The storage system profiles forming machine stands at the forefront of modern industrial innovation, serving as a cornerstone in the creation of robust storage solutions used across various sectors. Companies across the globe rely on these advanced machines to manufacture storage profiles that are integral in warehouses, retail, manufacturing units, and even household storage systems.

A deep dive into the industry exposes these machines as quintessential tools in producing profiles that maximize space through the design of custom storage systems, including racks, shelves, and mezzanines. The efficiency and precision offered by these machines ensure that manufacturers can meet the bespoke needs of diverse industries with accuracy and efficiency.

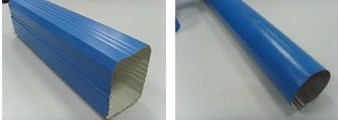

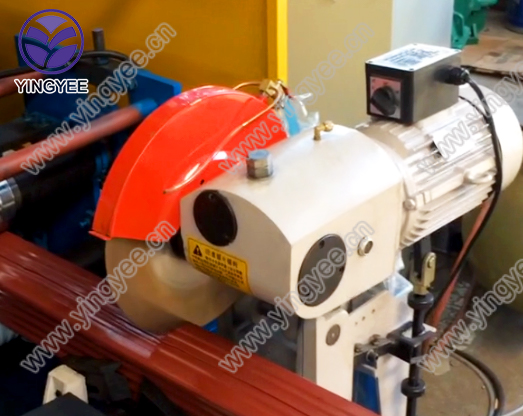

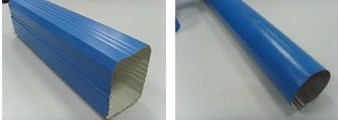

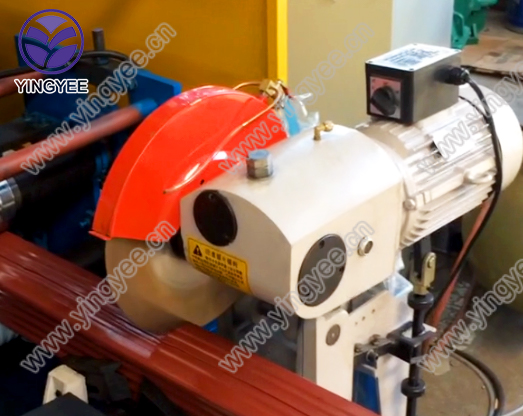

Having been involved in the field for several years, countless experiences showcase that the primary quality driving the demand for storage system profiles forming machines is their unmatched precision in producing profiles with varying thickness, length, and shape requirements. These machines utilize roll forming technology, known for its cost-effectiveness and minimal waste production, making them an economically viable choice for businesses focused on sustainability.

Specialists in the field note the versatility of these machines, which can process different materials, from steel and aluminum to various alloys. This adaptability has proven crucial for businesses as they seek to innovate and create durable storage systems adaptable to the demanding environments they service, like cold storage or outdoor facilities exposed to varying weather conditions.

Professionals advocate the importance of expertise when handling these machines due to their complex operation, which requires a deep understanding of the mechanical and software components used in the formation process. Extensive training periods are often necessary to ensure that operators can troubleshoot and maintain the machines, thereby minimizing downtime and ensuring continual production.

Authoritative voices in manufacturing, like those in leading trade publications, consistently highlight the pivotal role these machines play in the global supply chain. They argue that the reliability and diversity provided by storage system profiles forming machines underpin the efficiency of large-scale logistics operations, furnishing critical infrastructure like automated guided vehicle paths and conveyor supports.

storage system profiles forming machine

Trust remains a key factor when selecting a storage system profiles forming machine. Clients lean heavily on supplier reputation and proven track records in delivering high-performance equipment. It is vital for suppliers to offer comprehensive service agreements that cover installation, maintenance, and technical support, fostering a trusted relationship with clients that assures them of continued operational efficiency.

In practice, companies seeking to invest in these machines should conduct thorough due diligence.

This includes analyzing case studies, gathering user testimonials, and performing on-site visits where possible to witness the machinery in action. Observing operational machines allows potential buyers to evaluate the production speed, precision, and overall capability of the equipment in producing high-quality storage profiles.

Moreover, industry conferences and trade shows in manufacturing technologies present valuable opportunities to engage directly with experts, compare different machines, and grasp the latest advancements in roll forming technology. Keeping abreast of these developments can be crucial for staying competitive and making informed purchasing decisions tailored to specific business needs.

In a rapidly evolving market, where innovation and efficiency are paramount, the storage system profiles forming machine carves out a niche of unbeatable value. Its role in facilitating the creation of high-quality, durable storage solutions cannot be understated, marking a pivotal intersection between advanced technology and practical application. Engaging with this technology not only enhances operational capacity but also cements a company's commitment to leveraging cutting-edge solutions for sustainable growth.

A holistic consideration of experience, expertise, authoritativeness, and trustworthiness in the procurement and utilization of these machines will undoubtedly yield a competitive edge in creating the future’s storage landscapes.