Understanding Capping Roll Forming Machines An Essential Tool in Modern Manufacturing

In the ever-evolving landscape of manufacturing and construction, efficiency and precision are paramount. Among the various processes that contribute to these essential goals, roll forming stands out as a unique and effective method. Specifically, capping roll forming machines play a crucial role in producing metal caps that serve a variety of functions in numerous industries. This article delves into the details of capping roll forming machines, their applications, advantages, and how they have revolutionized manufacturing processes.

What is a Capping Roll Forming Machine?

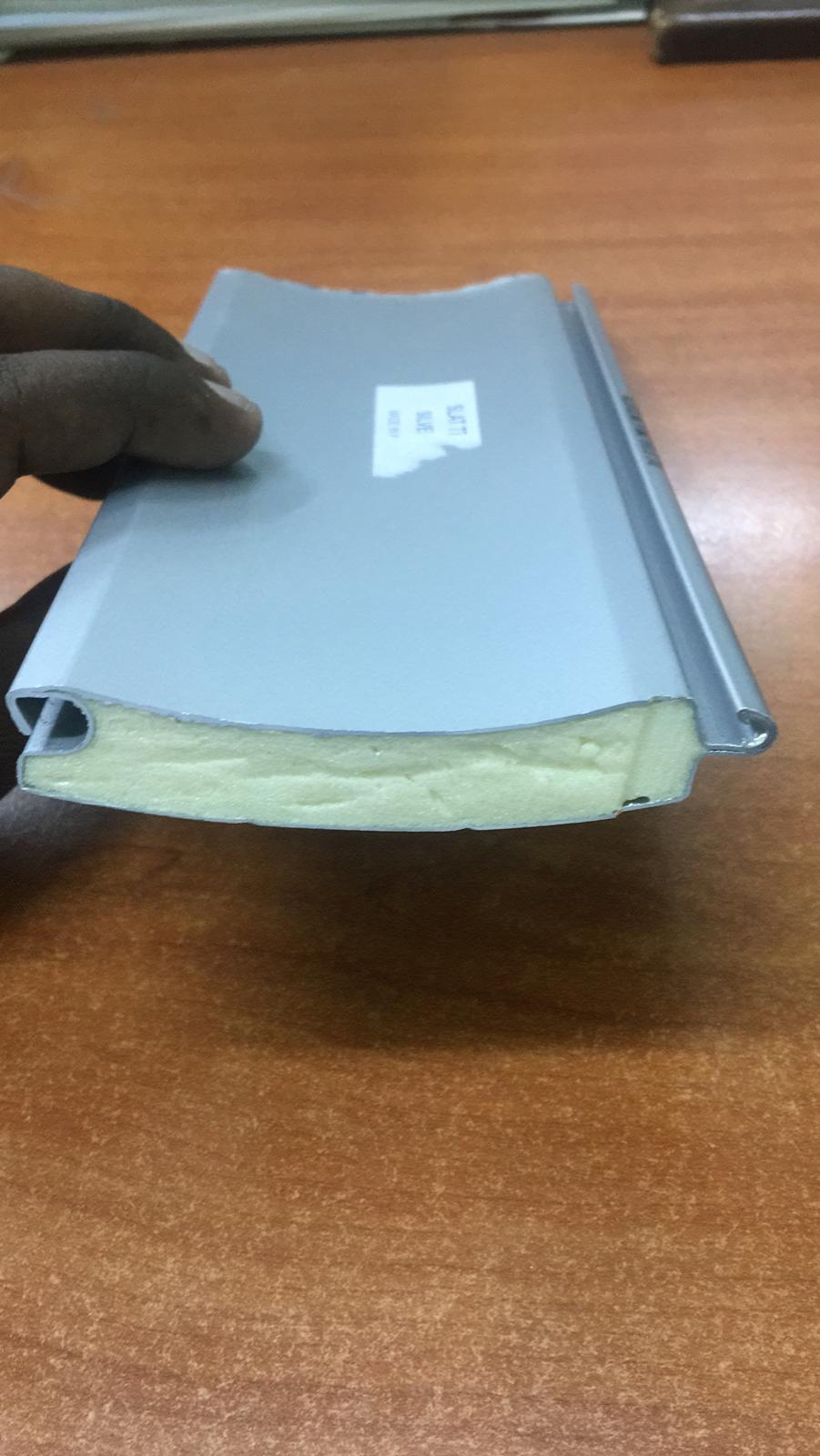

A capping roll forming machine is a specialized piece of equipment designed to shape lightweight metal strips into caps or covers using a continuous bending process. This machine takes raw metal sheets, usually made from steel or aluminum, and passes them through a series of rollers that gradually form the material into the desired shape. The result is a high-quality, uniform product that adheres to precise specifications.

The design of capping roll forming machines can vary, but they generally consist of several key components uncoilers for the raw material, roll stations that shape the metal, cutting devices to trim it to the appropriate length, and a stacker for finished products. These elements work together seamlessly to create an efficient production line that minimizes waste and maximizes output.

Applications

Capping roll forming machines are integral to various industries. One of the most common applications is in the construction sector, where metal caps are used to cover the tops of posts, beams, and other structures. These caps not only enhance the aesthetic appeal of buildings but also protect critical components from environmental damage.

In addition to construction, these machines are widely used in the manufacturing of automotive parts, electrical enclosures, and HVAC systems. For instance, in the automotive industry, capping roll forming machines produce caps that are essential for the integrity of different vehicle components. Similarly, in HVAC, they create necessary covers for ducts and vents, ensuring operational efficiency and aesthetic coherence.

Advantages of Capping Roll Forming Machines

The advantages of utilizing capping roll forming machines are substantial. First and foremost, these machines enable high production rates with minimal labor costs. Their automated nature means that once they are set up, they can operate continuously, producing thousands of caps with consistent quality. This automation helps manufacturers meet high demand without needing to hire large teams of workers.

Moreover, capping roll forming machines are known for their precision and minimal waste generation. Because the process involves bending rather than cutting, less material is wasted during manufacturing. Additionally, the ability to produce custom shapes means that manufacturers can closely tailor products to customer specifications.

The durability and strength of the products produced are also noteworthy. Metal caps shaped through roll forming exhibit excellent structural integrity, making them suitable for a wide range of applications where durability is paramount. Furthermore, the process enhances the surface finish of the final product, often eliminating the need for additional treatments.

Conclusion

Capping roll forming machines are vital to enhancing efficiency and precision in modern manufacturing. Their ability to produce high-quality metal caps for diverse applications has made them indispensable in various sectors, including construction, automotive, and HVAC. As industries continue to seek ways to optimize production and reduce waste, the role of capping roll forming technology is likely to expand, positioning it as a cornerstone of future manufacturing innovations. As manufacturers embrace this technology, we can expect to see even greater advancements in efficiency, customization, and quality in the products we use every day.