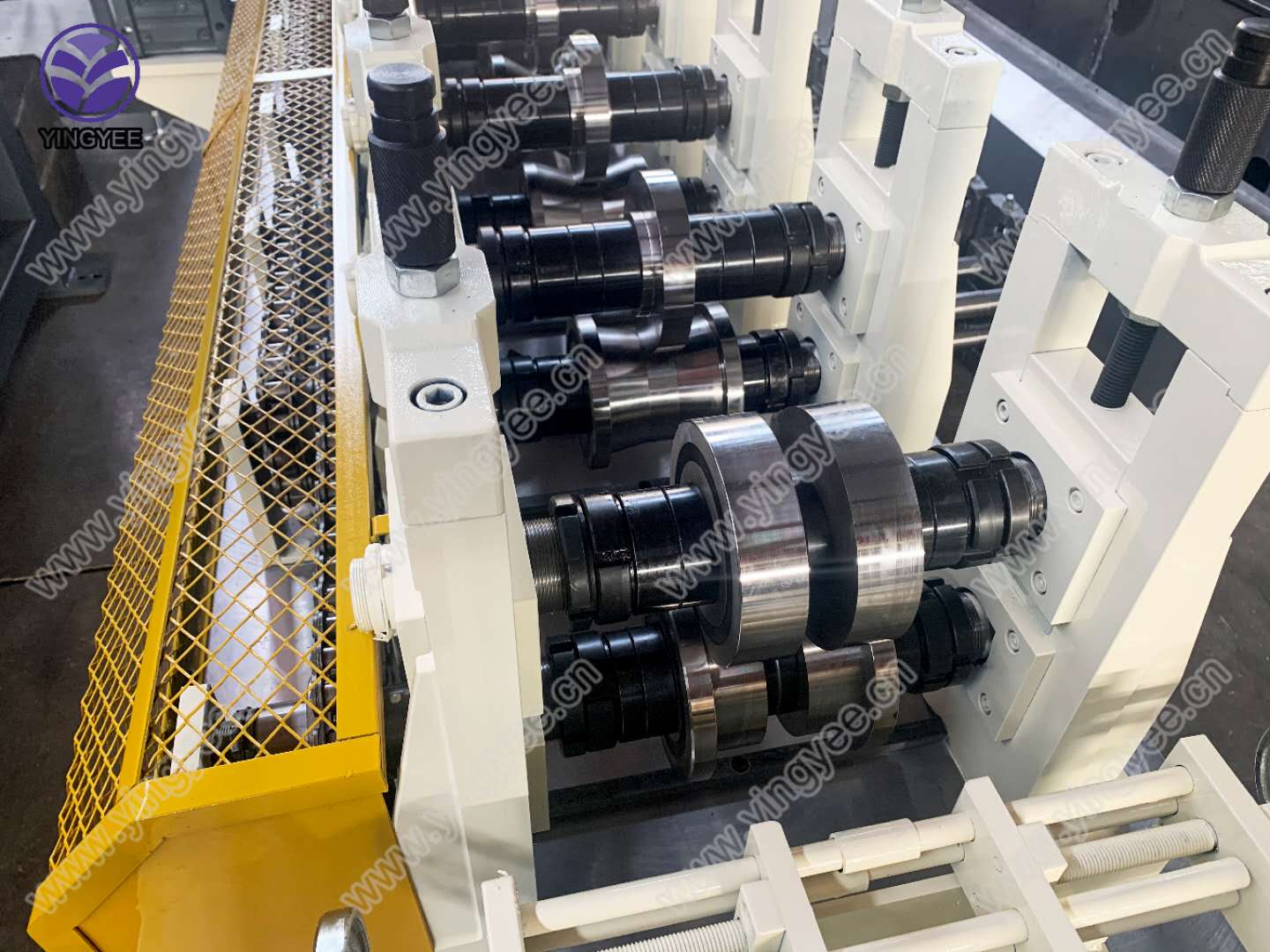

Expertise in utilizing C-shaped steel roll forming machines is crucial for optimizing their performance and achieving desired output qualities. The machines operate through a series of meticulously calibrated rollers that press and shape metal sheets into C profiles. Masterful control over the roll forming process requires an in-depth understanding of variables such as material properties, roller geometry, and machine tempo. Skilled operators leverage their technical know-how to adjust these parameters, ensuring that each steel profile meets stringent industry standards and client specifications. Furthermore, ongoing training and certification programs are integral in equipping operators with cutting-edge techniques and troubleshooting skills, thereby enhancing the overall productivity of manufacturing units.

c shaped steel roll forming machine

The authoritativeness of C-shaped steel roll forming machines in the metal fabrication industry is evidenced by their widespread adoption and endorsement by leading manufacturers worldwide. These machines are engineered to comply with rigorous international quality and safety standards, underscoring their credibility and reliability. Industry conventions and trade expos frequently showcase advancements in roll forming technology, reaffirming the machines' relevance and authority. Additionally, collaborations between machine manufacturers and academic institutions lead to continuous innovations, further establishing these machines as leaders in their field.

Trustworthiness in C-shaped steel roll forming machines is built on a foundation of consistent performance and robust construction. Manufacturers are committed to using high-grade materials to ensure the machines can withstand the demanding conditions of industrial environments. Regular maintenance protocols and vendor support systems bolster the machines' dependability, offering users peace of mind regarding operational continuity. Testimonials from longstanding users of these machines highlight a track record of minimal downtime and extended lifespan, solidifying their reputation as a reliable investment.

In sum,

the role of C-shaped steel roll forming machines in modern manufacturing cannot be overstated. Their ability to transform raw metal into precise structural components efficiently underpins a wide range of infrastructure, automotive, and construction projects globally. By emphasizing the experiential insights, professional expertise, authoritative validation, and trustworthiness associated with these machines, manufacturers are better positioned to harness their full potential for advancing industrial capabilities. As technology progresses, these versatile machines continue to adapt, promising future innovations that will further streamline steel fabrication processes and expand the possibilities within metalworking industries.