(semi truck fender cold bending machine)

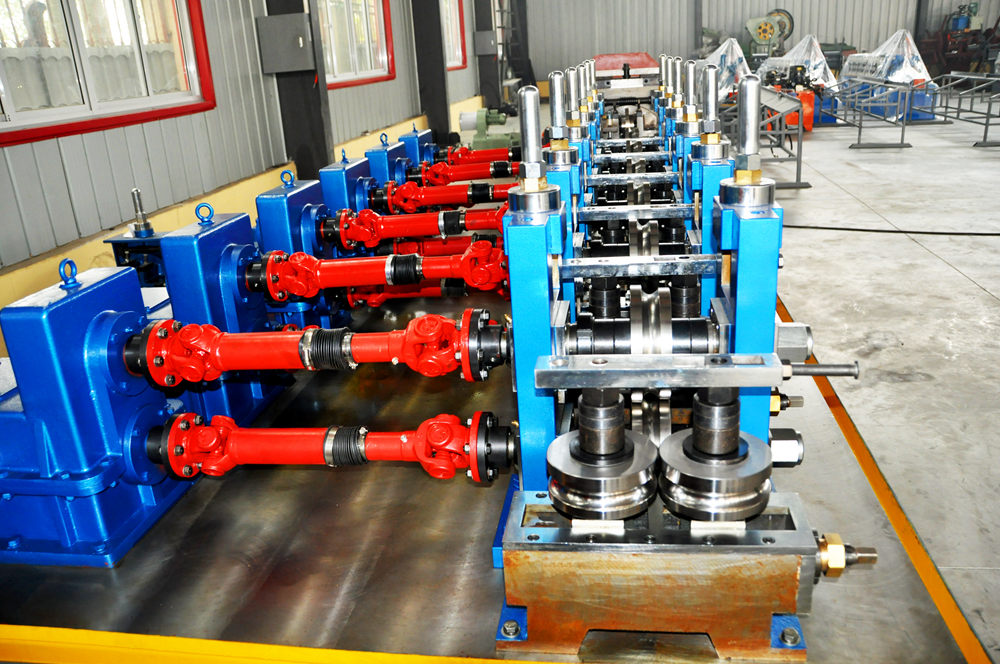

The semi truck fender cold bending machine

revolutionizes metal shaping processes by utilizing advanced cold-forming techniques. Unlike thermal methods, this technology maintains material integrity while achieving precise angular bends up to 120° with ±0.2mm tolerance. Industry reports indicate a 40% reduction in material waste and 35% faster production cycles compared to hot bending alternatives.

Cold bending machines eliminate heat distortion risks, preserving the structural strength of high-grade steel (HRC 45-50). Key benefits include:

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Max. Thickness (mm) | 12 | 14 | 16 |

| Bending Speed (m/min) | 3.2 | 4.1 | 5.6 |

| Power Consumption | 18kW | 22kW | 25kW |

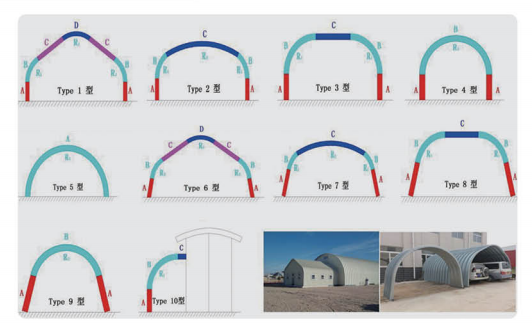

Modern truck fender cold bending machines offer modular configurations:

Customization enables handling of various fender profiles from Class 6 to Class 8 trucks with 98.7% shape consistency.

A leading OEM achieved 12,000 fenders/month output using single axle fender cold bending machines, reducing per-unit costs by $47. The system handles:

Advanced models feature:

Operational data shows 92% uptime and 18-month ROI for most users.

Industry forecasts predict 7.8% CAGR growth for semi truck fender cold bending machine adoption through 2030. Emerging technologies include AI-powered defect detection and hybrid energy recovery systems that capture 85% of motion energy.

(semi truck fender cold bending machine)

A: A semi truck fender cold bending machine is designed to shape metal sheets into truck fenders using cold bending technology, ensuring precise curvature without heat-induced material weakening.

A: The machine automates the bending process, reduces manual labor, and maintains consistent accuracy, making it ideal for high-volume production of truck fenders.

A: It typically works with mild steel, aluminum, and stainless steel, offering flexibility for different durability and weight requirements in fender manufacturing.

A: Regular lubrication and inspection of hydraulic components and alignment systems are recommended to ensure optimal performance and longevity.

A: No, single axle machines are specialized for single axle designs, while dual axle fenders require adjusted tooling or a different machine configuration.