Outline:

(punch press company)

Industrial fabrication demands precision machinery capable of meeting tight tolerances while maintaining cost efficiency. Established punch press companies serve as innovation hubs, combining mechanical engineering with digital automation to transform raw materials into complex components. The sector has experienced 17% growth since 2020, driven by aerospace, appliance manufacturing, and renewable energy sectors requiring high-volume precision stamping.

Modern production facilities utilizing turret punch presses report 30-40% faster setup times compared to traditional methods, significantly reducing downtime between jobs. This operational efficiency directly impacts profitability metrics, with automated feeding systems increasing material utilization rates to 94% across leading manufacturers. Such advancements position progressive punch press companies as essential partners in supply chain optimization.

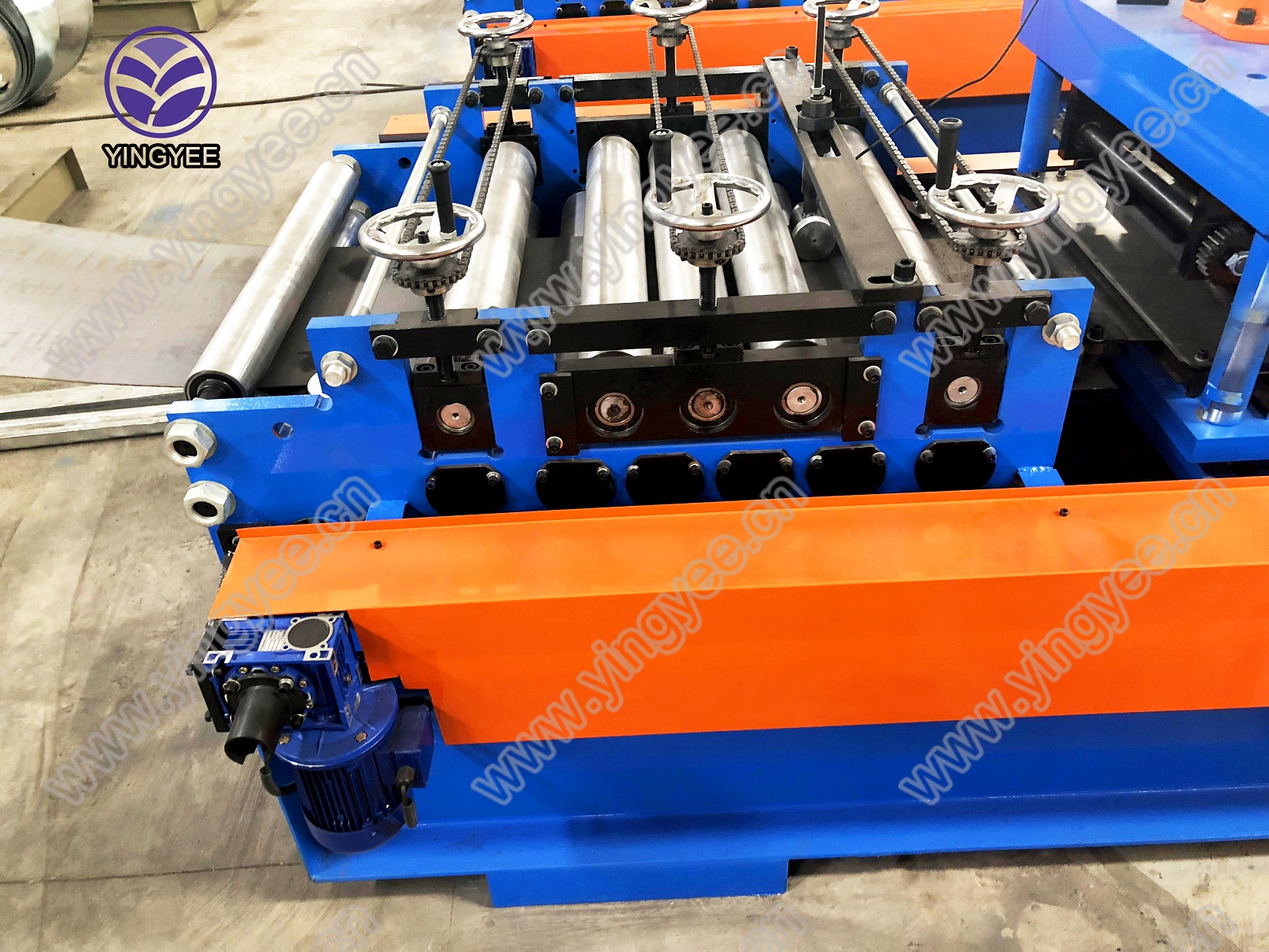

Contemporary CNC punch press systems incorporate multifaceted technological improvements that redefine production benchmarks. Servo-electric models deliver 68% energy reduction over hydraulic predecessors while providing ±0.05mm repeatability across continuous operations. Automatic tool changers enable complex geometries with multi-stage forming capabilities that previously required separate processing stations.

Advanced sensor integration monitors tool wear in real-time, reducing scrap rates by 23% in average production cycles. Programmable axis controls combined with 3D simulation software eliminate trial runs, translating CAD designs directly into production without intermediate prototyping. High-yield configurations now process 1,200+ sheet metal components per hour while maintaining consistent quality standards through predictive maintenance algorithms.

| Specification | Standard Industrial Grade | Precision Engineering Series | High-Speed Production Systems |

|---|---|---|---|

| Maximum Tonnage | 30-100 tons | 25-80 tons | 50-220 tons |

| Strokes Per Minute | 70-150 SPM | 40-90 SPM | 400-1,000 SPM |

| Material Thickness | 0.5-6.0 mm | 0.2-3.0 mm | 0.4-12.7 mm |

| Positioning Accuracy | ±0.1 mm | ±0.02 mm | ±0.07 mm |

| Tool Change Time | 45-90 seconds | 120-300 seconds | Under 5 seconds |

Performance variations depend significantly on tooling packages and control systems. Precision engineering models sacrifice speed for microscopic accuracy required in optical and medical applications, while high-speed configurations prioritize throughput for automotive components. Production volume requirements primarily determine which configuration delivers optimal ROI.

Pre-painted galvanized iron (PPGI) presents unique processing challenges that demand specialized solutions from experienced equipment providers. Punch press companies have developed proprietary tool geometries and stripper mechanisms to prevent coating separation during forming operations. Optimized die clearance parameters maintain corrosion protection integrity while achieving complex bends impossible with conventional press brakes.

Dedicated PPGI production lines incorporate scratch-resistant conveyor systems with vacuum handling that eliminates surface contact on coated surfaces. Dry-film lubrication systems specifically formulated for painted metals enable higher punching speeds without compromising edge quality. Facilities regularly processing coated metals achieve ≤0.8% material waste rates through such specialized approaches that preserve the substrate's protective properties.

Forward-thinking punch press companies collaborate on integrated manufacturing approaches rather than standalone equipment sales. Custom workholding solutions account for dimensional instability in specialty alloys used in aerospace applications, with thermal compensation algorithms adjusting parameters in real-time. Modular press configurations combine bending, embossing, and tapping stations to create finished products without secondary handling.

Adaptive manufacturing programs utilize automated press monitoring to deliver component cost reductions of 14-22% annually through continuous process refinement. Client-specific software integrations synchronize press operations with inventory management, triggering tool changes based on scheduled production orders. Such customized approaches transform standalone equipment into comprehensive production ecosystems.

HVAC component manufacturers increased output 60% after implementing tandem press lines with automated transfer systems, reducing direct labor costs while eliminating handling damage. The automated punch press configuration cut changeover times from 37 minutes to under 90 seconds while accommodating 65% material diversity across production schedules. Engineering changes implemented by the equipment provider increased tool lifespan by 300% when processing hardened stainless steel.

Commercial appliance producers achieved 99.3% first-pass quality rates on complex door panels after transitioning to direct-drive punching systems with optical alignment verification. Custom nesting algorithms implemented by their manufacturing partner reduced aluminum scrap rates from 8.2% to 2.6%, saving $300,000 annually in reclaimed material costs while meeting enhanced cosmetic standards demanded in consumer markets.

Identifying a qualified punch press company

requires thorough technical evaluation beyond basic specification comparisons. Proven project engineers should demonstrate process optimization experience specific to your materials and volumes, providing quantifiable metrics rather than theoretical advantages. Request production cell validation with your actual components prior to equipment commitment to observe dimensional stability under sustained operation.

Establish partnerships that include productivity tracking software to monitor throughput efficiency, tool wear patterns, and energy consumption per component. Top-tier suppliers back their systems with performance guarantees indexed to output targets, ensuring equipment specifications translate directly into production results. This collaborative approach positions the automatic punch press as the cornerstone of ongoing manufacturing advancement rather than a standalone capital expenditure.

(punch press company)

A: A punch press company provides industrial punching machinery for metal fabrication, including manual, CNC, and hydraulic punch presses. These machines create precise holes and shapes in sheet metal. Many companies also offer dies, accessories, and maintenance services.

A: Automatic punch presses significantly boost productivity by enabling unattended operation with robotic part handling and programmable tool changes. They reduce labor costs and minimize errors through computer-controlled precision positioning. Cycle times are shortened while maintaining consistent part quality.

A: Yes, punch presses excel at processing PPGI (pre-painted galvanized iron) sheets for roofing, panels, and appliances. Specialized tooling prevents coating damage during punching operations. Computer-guided systems ensure accurate hole placement without compromising the protective zinc layer or paint finish.

A: Prioritize tonnage capacity for material thickness, bed size for workpiece dimensions, and T-slot tooling compatibility. Evaluate control system sophistication like CAD file import and automatic nesting capabilities. Essential automation features include robotic part manipulation and quick-change tool magazine systems.

A: Leading suppliers offer custom tooling designed to cleanly punch pre-coated metals without delamination. They provide pressure-adjusted systems to prevent PPGI surface deformation. Many companies conduct material-specific testing to optimize punching parameters for corrosion-resistant finishes.