The Nut and Bolt Large Span Roll Forming Machine with Bending Machine A Comprehensive Overview

In the modern manufacturing landscape, efficiency, precision, and versatility are paramount. The nut and bolt large span roll forming machine combined with a bending machine stands as a crucial innovation that addresses the needs of industries requiring high-quality metal components. This article delves into the intricacies of this machinery, its working principles, applications, and the advantages it brings to the manufacturing sector.

Understanding Roll Forming Technology

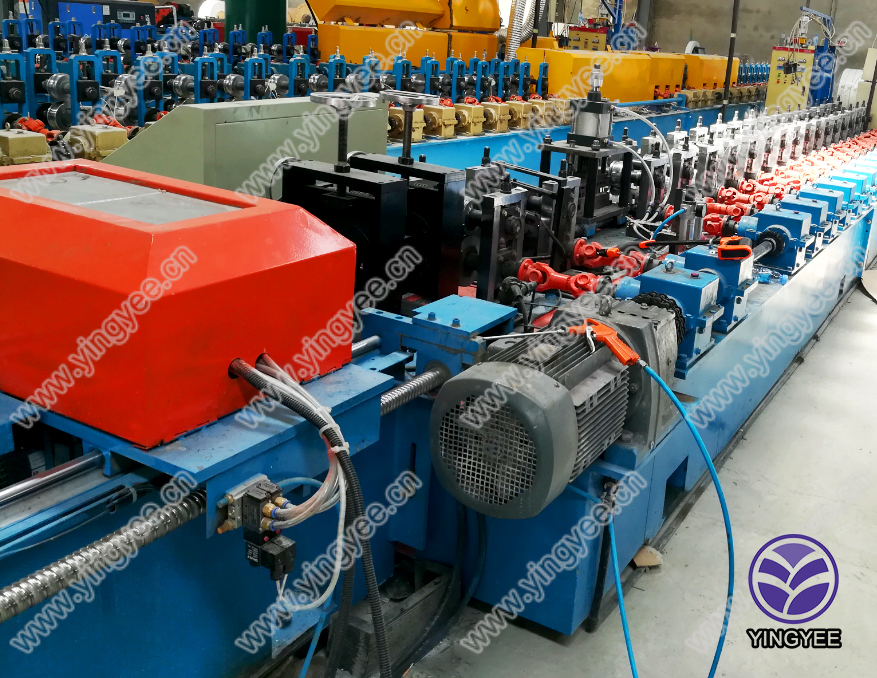

Roll forming is a continuous bending operation in which a long strip of metal is passed through a series of rollers, each performing a small bend until the desired cross-section is achieved. This technique is highly efficient for producing parts with uniform profiles over extensive lengths. The nut and bolt large span roll forming machine specializes in creating components used widely in construction, automotive, and heavy machinery sectors. Its capability to produce large spans makes it an ideal choice for manufacturers looking to meet varying customer demands.

The Role of Bending Machines

While roll forming excels in shaping metal strips into specific profiles, the bending machine complements this process by allowing for the creation of complex shapes and angles. This dual functionality enables manufacturers to produce finished products that require both consistent profiles and intricate bends, streamlining the production process and reducing the need for multiple machines.

Applications Across Industries

The nut and bolt large span roll forming machine with bending capabilities can fabricate a wide range of products. In the construction industry, it is used to create structural components such as girders, beams, and connectors. In the automotive sector, this machine can produce brackets, frames, and supports critical to vehicle integrity and performance. Furthermore, this equipment plays a vital role in manufacturing components for appliances and machinery, highlighting its versatility.

Benefits of Integrated Systems

Integrating roll forming and bending processes into a single system offers numerous advantages

1. Cost Efficiency By reducing the number of machines required for the production process, manufacturers can significantly lower operational costs. Less machine investment translates to lower maintenance, utility, and labor costs.

2. Increased Productivity Combined systems minimize the handling time between different processes. The manufacturing line can operate at a higher speed, leading to increased output and quicker turnaround times for customer orders.

3. Enhanced Precision The alignment and consistency provided by integrated machines lead to higher quality products. Precise bending ensures that parts fit together seamlessly, reducing the need for adjustments during assembly.

4. Customization Manufacturers can easily adapt and modify production runs based on specific customer needs. The ability to change profiles and bends quickly makes it feasible to process small-batch orders alongside larger runs without significant downtime.

5. Versatile Applications This technology can be applied to various materials, including steel, aluminum, and specialty alloys. As a result, manufacturers can expand their product offerings across different sectors.

Conclusion

The nut and bolt large span roll forming machine with bending capabilities represents a significant advancement in metal fabrication technology. By combining the efficiency of roll forming with the flexibility of bending, this integrated system offers manufacturers a powerful tool to enhance productivity, reduce costs, and improve product quality. As industries continue to evolve, the importance of such innovative technologies will undoubtedly grow, shaping the future of manufacturing. Adopting these machines will equip manufacturers to meet the ever-changing demands of the market while maintaining their competitive edge.