Understanding C-Section and Z-Section Purlin Roll Forming Machines

In the realm of modern construction and manufacturing, various structural components play a crucial role in ensuring the stability and integrity of buildings. Among these components, purlins—specifically C-section and Z-section purlins—are essential for supporting roofs and walls. The efficient production of these components is made possible through advanced technology known as roll forming machines. This article explores the significance, functionality, and applications of C and Z purlin roll forming machines.

What are Purlins?

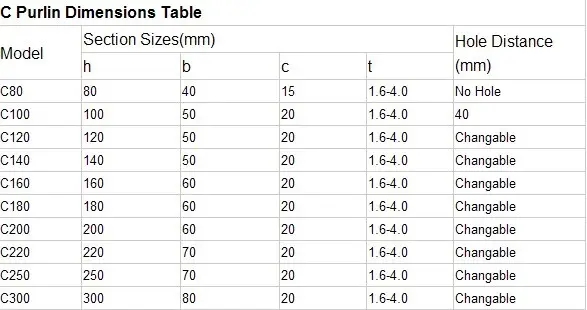

Purlins are horizontal structural members used in roof and wall systems. They provide support to roof sheeting and are typically anchored between vertical supports such as walls or columns. There are two primary types of purlins C-section (or C purlins) and Z-section (or Z purlins). The key difference lies in their shape, which affects their load-bearing capacities and applications.

C purlins feature a ‘C’ shaped cross-section and are ideal for spanning longer distances. They are often used in residential, commercial, and agricultural buildings. Z purlins, characterized by their ‘Z’ shape, provide better overlapping capabilities, making them suitable for applications where greater strength and stability are required.

The Role of Roll Forming Machines

Roll forming machines are specialized equipment designed to produce longitudinally continuous profiles from coiled sheet metal. They work by feeding metal coils through a series of rollers that progressively shape the material into the desired profile—C or Z purlins in this case. The process is efficient, cost-effective, and allows for uniform production of components.

Key Components of Purlin Roll Forming Machines

A typical C/Z purlin roll forming machine consists of several integral components

1. Decoiler This component unwinds the coiled sheet metal to ensure a smooth feeding process into the machine.

2. Roll Forming Station The core part of the machine where multiple rollers shape the metal into C or Z sections. Each roller is precisely designed to incrementally bend the metal at specific angles, allowing for the accurate formation of the purlin.

3. Cutting Mechanism After the purlin reaches the desired length, a cutting mechanism—a shear blade or guillotine—cuts the formed metal profile.

4. Control System Modern roll forming machines come equipped with advanced control systems that allow operators to easily adjust parameters such as speed, length, and alignment, ensuring high precision in production.

5. Support and Output Table Once the purlins are cut, they are deposited onto a support table for further handling, stacking, or packaging.

Applications of C and Z Purlins

C and Z purlins are widely used across various sectors

- Construction Industry They are commonly utilized in the construction of warehouses, factories, and commercial buildings as roofing and wall supports.

- Agricultural Structures C and Z purlins are vital for the construction of barns and sheds, providing durable support against varying weather conditions.

- Renewable Energy These purlins are also found in the frameworks of solar panel installations and wind turbine structures due to their strength and lightweight properties.

Advantages of C/Z Purlin Roll Forming Machines

1. Efficiency Roll forming machines can produce thousands of purlins in a short timeframe, significantly reducing labor costs and lead times.

2. Versatile Production These machines can be easily adjusted to manufacture different profiles, making them suitable for various projects.

3. Material Savings The process typically incurs minimal waste, as the continuous production of profiles maximizes the use of raw materials.

4. High Precision Advanced technology ensures that each purlin is produced with consistent dimensions and shapes, which is crucial for structural integrity.

5. Durability and Quality The roll forming process enhances the mechanical properties of the metal, resulting in sturdy and reliable purlins.

Conclusion

C and Z purlin roll forming machines are integral to modern construction practices, providing versatile, efficient, and high-quality solutions for structural support. As construction demands evolve, the technology behind these machines continues to advance, further enhancing their applications and performance in the industry. By understanding the importance and functionality of purlin roll forming machines, manufacturers can better meet the needs of their clients, ensuring that structures remain safe, stable, and resilient.