Understanding Corrugated Sheet Forming Machines An Overview

Corrugated sheet forming machines play a crucial role in the manufacturing sector, particularly in the production of packaging materials and structural elements. These machines are designed to create corrugated sheets, which are lightweight yet exceptionally strong and versatile. This article will explore the operation, benefits, and applications of corrugated sheet forming machines.

The Operational Mechanism

At the core of a corrugated sheet forming machine is its ability to mold flat sheets of paper or plastic into a wavy structure. The process typically involves several stages, starting with feeding raw materials into the machine. The sheets are then passed through rollers that generate specific patterns of waves or flutes. These fluted sections provide added strength and durability, making corrugated sheets ideal for various applications.

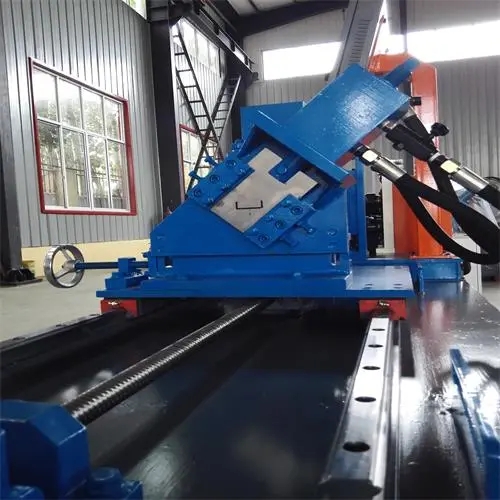

The primary components of these machines include the feeder, forming section, drying section, and cutting unit. The feeder transports the raw material into the forming section, where it's shaped. After forming, sheets enter the drying section, where moisture is removed to ensure longevity. Finally, the cutting unit sizes the sheets according to customer specifications.

Benefits of Using Corrugated Sheet Forming Machines

One of the most significant advantages of using corrugated sheet forming machines is efficiency. These machines can produce large volumes of corrugated sheets in a relatively short period, which is essential for meeting the high demand in industries such as packaging and construction. Moreover, they minimize waste by optimizing the use of raw materials – an essential factor in today’s eco-conscious market.

Another benefit is versatility. Corrugated sheets can be manufactured in various sizes, thicknesses, and materials, allowing manufacturers to cater to a wide range of customer needs. Whether it’s for shipping boxes, protective packaging, or building materials, corrugated sheets are adaptable enough to serve different industries.

Applications Across Industries

The applications of corrugated sheets are manifold. In the packaging industry, these sheets are used extensively to create boxes and containers due to their lightweight and strong structure. E-commerce businesses, in particular, rely heavily on corrugated packaging to ensure that products arrive at their destination undamaged.

In the construction sector, corrugated sheets are used as roofing and walling materials. Their strength and resistance to impact make them an excellent choice for structures exposed to the elements. Moreover, they are often utilized in temporary structures and event venues due to their ease of installation.

Additionally, the use of corrugated sheets in agriculture is gaining popularity. They can serve as protective coverings for crops, and their flexibility allows for various applications in greenhouse construction.

Conclusion

In conclusion, corrugated sheet forming machines are invaluable assets in modern manufacturing. Their ability to produce strong, lightweight products efficiently meets the various needs of industries ranging from packaging to construction. With ongoing advancements in technology, these machines will likely become even more efficient and versatile, adapting to the ever-changing demands of the market. As businesses continue to pursue sustainable practices, the significance of corrugated sheets and the machines that produce them will undoubtedly grow.