The roof tile production line is a fascinating blend of art and engineering, shaping the future of modern construction. With technological advancements and innovative approaches, a production line designed for manufacturing roof tiles is more efficient and sustainable than ever before. The process, expert insights, and reliability of roof tile production lines provide an engaging look at how roofing materials are crafted to meet the growing demand for durable and aesthetically pleasing homes.

At its core, a roof tile production line is a symphony of processes that transform raw materials into robust roofing tiles. The journey begins with selecting high-quality raw materials such as clay, concrete, or a mixture of natural and synthetic substances. These components are meticulously measured and mixed to ensure consistency and quality in every tile produced. The precise control over the raw materials exemplifies the expertise exercised in creating a premium product.

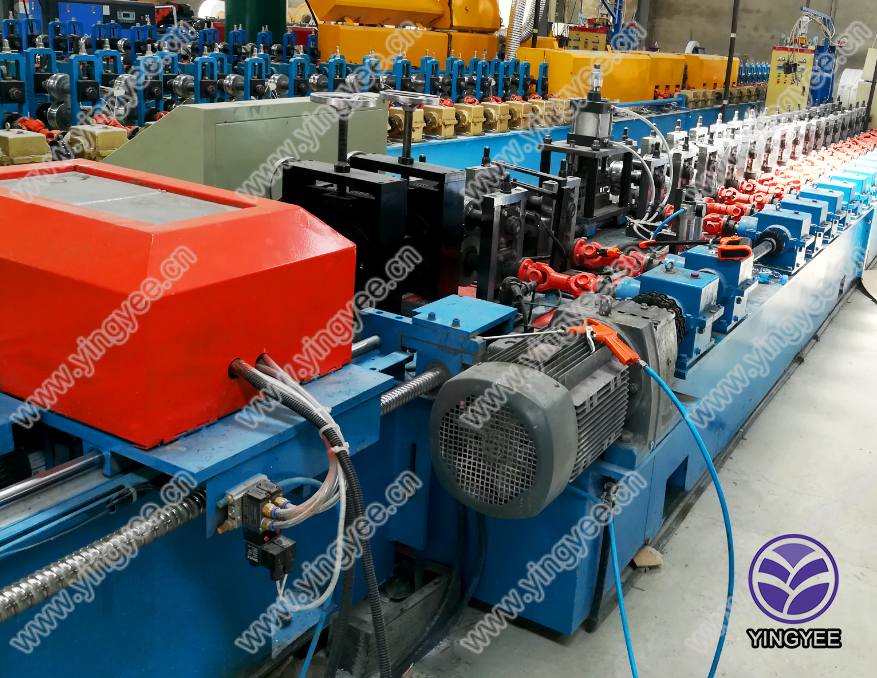

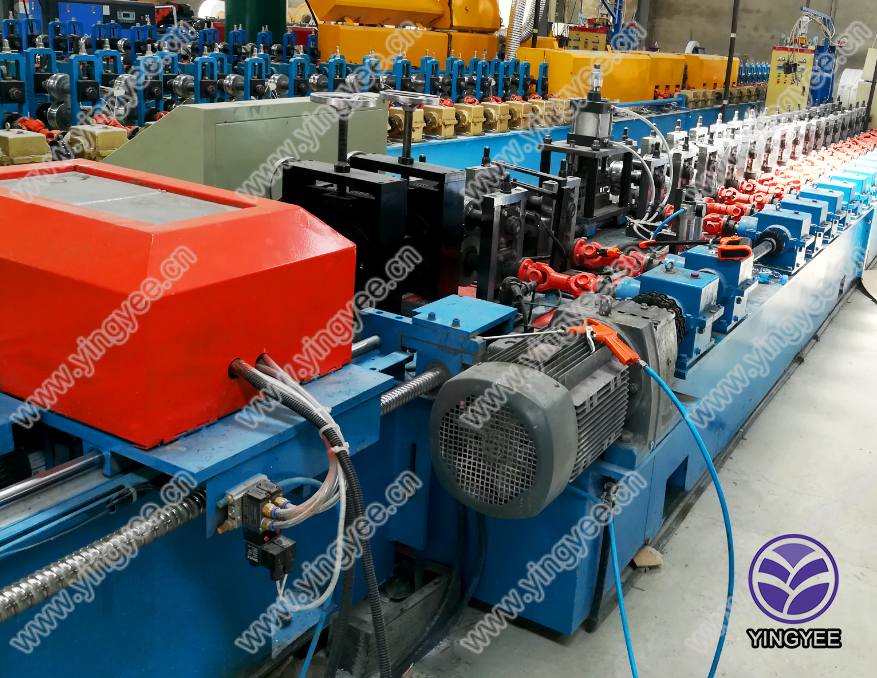

One of the defining aspects of a state-of-the-art roof tile production line is its automation. Modern production lines employ advanced machinery that streamlines the manufacturing process from start to finish. Automation not only boosts efficiency but also enhances the precision of each tile created. Cutting-edge robotic arms and CNC machines are employed to shape, cut, and mold the tiles with an accuracy that manual methods cannot match. This technological sophistication showcases the authoritative command over the production process, ensuring each tile meets strict industry standards.

Kilns play a pivotal role in the production line as they provide the necessary heat treatment to harden and strengthen the tiles. The temperature and duration of the firing process are carefully controlled, reflecting a deep understanding of the chemical changes occurring within the material. This stage is crucial in imparting the required durability and weather-resistance properties to the tiles, making them suitable for various climates and environmental conditions.

Innovation extends beyond the production mechanisms to the tiles themselves. Many companies are now focused on producing eco-friendly roofing solutions. Sustainable materials and energy-efficient production techniques are becoming the norm, as manufacturers acknowledge their responsibility toward the environment. This progressive approach underscores the trustworthiness of companies committed to reducing their carbon footprint while delivering high-quality products.

roof tile production line

Moreover, the aesthetic dimension of roof tiles is an area where expertise truly shines. Production lines are equipped to produce a wide variety of tile shapes, textures, and colors. From traditional terracotta and slate appearances to contemporary glazed finishes, the customization options are extensive, allowing architects and builders to choose tiles that best suit their design visions. Such versatility and customization capabilities are testaments to the industry’s dedication to providing solutions tailored to individual client needs.

Quality control is integral to a reputable roof tile production line. Rigorous testing protocols are in place to ensure each tile’s structural integrity, color consistency, and dimensional accuracy. Quality assurance teams conduct regular inspections at multiple stages of production, further emphasizing the credibility of the operations. This meticulous attention to detail fosters confidence among consumers and construction professionals alike, knowing they are investing in a reliable and high-caliber product.

The future of roof tile production lines is poised for even greater advancements. The integration of artificial intelligence and machine learning is set to revolutionize quality assessment, predictive maintenance, and supply chain optimization. These technologies hold the potential to mitigate production bottlenecks, reduce waste, and lower costs, thereby enhancing the overall efficiency and sustainability of roof tile manufacturing processes.

In conclusion, the roof tile production line exemplifies a melding of tradition and innovation. From the expertise ingrained in material selection and kiln processes to the authoritative control exerted by automation and the pursuit of sustainability, each aspect of the production line is underpinned by a commitment to excellence. The ongoing evolution of production methodologies and emerging technologies promises a future where roof tiles will continue to meet the highest standards of quality, aesthetics, and environmental stewardship, confirming the trust placed in these essential building materials.