The evolution of technology has transcended traditional manufacturing methods, propelling the industry into an era dominated by automation and precision. In the domain of interior design and construction, the advent of the automatic T ceiling production line marks a significant milestone. This sophisticated machinery is tailor-made for creating T grid ceilings, which are pivotal in modern architecture due to their aesthetic appeal and structural functionality.

A deep dive into the world of automatic T ceiling production lines unveils an ecosystem where intricate machinery, technical expertise, and innovation converge. These lines are engineered for seamless operation, ensuring efficiency and high-quality output. The essence of this production line lies in its ability to automate and streamline the production of ceiling grids, thereby eliminating the labor-intensive aspects of traditional manufacturing while maintaining – if not enhancing – quality standards.

The automatic T ceiling production line incorporates advanced computer numerical control (CNC) technology. CNC systems play a pivotal role in enhancing precision and reducing material wastage, which subsequently translates to cost efficiency. This technology empowers manufacturers to program the machinery with exact dimensions and specifications, guaranteeing that each ceiling T grid is constructed with unparalleled accuracy. Such precision is indispensable when dealing with complex architectural designs that demand strict adherence to spatial constraints.

In the realm of expertise, operators of these machines are often individuals with substantial training in both mechanical engineering and computer programming. Their role is crucial in overseeing the production process, making real-time adjustments, and ensuring that the machinery operates at optimal levels. The likelihood of errors diminishes significantly with automated lines, as these systems are equipped with sensors and feedback mechanisms that promptly detect and rectify anomalies.

Manufacturers that invest in automatic T ceiling production lines do so with an eye on maintaining their competitiveness in a fast-evolving market. The production line’s capability to produce at scale without compromising quality offers an edge, especially in large-scale projects where time is of the essence. Its integration into production facilities speaks to a commitment to modernization and a forward-thinking approach to manufacturing.

From an expertcraft viewpoint, the benefits of deploying automatic T ceiling production lines are manifold. These systems are adaptable, catering to various production requirements by accommodating different materials and designs. This flexibility is key in a market where customization and bespoke solutions are increasingly sought. Moreover, automated lines mitigate the risk of human error, thereby ensuring consistency in product quality – a non-negotiable in high-stakes commercial projects.

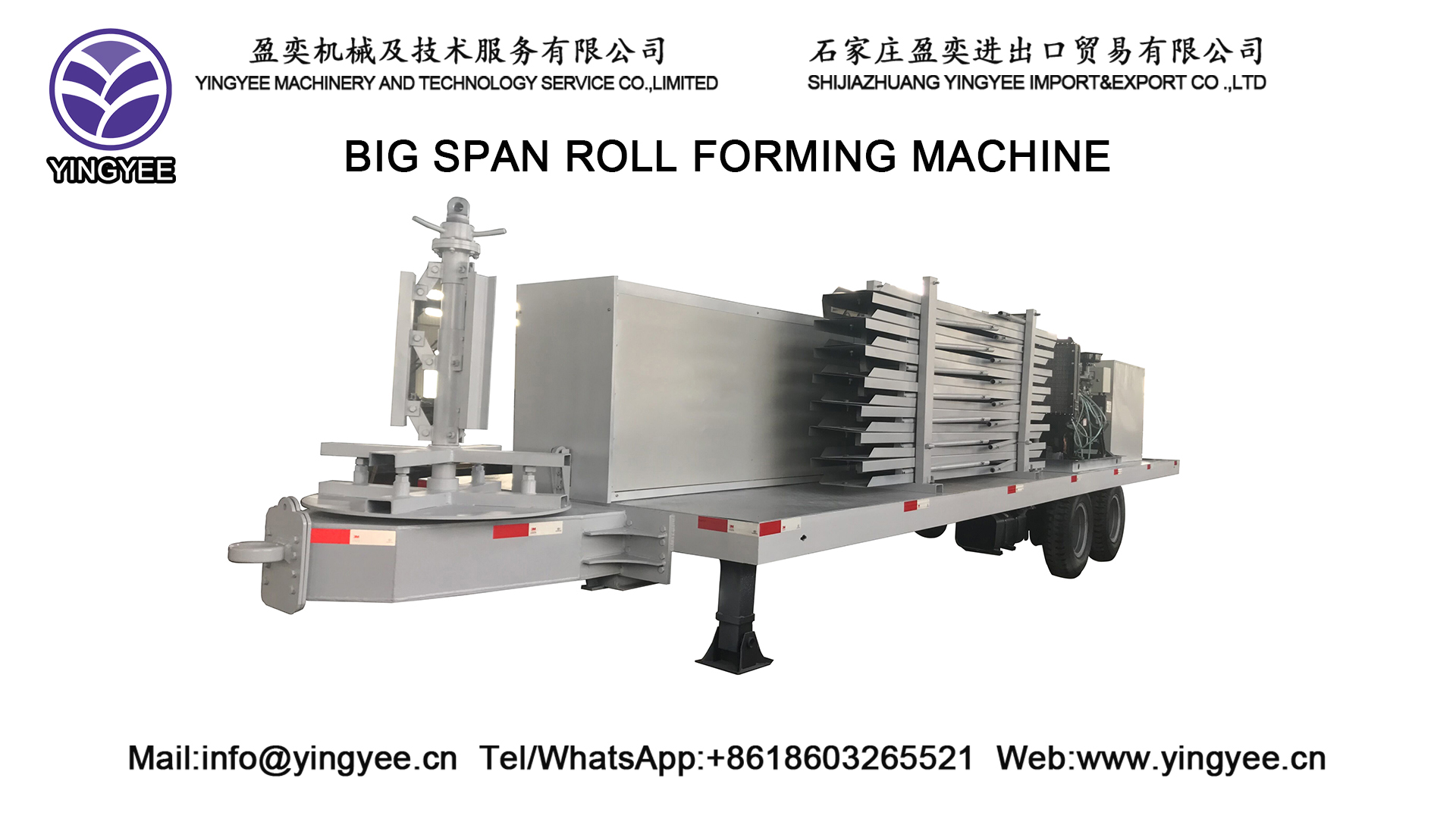

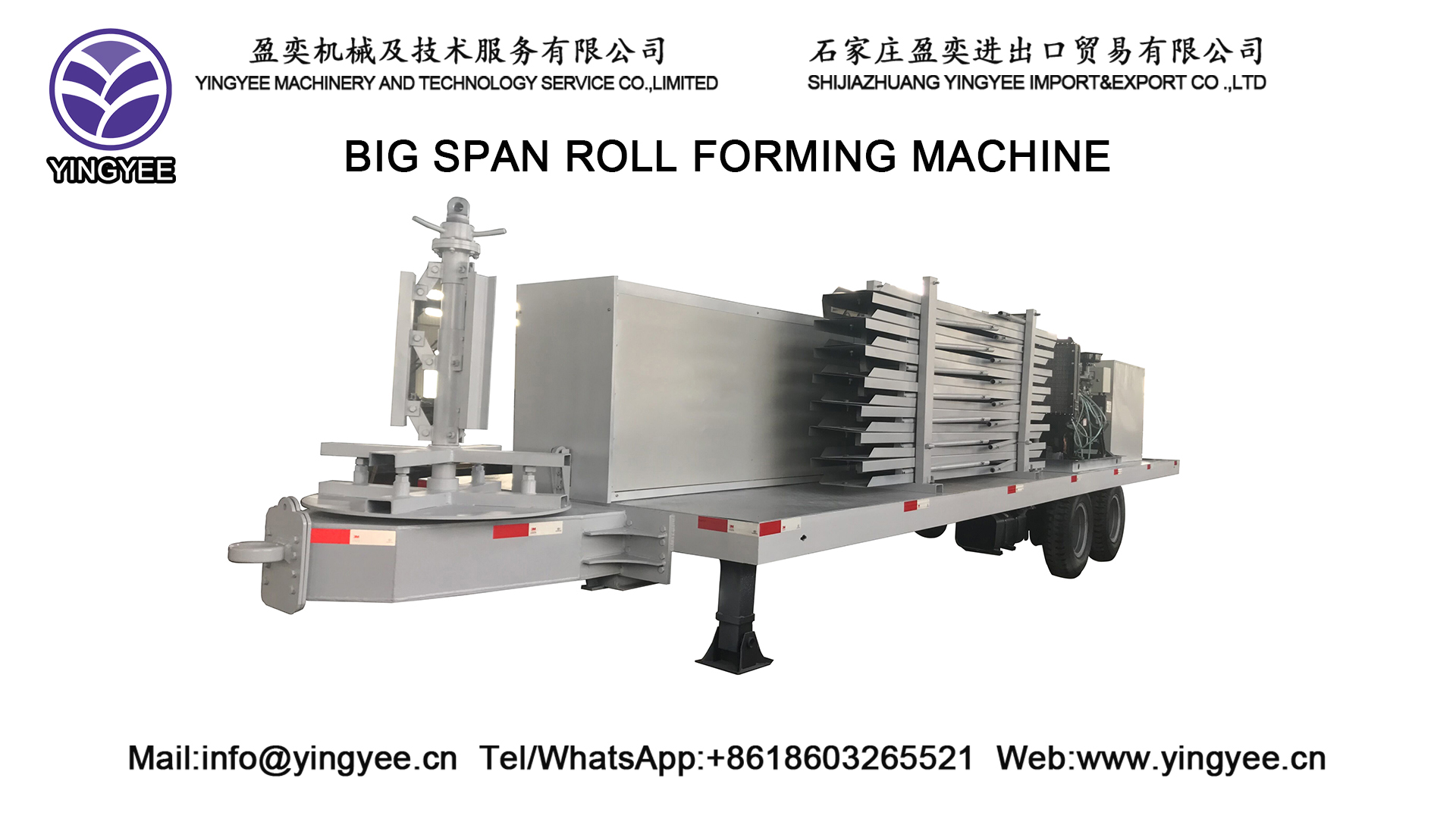

automatic t ceiling production line

The authoritative stature of automatic T ceiling production lines is reinforced by their track record. Producers employing these lines often cite improved output rates of up to 60%, aligning with international standards of manufacturing excellence. Such statistics are testament to their reliability and sustained performance under demanding conditions.

Trustworthiness, the cornerstone of this manufacturing marvel, is engrained in its design and operational framework. With rigorous quality control measures and adherence to international safety standards, these production lines assure stakeholders of their dependability. Clients are assured of timely delivery and product integrity, aspects that are critical in building long-term business relationships.

Investing in automatic T ceiling production lines is not merely an acquisition of advanced machinery; it symbolizes a holistic approach to modern manufacturing, underscored by a commitment to quality and efficiency. As the architectural landscape continues to evolve, the importance of these production lines will only magnify, meeting the higher demands for sustainability, precision, and innovation.

The ongoing advancements in automation technology promise further enhancements to these production lines. Future iterations are expected to incorporate artificial intelligence and machine learning elements, further enhancing their capabilities. These technological integrations are anticipated to result in even greater efficiency and adaptability, setting new benchmarks for the construction and manufacturing industry.

In conclusion, the automatic T ceiling production line represents a harmonization of experience, expertise, authority, and trust within the manufacturing sector. Its introduction and continual evolution offer a glimpse into the future of industrial production, where precision and efficiency are not just goals but standards.