The Gutter Making Machine Efficiency and Innovation in Construction

In the realm of modern construction, efficiency and precision are paramount. One of the key tools that have gained popularity in recent years is the gutter making machine. This innovative equipment specializes in the production of seamless gutters that are essential for effective rainwater management in residential and commercial buildings. This article delves into the workings, benefits, and advancements of gutter making machines in today’s construction industry.

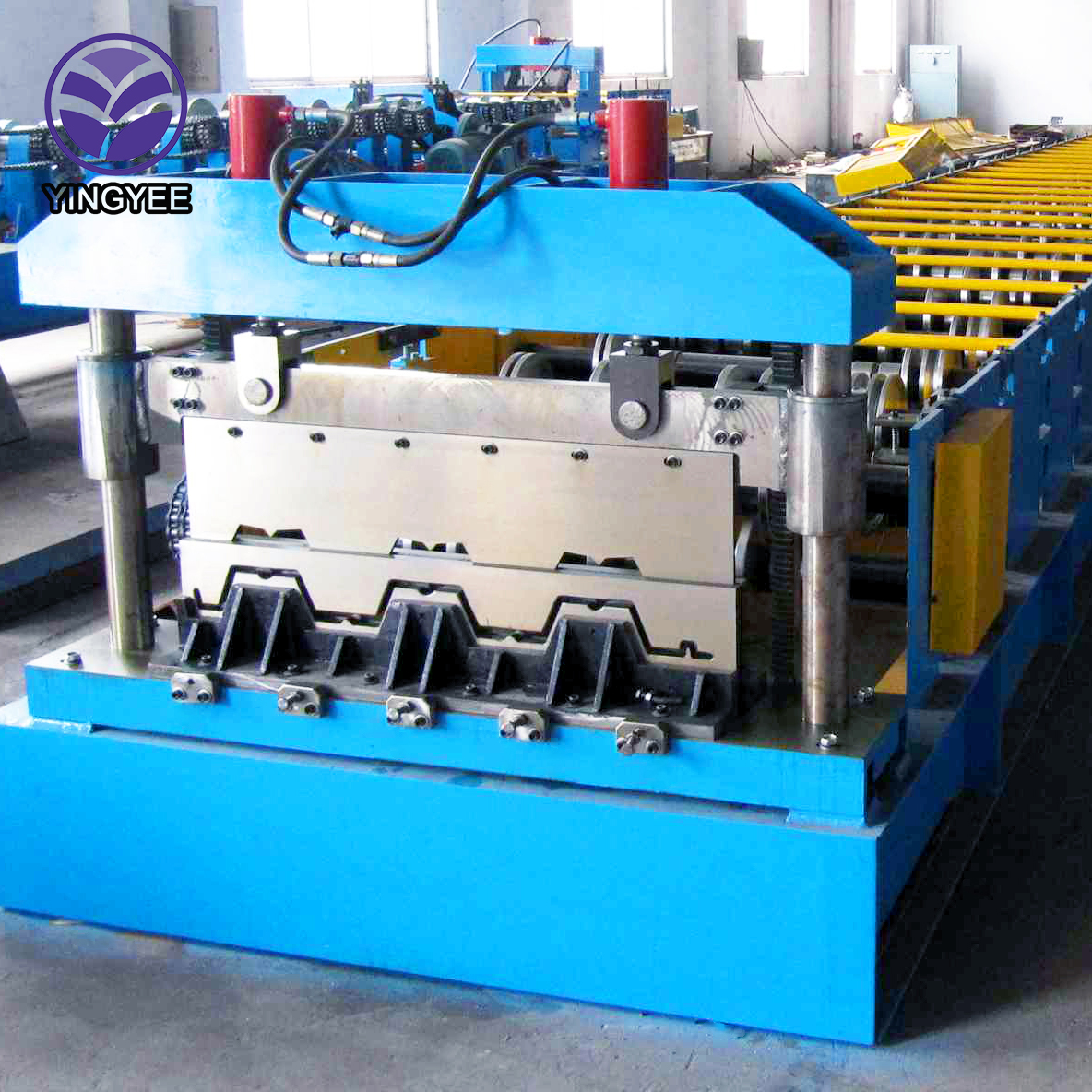

Understanding the Gutter Making Machine

A gutter making machine is designed to fabricate metal gutters on-site, providing a seamless solution that is tailored to the specific dimensions of a building. Typically, these machines utilize materials such as aluminum, steel, or copper, which are rolled into shape using a series of rollers and cutting tools. The machine operates by taking a flat sheet of material, feeding it through rollers that progressively shape it into a gutter profile, and cutting it to the required length. This process not only ensures a perfect fit but also significantly reduces waste compared to traditional gutter installation methods.

Key Features and Advantages

1. Customization One of the standout features of gutter making machines is their ability to produce gutters in various profiles and sizes. This capability allows contractors to tailor the gutter systems to specific architectural designs, ensuring aesthetic appeal while maintaining functionality.

2. Efficiency Traditional methods of gutter installation often involve pre-manufactured sections that may require additional cutting and fitting on-site. The gutter making machine streamlines this process by enabling real-time production, which saves time and labor costs. Builders can install seamless gutters in a fraction of the time it would take to assemble individual components.

3. Quality Control Using a gutter making machine helps maintain a high level of quality control. By producing gutters on-site, contractors can ensure that the materials used are of high quality, and the manufacturing process is closely monitored. This reduces the likelihood of defects and enhances the lifespan of the gutters.

4. Cost-Effectiveness While the initial investment in a gutter making machine may be higher than purchasing pre-fabricated gutters, the long-term savings often outweigh these costs. Reduced labor expenses and minimized material waste contribute to lower overall project costs.

5. Portability Many modern gutter making machines are designed to be portable, allowing contractors to transport them easily to various job sites. This portability makes it possible to produce gutters wherever they are needed, further enhancing the efficiency of the installation process.

Technological Advancements

The gutter making industry has seen significant technological advancements in recent years. Modern machines are equipped with computer numerical control (CNC) technology, which allows for precise adjustments and programming for different gutter profiles. Additionally, some machines are now integrated with automation systems that can monitor the production process, ensuring consistent quality and reducing the potential for human error.

Moreover, advancements in material science have led to the development of thicker, more durable materials that can withstand harsh weather conditions. This has expanded the applications of gutter making machines beyond residential projects, making them ideal for commercial and industrial construction as well.

Environmental Considerations

As sustainable construction practices become increasingly vital, gutter making machines offer an eco-friendly advantage. By producing seamless gutters on-site, construction waste is significantly reduced. Moreover, the utilization of recyclable materials like aluminum and copper further enhances the environmental benefits, contributing to greener building practices.

Conclusion

The gutter making machine represents a significant advancement in the construction industry, combining efficiency, quality, and sustainability. As builders and contractors continue to seek ways to improve their processes, these machines are poised to become essential tools in the construction arsenal. With their ability to provide customized, high-quality gutters on-site, they not only enhance project efficiency but also contribute to the overall aesthetic and functional value of buildings. As technology continues to evolve, the gutter making machine will undoubtedly adapt, further cementing its place in the future of construction.