The Evolution and Importance of Corrugated Roof Roll Forming Machines

In recent years, the construction industry has witnessed significant advancements in manufacturing technologies, one of which is the development of corrugated roof roll forming machines. These machines are essential for producing high-quality corrugated roofing sheets efficiently and effectively. With increasing demands for durable and cost-effective roofing solutions, understanding the capabilities and benefits of these machines is crucial for both manufacturers and builders.

What is a Corrugated Roof Roll Forming Machine?

A corrugated roof roll forming machine is a specialized piece of equipment designed to manufacture corrugated sheets from flat metal coils, typically made from materials like galvanized steel, aluminum, or other alloys. The process begins with feeding the metal coil into the machine, where it undergoes a series of precise forming operations to achieve the desired corrugated profile. The outcome is lightweight, strong, and weather-resistant sheets that are widely used in various construction projects, from residential homes to industrial buildings.

The Manufacturing Process

The manufacturing process of corrugated roofing sheets using a roll forming machine involves several stages

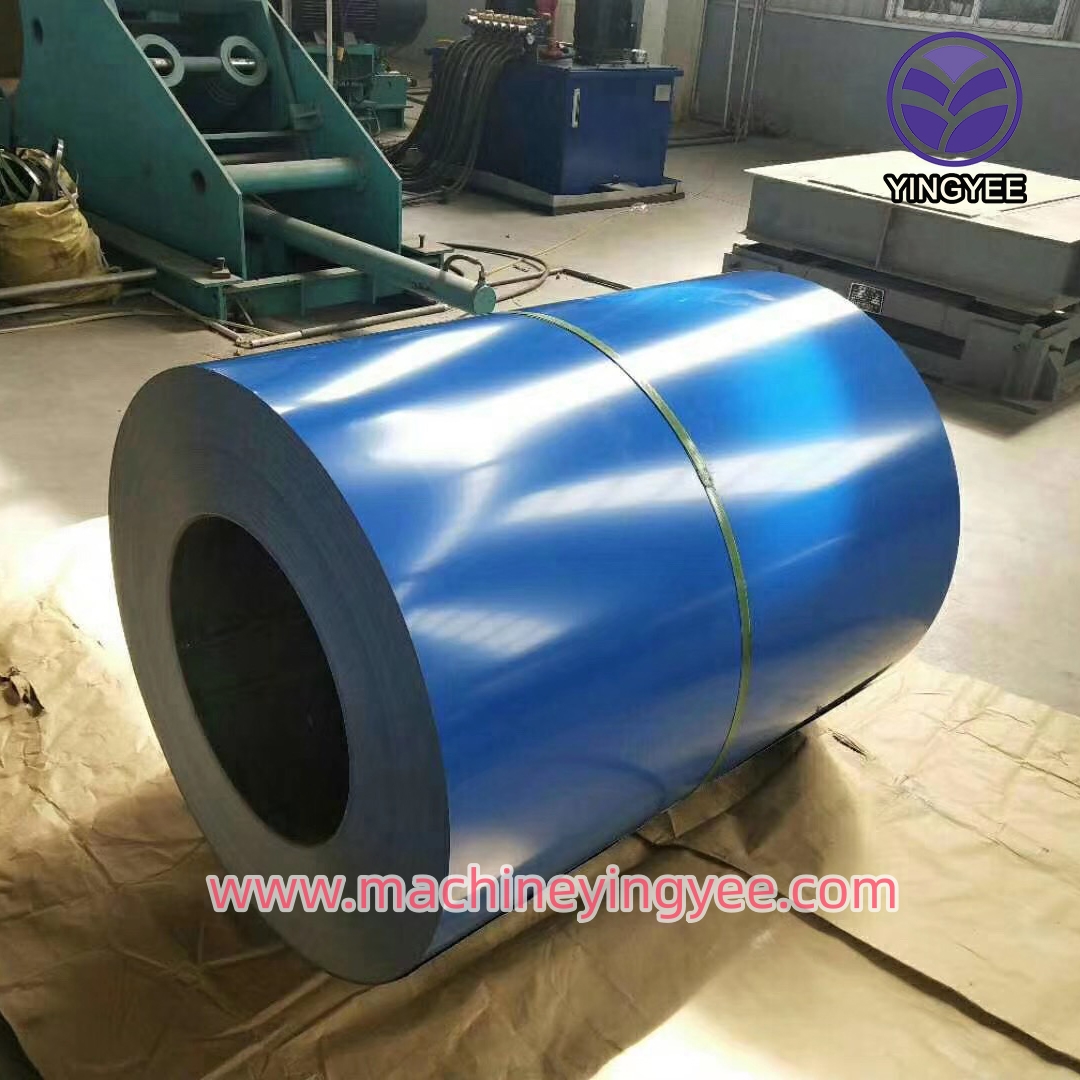

1. Coil Loading Coils of metal are loaded onto the machine. These coils are often pre-treated to enhance their durability and resistance to corrosion.

3. Roll Forming As the coil passes through a sequence of rollers, it is gradually shaped into the desired corrugated profile. The rollers are precisely spaced and contoured to create uniform waves or ridges on the sheet.

4. Cutting Once the sheet has been formed, it is cut to the required length using a hydraulic or mechanical cutting system. This ensures that each sheet produced meets the specifications of the project it’s intended for.

5. Output The finished corrugated sheets are then ejected from the machine, ready for packaging or immediate installation.

Benefits of Using Corrugated Roof Roll Forming Machines

1. Efficiency and Speed These machines are designed for high-speed production, which means that manufacturers can produce large quantities of roofing sheets in a short period. This efficiency translates to reduced labor costs and faster project completion times.

2. Customization Most modern roll forming machines offer customization options, allowing manufacturers to produce sheets of various lengths, widths, and profiles. This flexibility is particularly beneficial in meeting specific client requirements or adhering to local building codes.

3. Quality Control Roll forming technology ensures a consistent thickness and quality of the sheets produced. Advanced machines come equipped with electronic controls that monitor the production process, minimizing the chances of defects and ensuring uniformity across batches.

4. Material Optimization Corrugated roof roll forming machines create minimal waste during production. The ability to use coils efficiently reduces material costs and contributes to a more sustainable manufacturing process.

5. Versatility The end products of corrugated roof roll forming machines are not limited to roofing. The sheets can also be used in wall cladding, agricultural buildings, and even decorative applications. This versatility enhances the value of investing in such machinery.

Final Thoughts

As the construction industry continues to evolve, the demand for efficient and reliable machinery will only increase. Corrugated roof roll forming machines are at the forefront of this transformation, offering numerous advantages for manufacturers and builders alike. Investing in advanced roll forming technology not only enhances production capabilities but also contributes to the overall quality and sustainability of the construction process. Embracing these innovations will undoubtedly play a pivotal role in shaping the future of roofing solutions in the years to come.