The electrical junction box making machine is an essential tool for manufacturers in the electrical industry. This specialized machine is designed to produce high-quality electrical junction boxes, which are crucial components in wiring systems, providing safe housing for electrical connections. With the rise in demand for safer and more efficient electrical systems, the need for reliable and consistent production of junction boxes has never been higher.

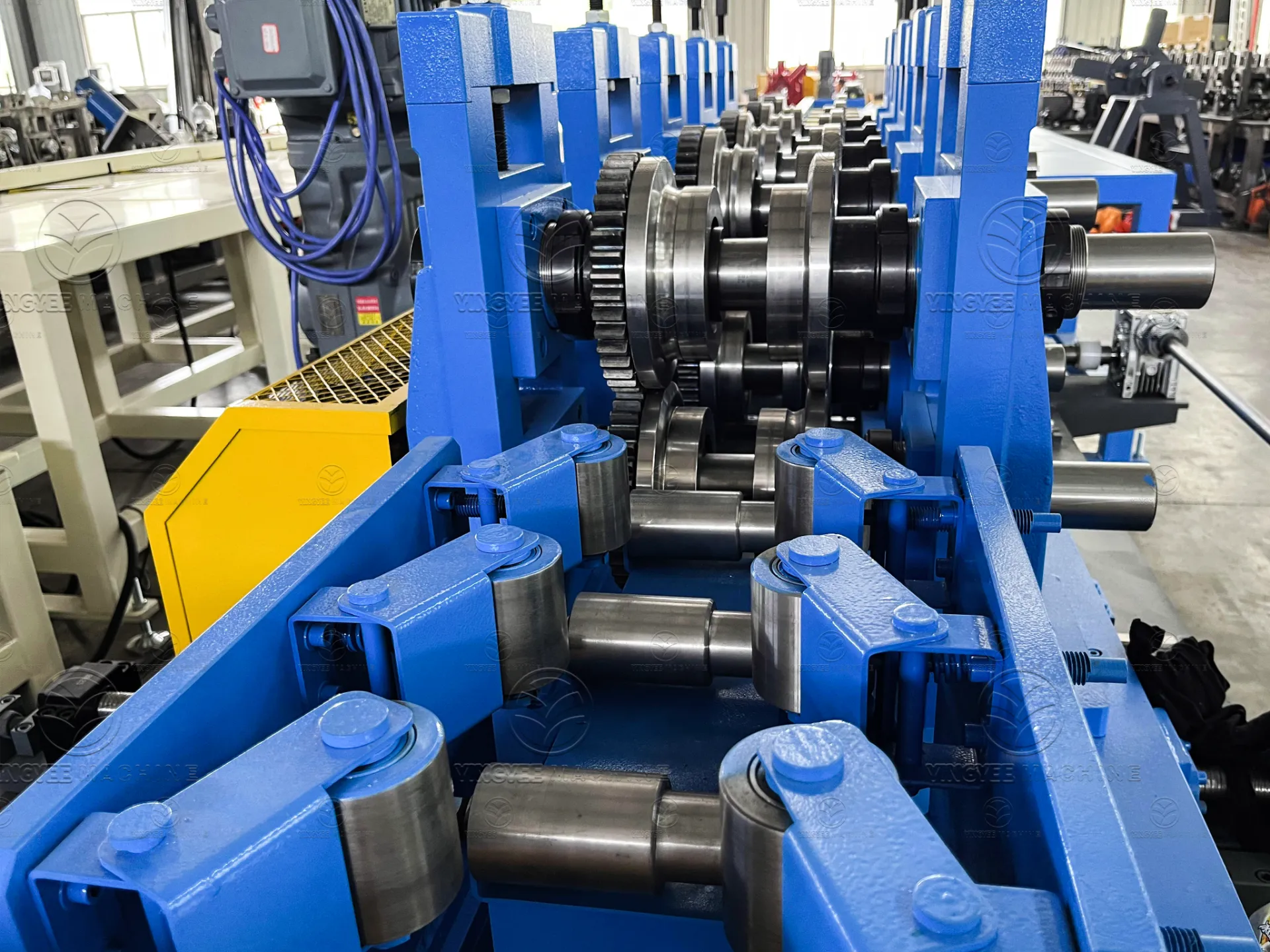

Manufacturers of electrical products rely on the electrical junction box making machine for its precision and speed. This machine automates the process of cutting, bending, and shaping metal sheets into the desired box shapes, which can then be used for a wide range of electrical applications. By using an electrical junction box making machine, manufacturers can improve the consistency of their products, reduce labor costs, and increase overall production efficiency.

Moreover, the electrical junction box making machine minimizes the risk of human error, ensuring that every box meets strict quality standards. The precision of the machine allows for tight tolerances and perfect fitting, which is essential in the production of electrical junction boxes where safety and reliability are paramount. This makes the electrical junction box making machine an invaluable investment for companies looking to scale their production while maintaining high-quality standards.

A junction box making machine plays a pivotal role in improving efficiency in the production of electrical junction boxes. Whether you are manufacturing small or large quantities, this machine ensures that each box is consistently produced with minimal manual intervention. The junction box making machine is equipped with advanced features such as automated feeding systems, PLC control, and hydraulic press systems that help streamline the production process.

One of the most significant advantages of a junction box making machine is its automation. The machine is capable of producing junction boxes of various sizes and shapes with high precision and speed. This automation not only reduces labor costs but also significantly lowers the chances of human error, ensuring that every box is produced to the same high standard.

The junction box making machine also provides manufacturers with the flexibility to produce customized junction boxes tailored to the specific needs of their clients. Whether it's a specific size or a unique design, the machine can handle a variety of production requirements, making it a versatile and essential tool for manufacturers in the electrical industry.

The electrical junction box making machine price can vary significantly depending on factors such as machine size, automation level, and customization options. When considering the price, it is essential to evaluate the overall value the machine brings to your production process. While the upfront cost may seem high, the return on investment (ROI) from increased production efficiency, reduced labor costs, and improved product quality can quickly offset the initial investment.

Many manufacturers choose to invest in a high-quality electrical junction box making machine because it provides a long-term solution for meeting growing demand. The durability and reliability of these machines mean that they can handle large-scale production runs without significant downtime or maintenance costs. Additionally, the electrical junction box making machine price often includes support services, such as installation, training, and after-sales support, which can help you get the most out of your investment.

It's also important to consider the maintenance costs associated with the electrical junction box making machine price. Machines that are easier to maintain and repair can save manufacturers money in the long run. Look for machines that offer easy access to key components and have a good reputation for reliability and durability.

Junction box making is more than just a manufacturing process—it's about creating safe, reliable, and durable products that meet the needs of modern electrical systems. The process involves cutting, bending, and shaping metal sheets into boxes that will house electrical connections. As demand for electrical infrastructure grows, so does the need for high-quality junction boxes that can withstand the demands of both residential and industrial applications.

With junction box making machines, manufacturers can produce boxes that are precisely engineered to meet the specifications of electrical systems. These machines are equipped with advanced technologies such as automatic feeding, precision cutting, and hydraulic forming systems, ensuring that each box is made with minimal waste and maximum accuracy. The ability to automate the process reduces the need for manual labor, helping manufacturers to keep production costs down and enhance operational efficiency.

Moreover, junction box making machines are designed with sustainability in mind. Many machines feature energy-efficient designs that help reduce power consumption, making them a cost-effective solution for manufacturers who want to minimize their environmental impact while maximizing production output. With these machines, manufacturers can meet the growing demand for electrical junction boxes without sacrificing quality or environmental responsibility.

An electrical junction box making machine automates the process of cutting, bending, and shaping metal sheets into electrical junction boxes. These boxes are used to safely house electrical connections and provide reliable protection for electrical systems.

The electrical junction box making machine price can range from $10,000 to $50,000 or more, depending on factors such as size, automation level, and customization options.

A junction box making machine increases production efficiency, reduces labor costs, and ensures consistent product quality by automating the manufacturing process. It also minimizes human error and can produce customized junction boxes for different applications.

Yes, many electrical junction box making machines are capable of handling a range of materials, including galvanized steel, aluminum, and stainless steel, allowing manufacturers to produce junction boxes for various electrical applications.

When choosing a junction box making machine, consider factors such as your production capacity, the materials you need to process, and the level of automation you require. It's also important to evaluate the manufacturer's reputation and after-sales support.