In the world of roofing technology, the trapezoid roof sheet roll forming machine stands out as a revolutionary tool that transforms the way modern construction projects approach roofing. For construction professionals and companies aiming to find the perfect balance between efficiency, quality, and cost-effectiveness, this machine represents not only an investment in technology but also a gateway to superior engineering practices.

When it comes to firsthand experience with these machines, industry experts have observed a leap in productivity and precision.

Imagine a tool that is capable of producing consistently perfect trapezoidal roofing sheets, tailored to specific project needs, with minimal waste. This is exactly what a trapezoid roof sheet roll forming machine achieves. The precision-engineered capabilities allow for exact measurements and cuts, drastically reducing the time and labor traditionally associated with roofing tasks. This shift means that projects are completed not only on time but often ahead of schedule, a vital consideration for construction managers juggling multiple timelines.

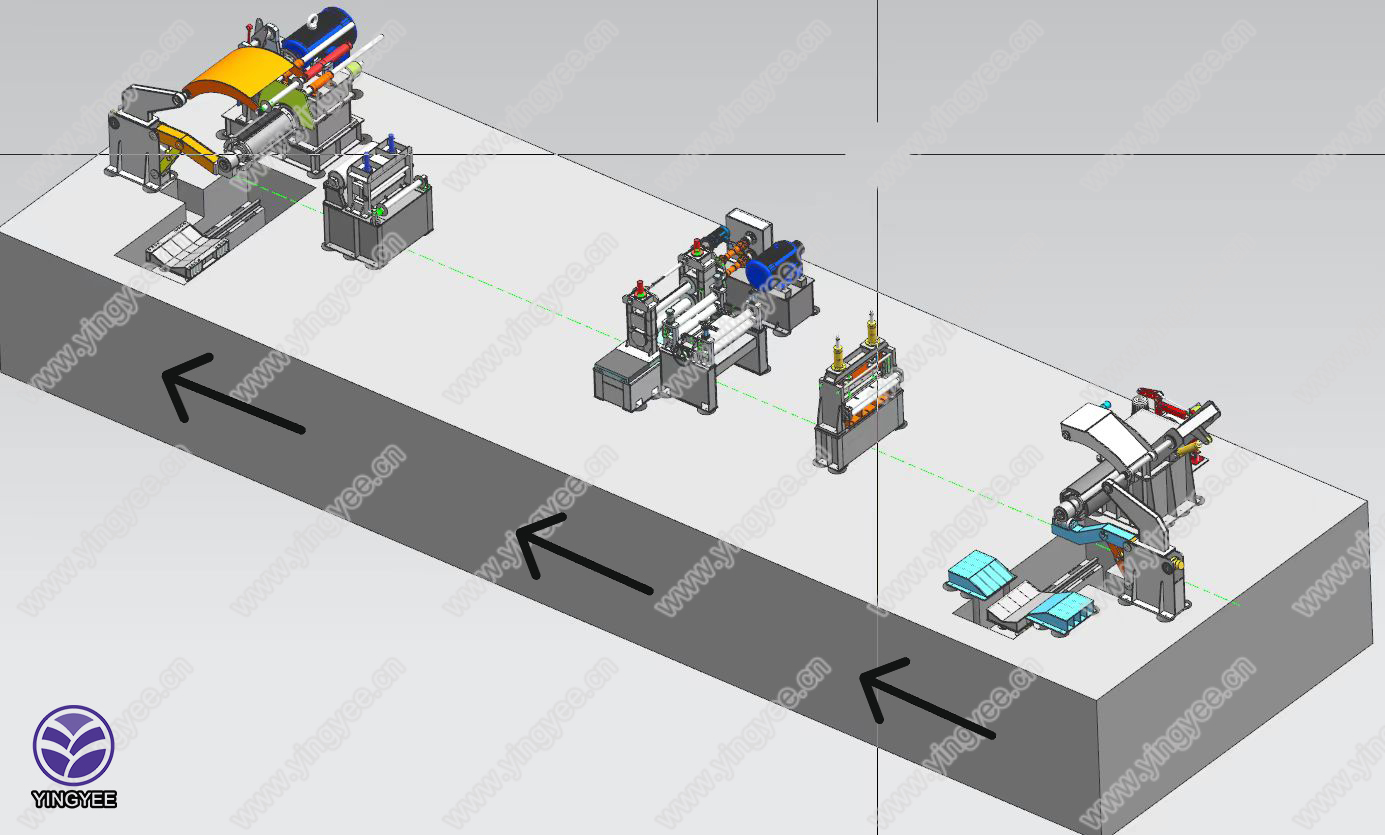

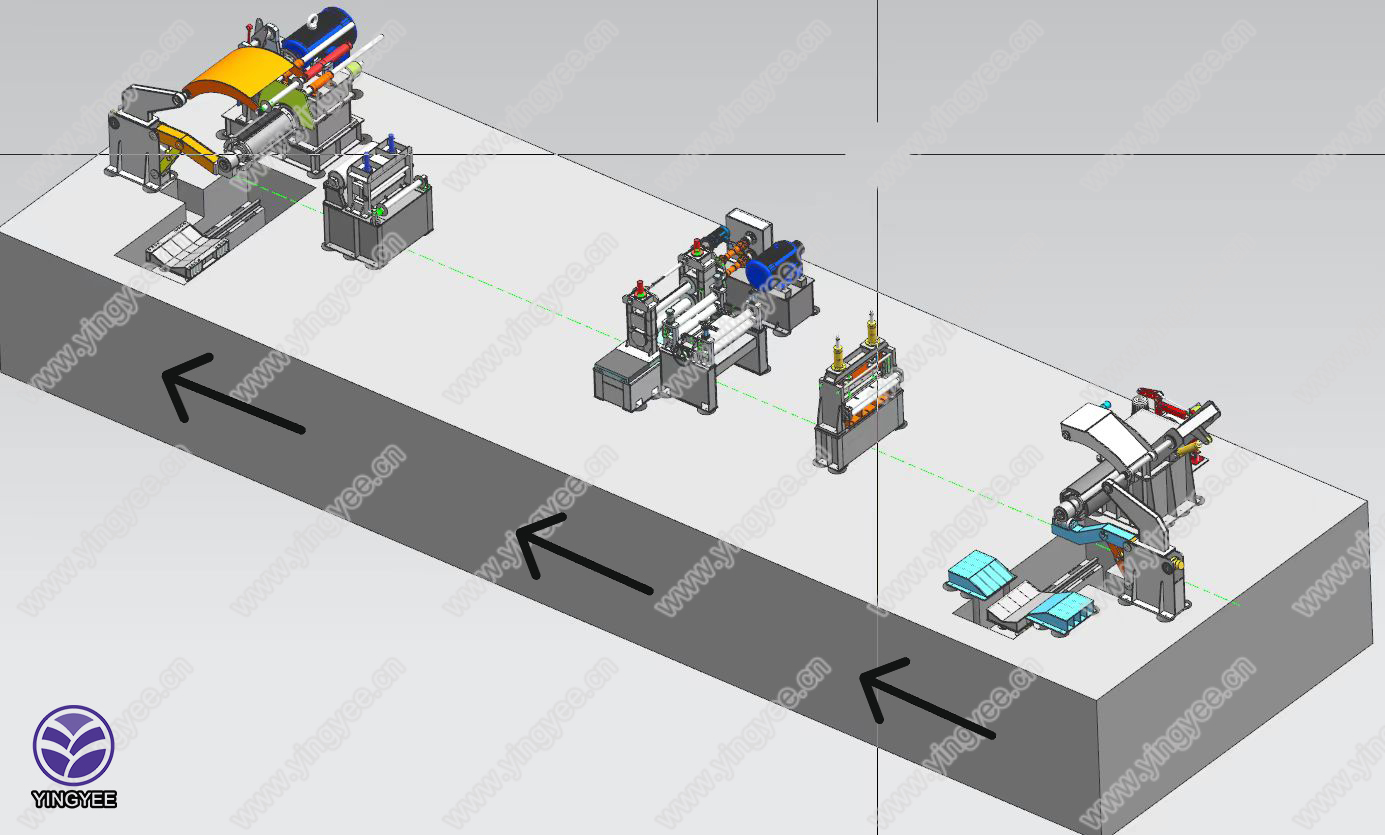

Diving deeper into the expertise surrounding these machines reveals that they are intricately designed with modern engineering principles. The roll forming process involves feeding coils of metal through stationary rollers, shaping the metal precisely into the desired profile. This methodology is rooted in precision mechanics, a field that demands ongoing learning and skill refinement. As such, operators of these machines are highly trained in metallurgy and machining, ensuring every output meets stringent industry standards.

trapezoid roof sheet roll forming machine

Authoritativeness in the context of trapezoid roof sheet roll forming machines comes from the manufacturers who devote significant resources to research and development. Leading companies in this sector adhere to rigorous testing and certification processes, often surpassing ISO and other international standards. By leveraging cutting-edge CAD/CAM technology and automation, these manufacturers provide robust solutions that are customizable to different specifications. This ensures that the roofing materials produced not only fit seamlessly with architectural designs but also withstand environmental stressors such as wind, rain, and extreme temperatures.

Trustworthiness in the industry is illustrated through a track record of reliability and successful project implementations. Construction firms utilizing trapezoid roof sheet roll forming machines report marked improvements in project delivery times and client satisfaction. The machines themselves, constructed from durable materials and built to last, require minimal maintenance, leading to reduced downtime and lower operational costs over their lifespan. Testimonials from seasoned industry practitioners highlight a common theme these machines are an integral component of a successful and adaptive construction strategy.

In the competitive landscape of construction, where standing out means offering unparalleled value and quality, adopting a trapezoid roof sheet roll forming machine is a strategic move. It not only underscores a commitment to innovation but also assures clients of a construction partner who values precision and reliability. By aligning with the principles of Experience, Expertise, Authoritativeness, and Trustworthiness, businesses can enhance their reputation and expand their market influence. This forward-thinking approach to roofing technology not only addresses current challenges but also anticipates future needs in an ever-evolving industry landscape.