(steel coil slitting)

Steel coil slitting transforms master coils into narrower strips with micron-level precision, serving as the foundation for producing color coated steel coils and hot dip galvanized steel coil products. The global market for slitting coil steel reached $42.7 billion in 2023, with a 5.8% CAGR projected through 2030. This process enables manufacturers to create tailored widths for applications ranging from appliance casings (0.3-2.0mm thickness) to structural components (2.5-6.0mm).

Modern slitting lines achieve ±0.005" tolerances through:

These innovations enable processing speeds up to 1,200 fpm while maintaining surface integrity for sensitive materials like pre-painted steel.

| Parameter | Company A | Company B | Industry Avg. |

|---|---|---|---|

| Width Accuracy | ±0.003" | ±0.005" | ±0.008" |

| Max Line Speed | 1,500 fpm | 1,200 fpm | 900 fpm |

| Material Thickness Range | 0.01-0.25" | 0.02-0.20" | 0.03-0.18" |

Advanced slitting services now offer:

This flexibility reduces lead times by 40% compared to traditional batch processing.

A Tier 1 supplier achieved 23% material cost reduction through:

The solution eliminated 850 tons of annual scrap while meeting ISO/TS 16949 standards.

Modern slitting operations demonstrate:

Emerging technologies like plasma-assisted edge trimming and blockchain-enabled quality tracking are reshaping steel coil processing. Manufacturers adopting these solutions report 31% faster time-to-market for new products while maintaining ASME SA-109 compliance. The integration of IoT sensors now enables real-time thickness monitoring (±0.0001" accuracy), positioning steel coil slitting

as a critical enabler for advanced manufacturing ecosystems.

(steel coil slitting)

A: Steel coil slitting is a process that cuts wide steel coils into narrower strips using rotary blades. It ensures precise width measurements and smooth edges for industrial applications. This method is efficient for producing customized steel strips for construction, automotive, and manufacturing.

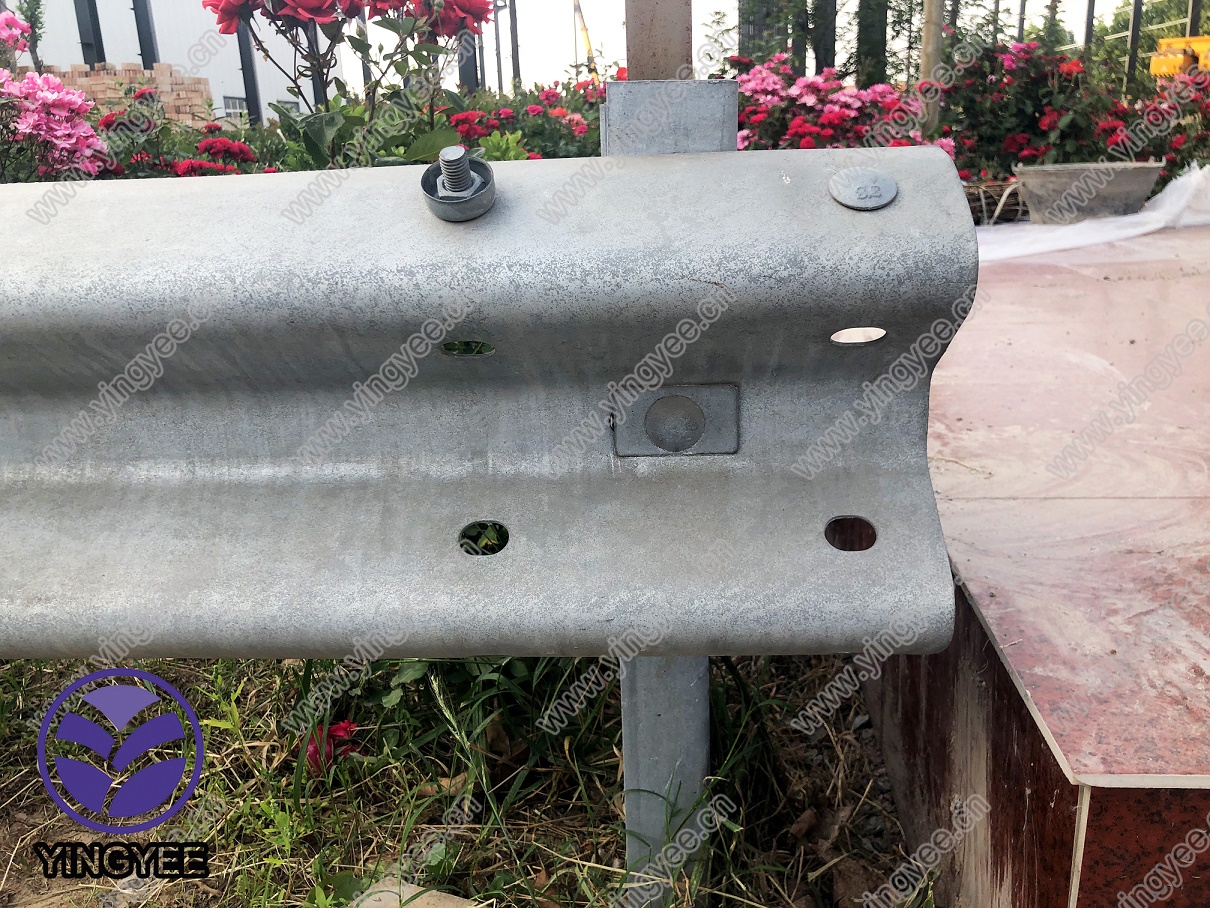

A: Yes, both color coated and hot-dip galvanized steel coils can be slit without damaging their protective layers. Specialized slitting tools and tension controls are used to maintain surface integrity. This ensures the final strips retain corrosion resistance and aesthetic qualities.

A: Key checks include verifying strip width accuracy, inspecting edge smoothness, and ensuring no surface scratches or coating damage. Tension consistency and blade alignment are monitored throughout the process. Post-slit coils are also tested for dimensional tolerances and material properties.

A: Slit coil steel is used to produce components like automotive parts, HVAC systems, and metal furniture. Its narrower width allows for easier handling and processing in stamping or roll-forming machines. This reduces material waste and improves production efficiency.

A: Hot-dip galvanized coils have a zinc layer for corrosion resistance, requiring blades that minimize heat generation. Color coated coils feature a painted surface, needing gentle handling to avoid scratches. Both require tailored slitting parameters to preserve their unique properties.