(purlin roll forming machine manufacturer)

The global demand for steel framing systems has surged by 18% since 2020, driving innovation among purlin roll forming machine manufacturer

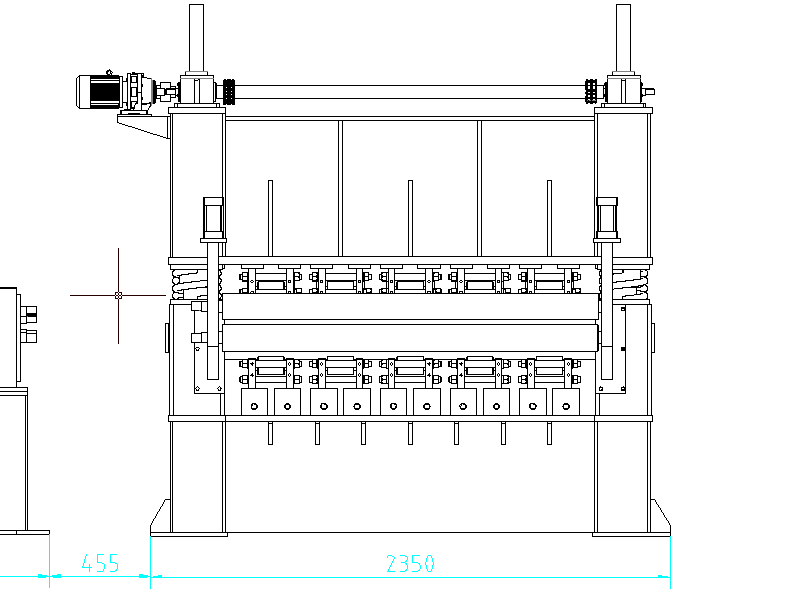

s. These specialized manufacturers combine precision engineering with automated workflows to deliver equipment capable of producing C/Z/U-shaped purlins at speeds exceeding 45 meters per minute. Advanced servo-controlled systems now achieve thickness tolerances of ±0.1mm, ensuring structural consistency for roofing and wall support applications.

Leading purlin machine manufacturers integrate these critical features:

Recent upgrades include IoT-enabled predictive maintenance modules that decrease unplanned outages by 72% compared to 2018 models.

| Parameter | ABC Manufacturing | XYZ Tech Solutions | CZ Purlin Specialists |

|---|---|---|---|

| Max Production Speed | 32 m/min | 38 m/min | 47 m/min |

| Material Thickness Range | 0.7-3.0mm | 0.5-3.5mm | 0.4-4.2mm |

| Tooling Change Time | 120 min | 90 min | 55 min |

Reputable cz purlin machine manufacturers offer modular designs supporting:

Customization options extend to material handling integrations, with some systems achieving 98% material utilization through AI-guided nesting algorithms.

A 2023 implementation for a Dubai warehouse complex demonstrated:

Similar results were replicated in automotive plant expansions across Germany and Southeast Asia.

Partnering with certified purlin roll forming machine manufacturers ensures access to R&D-driven improvements and localized technical support networks. Leading providers now offer performance-guaranteed contracts covering 92% of operational components for 5+ year periods, reflecting confidence in equipment durability and manufacturing expertise.

(purlin roll forming machine manufacturer)

A: Prioritize manufacturers with proven industry experience, certifications, and a portfolio of successful projects. Evaluate their customization options, after-sales support, and compliance with international quality standards.

A: CZ purlin machine manufacturers specialize in producing equipment tailored for C/Z-shaped purlins, offering advanced automation, precision engineering, and compatibility with diverse roofing and structural applications.

A: Yes, reputable manufacturers provide customization for material thickness, purlin dimensions, and production speed. Share your project specifications to ensure the machine meets your exact requirements.

A: Most manufacturers offer routine maintenance packages, spare parts supply, and troubleshooting support. Confirm the availability of technical assistance and service response times before purchasing.

A: Reputable manufacturers often provide 1-3 year warranties covering mechanical and electrical components. Ensure warranty terms, including coverage scope and claim procedures, are clearly outlined in the contract.