The Importance of Coil Slitting Machine Lines in Manufacturing

In the ever-evolving landscape of manufacturing, efficiency and precision play crucial roles in meeting the demands of various industries. One critical component that facilitates these aspects is the coil slitting machine line. This specialized equipment is designed to cut large rolls of metal, typically steel or aluminum, into narrower strips with high accuracy and consistency.

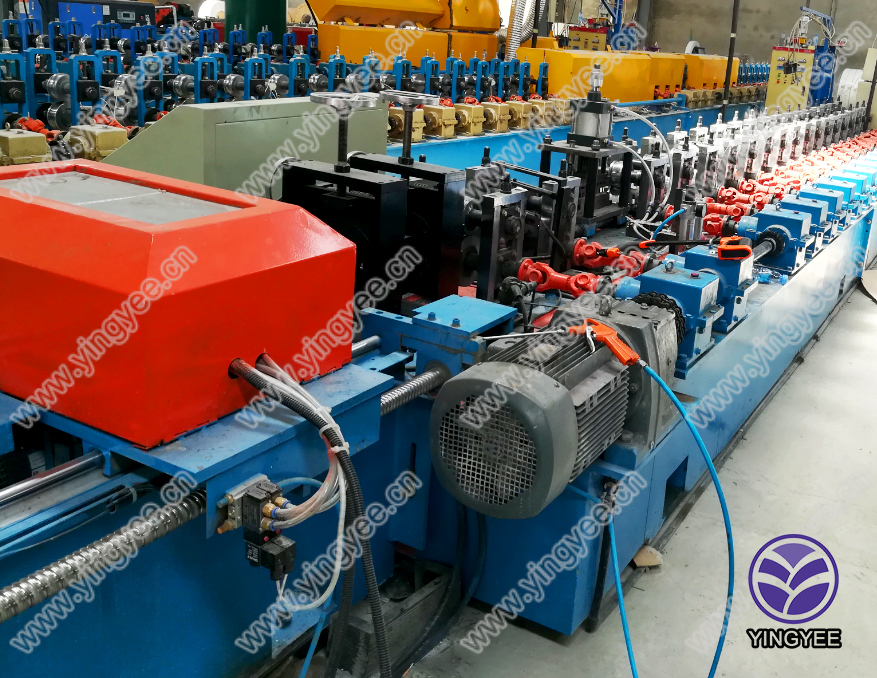

Coil slitting machines offer a variety of advantages, paramount among them being the ability to produce precise cuts without compromising the integrity of the material. The process begins with a large coil being fed into the machine, where it is unwound and passed through rotating knives. These knives shear the coil into specific widths, enabling manufacturers to create products that meet specific application requirements. This level of customization is essential in industries such as automotive, construction, and appliance manufacturing.

Moreover, the coil slitting process significantly enhances productivity. Traditional cutting methods often involve manual labor and additional handling, which can be time-consuming and prone to human error. In contrast, a coil slitting machine line automates these steps, reducing labor costs and streamlining operations. Operators can input precise measurements and specifications, leading to faster turnaround times and higher throughput rates.

Another notable benefit is the reduction of waste materials. With the precision of modern slitting machines, manufacturers can optimize material usage, minimizing excess scrap. This not only contributes to cost savings but also aligns with the industry's growing emphasis on sustainability. By reducing waste, manufacturers not only improve their bottom line but also lessen their environmental impact, making coil slitting machines a more responsible choice in manufacturing practices.

Investment in an advanced coil slitting machine line can also enhance product quality. Modern machines are equipped with advanced features, such as tension control and automated adjustments, ensuring that the strips produced are uniform in thickness and free from defects. This is particularly vital for industries where the quality of materials directly impacts the final product’s performance and reliability.

Moreover, the versatility of coil slitting machine lines cannot be overlooked. They can handle a diverse range of materials and thicknesses, making them suitable for various applications. Whether producing components for the automotive sector or thin strips for consumer electronics, a coil slitting machine line can adapt to different needs, thereby maximizing operational flexibility.

In conclusion, the coil slitting machine line represents a significant asset in the manufacturing process, offering precision, efficiency, and sustainability. As industries continue to evolve and face new challenges, the role of advanced machinery, such as coil slitting machines, will be increasingly vital in driving innovation and maintaining competitiveness. Investing in such technology ultimately paves the way for enhanced productivity and superior product quality, making it an indispensable part of modern manufacturing.