The Gutter Cutting Machine A Revolution in Construction and Landscaping

In the world of construction and landscaping, precision and efficiency are two essential elements that can greatly impact the quality of work and overall project timelines. One innovative tool that has emerged to meet these needs is the gutter cutting machine, designed specifically for the efficient installation of gutters and drainage systems. This machine not only enhances productivity but also ensures accuracy, reducing the risk of errors associated with manual cutting methods.

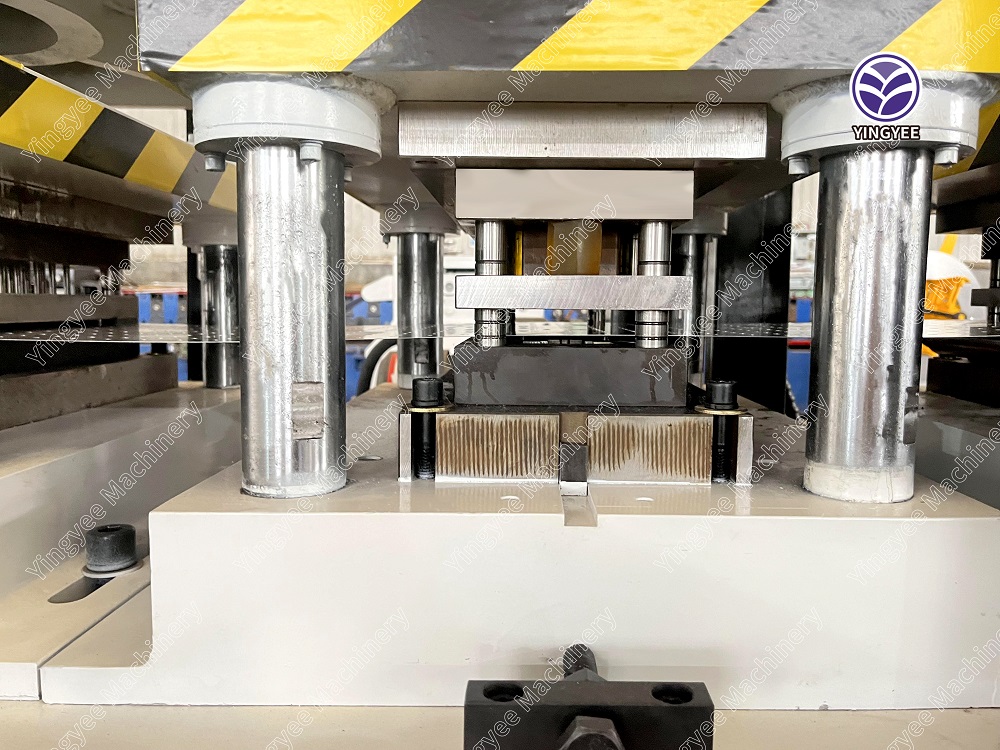

The gutter cutting machine is engineered to streamline the process of cutting various materials used in gutter systems, such as aluminum, vinyl, and steel. Traditional methods often involve labor-intensive manual cutting, which can be time-consuming and prone to mistakes. With a gutter cutting machine, users can achieve clean and precise cuts in a fraction of the time. This is particularly beneficial for contractors managing multiple projects or larger jobs, where time efficiency can lead to significant cost savings.

One of the primary advantages of using a gutter cutting machine is its ability to produce repeatable results

. The machine is designed to handle specific angles and dimensions, allowing for uniformity across all cuts. This consistency is crucial for ensuring that all gutter pieces fit together seamlessly during installation. Moreover, the precision of the cuts reduces the likelihood of leaks and other issues, contributing to the longevity and performance of the gutter system.

Another significant benefit is the reduction in labor costs. With a gutter cutting machine, fewer workers are needed to perform cutting tasks, freeing them up for other essential duties. This can lead to a more streamlined workflow and help companies maximize their resources. Additionally, safety is enhanced, as machines are typically equipped with various safety features to minimize the risk of injury that can occur with manual cutting tools.

The gutter cutting machine is also versatile, as many models can be adjusted to accommodate different materials and cutting styles. This adaptability ensures that contractors can meet a wide range of project requirements without the need for multiple tools. Furthermore, advancements in technology have led to the development of automated models that can even integrate with computer-aided design (CAD) systems, allowing for precise measurements and cutting based on digital plans.

In conclusion, the gutter cutting machine represents a significant advancement in the construction and landscaping industries. By improving cutting precision, efficiency, and safety while reducing labor costs, it enables contractors to deliver high-quality work more quickly. As the demand for efficient and effective construction solutions continues to rise, the gutter cutting machine is becoming an indispensable tool in the toolkit of modern builders and landscapers.